ANKO set up a Double Line Samosa Pastry Production Line to meet the large demand during Ramadan for an Indian Client

This ANKO client is a well-known food producer and supplier in India, their frozen food and baked goods are widely distributed throughout the country. Samosa is a popular staple; it can be served as street food snacks, and they are also a key part of festive celebrations. Islam is the second largest religion in India, and Samosas are always in high demand during Ramadan. Therefore, this client was in need of professional commercial food machines that can produce high quality products in large quantities to meet the market demand. The machines they found locally could not meet their product requirements, so they contacted ANKO. Subsequently they visited ANKO’s headquarters in Taiwan. After testing ANKO’s machine with production trials, our professional teams provided many production solutions, and the client was very satisfied with our Samosa Pastry Sheet Machines.

Samosa Pastry

ANKO Team Research Problem Solving or Solution Delivery

How to solve these problems that the samosa pastry became yellow and their texture was not as delicate as required

The final products should be delicate in texture to wrap up stuffing and deliver nice-looking products to consumer's hands. In the first test, ANKO team noticed that the pastry were close to yellow. Therefore, engineers made some adjustment to solve problems. The solutions were listed below:

1. Reduce the amount of...

2. Use less...

3. Stir batter...(Please contact us to get more information)

After ANKO’s adjustments, our client was very pleased with the quality of the Samosa Pastry Sheets and made great tasting Samosas with them. When this client switched to a fully automated production system utilizing ANKO’s machines, the Samosa Pastry Sheets remained the same taste, texture, and quality.

Food Equipment Introduction

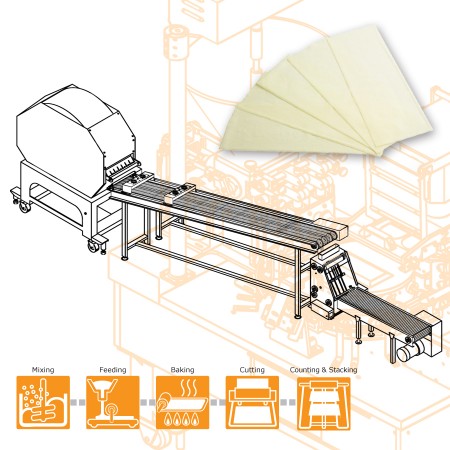

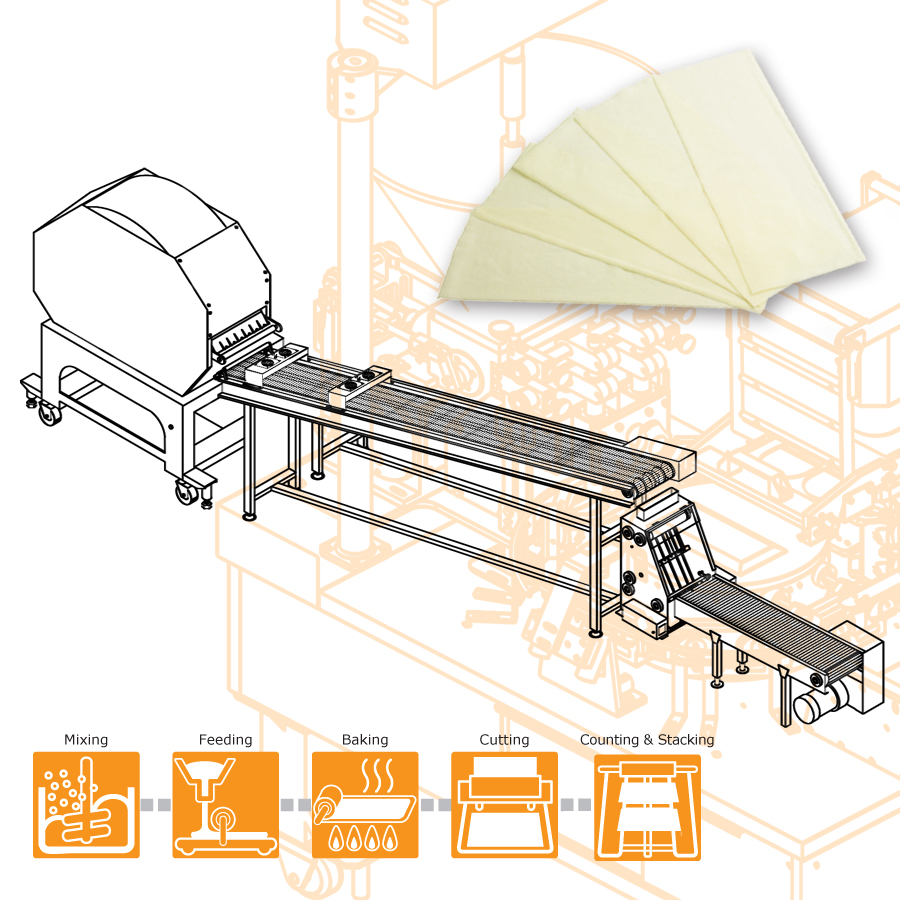

- Pour well-stirred batter into the hopper.

- Adjust settings on the control panel and make sure the temperature and condition of baking drum.

- Bake batter into a pastry belt.

- Straightly trisect the pastry belt.

- Cool it by fans.

- Cut into required length.

- Stack pastry.

Fundamental of Design

- The client would like to improve productivity of samosa. Therefore, ANKO recommended the stable and productive Automatic Spring Roll and Samosa Pastry Sheet Machine which can produce up to 16,200 pieces in one hour.

- The length and width of samosa pastry are adjustable as required through the changes of parts and settings. The unstable quality of products resulted from the handmade production can be solved.

