Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

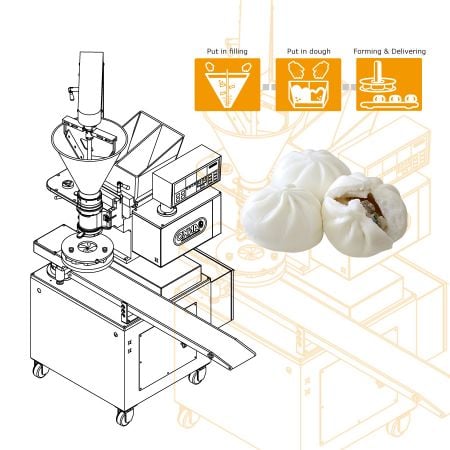

The client, a Chinese entrepreneur who moved to the Netherlands, started a restaurant specializing in authentic dumplings, famous for thin wrappers and generous fillings appealing to both the local Chinese community and Dutch customers. As the restaurant grew and expansion plans emerged, the client experimented with buns, producing them manually to test market demand. Positive feedback encouraged larger-scale production. Facing increasing orders and limited manpower, the client leveraged their experience with ANKO’s HLT-700XL machine and introduced the SD-97W Automatic Encrusting and Forming Machine, efficiently increasing output, maintaining consistent quality, and offering a wider variety of products for in-store dining and retail.

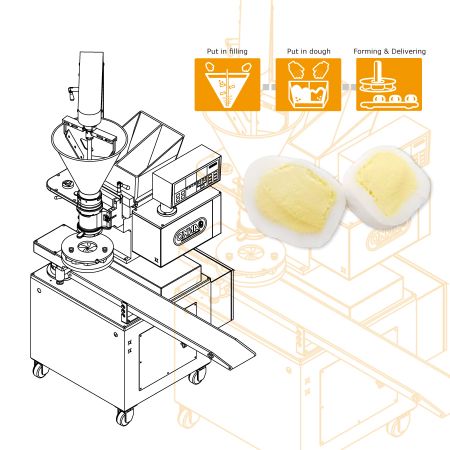

An ANKO client operates a restaurant in Los Angeles serving authentic Asian specialty foods, and Mochi is one of their best-selling desserts. Many diners enjoy ending their meals with an order of Mochi, often paired with tea or coffee. Our client wanted to increase their revenue by making their popular Mochi available for takeout, but they didn’t have enough labor to accomplish this plan. While searching for automated food machine options, this client discovered ANKO Food Tech and scheduled a machine trial. ANKO recommended using the SD-97W Automatic Encrusting and Forming machine to the client for making Mochi and Mochi Ice Cream. The client was very impressed with the machine demonstration, and the taste of the final products. Based on their volume, they decided to purchase the SD-97SS Table-Type model. After delivering the machine, our team helped the client to familiarize themselves with the production process, machine maintenance routines, and overall operations.

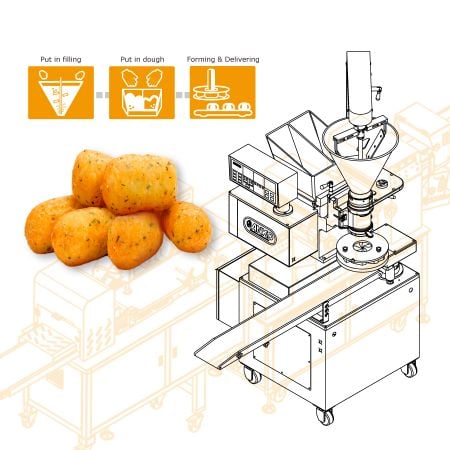

An ANKO client having had a successful food business in Colombia selling croquetas (croquette) to casinos and other retailers was looking for an opportunity to turn a vacant factory in Indonesia into a profitable automated food business. Because this client had previously purchased ANKO’s HLT-700XL, SR-24 and an ANKO commercial deep fryer, they had decided to seek ANKO’s assistance to provide them with professional automated production line equipment and support to sell croquetas (croquette) in Indonesia.

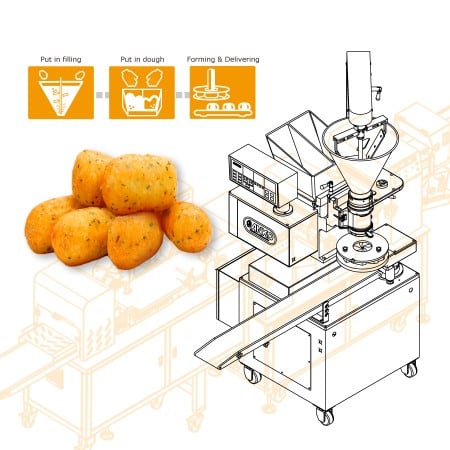

The Peruvian client is the boss of a restaurant and food factory. Our business relationship began with a compact vegetable cutting machine. As he found that ANKO's soft power in research and development as well as abundant recipes, we have become one of his consultants for solutions. The client's stuffed cassava products had been made by hand. When the demand increased to a certain amount, he was seeking a machine that provides labor saving and productivity boosting solutions. In order to ensure product quality, he came to our central kitchen in ANKO headquarters for a machine test run and face-to-face communication with our engineers regardless of the great distance. It's all for the best wrapper/filling ratio and the most appropriate recipe for automatic production.