- The automatic staking device piles pastries neatly to make the next manual wrapping process more convenient. Moreover, the quality of samosa pastry made by machine would be more stable and uniform than that made by hand.

- Product quality is of concern to the client and ANKO. We are devoted to provide consumers the safest food with best quality. As designing SRP Series machine, the client's requirements are taken into consideration. We provide stable machinery and solutions to produce products with taste and texture like handmade and satisfy individual demand.

- Solution Proposal

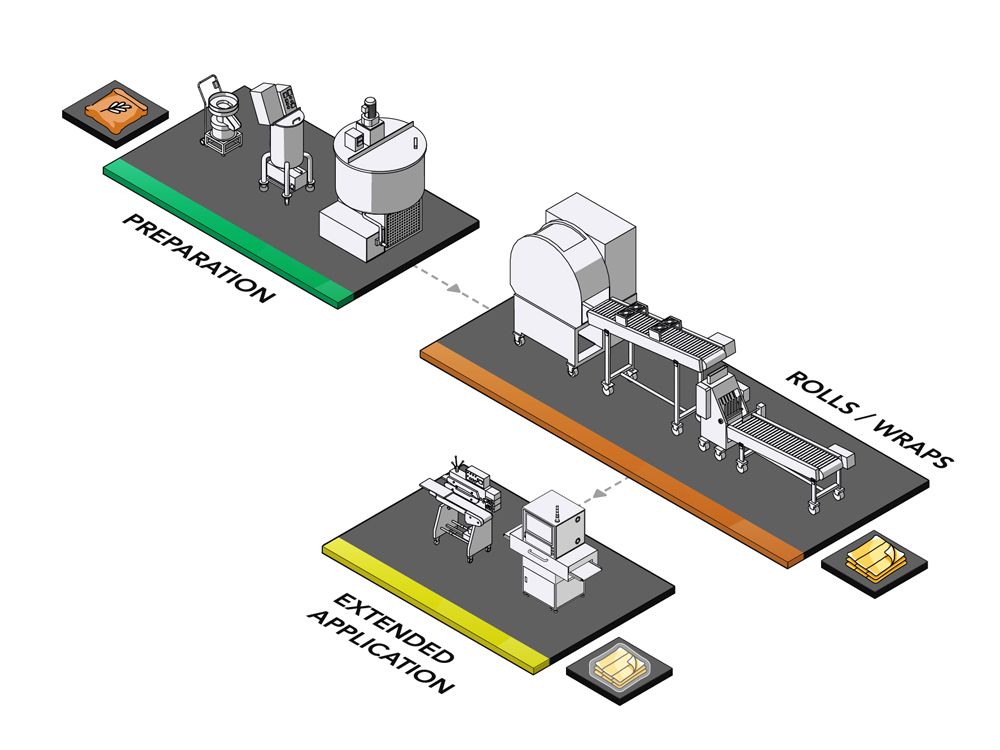

ANKO’s Integrated Samosa Wrapper Production Solution: Preferred choice for large production demands

ANKO did

In this case, ANKO’s SRP Double Line Automatic Samosa Pastry Sheet Machine has twice the production capacity of the single line machine, which is suitable for manufacturers that have demands for large commercial production quantities. ANKO’s integrated Samosa Pastry Sheet Production Solutions include the configuration of various food preparation and processing equipment to increase the production capacity.

ANKO can help you more

ANKO can also provide professional food grade X-Ray inspection machines to increase food safety standards by detecting unwanted foreign objects with real-time access and precision in food safety management.

If you are interested in more information, please click Learn More or fill out the inquiry form below.

- Machines

-

SRP Series Automatic Spring Roll and Samosa Pastry Sheet Machine

After pouring prepared batter into the hopper, the first production process is to bake batter by the baking drum designed by ANKO's R&D team and then a pastry belt is conveyed to go through cooling fans. Continuously, the high-quality copper cutter rotates to cut out 8,100 pieces of samosa pastry in one hour. Moreover, through the change of parts and settings, the length and width of pastry are adjustable.

- Video

- Country

India

India Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in India with advanced automated food production technology for making Layered and Stuffed Paratha, Spring Roll Wrapper, Samosa Pastry, and Rasgulla. We also offer integrated solutions for popular foods such as Samosa, Momo, Dumplings, Chapati, Kachori, Pani Puri, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Samosas are known to have originated in Central Asia, and the name can be traced back to the Persian word “Sanbosag”(triangular pastry), and they were introduced to the Indian Subcontinent by merchants in the 13th and 14th Centuries. Similar foods are found in other countries, such as the Arabian “Sanbusak” or “Sanbusaj,” the Afghani “Sambosa,” Turkish “Samsa,” Iranian “Sambusa,” and “Chamuçq” which is also popular in Goa in India and Portuguese.

Samosas are now one of the most iconic foods in India, they are crowned the “King of Snacks” in Delhi, India, for their gastronomic significance and culinary ingenuity. The most famous may be “Aloo Samosa” which is filled with a spiced potato, and Samosas can also be filled with Paneer, a type of Indian cheese curd. Keema Samosa is made with delicious, minced meats and spices making them very popular. Recently, many consumers are more health conscious about their food intake, and therefore producers are making baked Samosas instead of the deep-fried versions. Many healthier ingredients such as whole wheat flour, organic ingredients, whole grains, and tofu are now being incorporated to make great tasting Samosas.- Handmade Recipe

-

Food Ingredient

All Purpose Flour/Maida/Ghee/Oil/Water/Ajwain/Salt

How to make

(1) Add flour, ajwain, a pinch of salt in a bowl. (2) Stir well and add ghee or oil. (3) Use fingers to rub ghee until the mixture becomes breadcrumbs. (4) Add water. (5) Knead them into dough with hands. (6) Cover with a wet cloth and set aside to rest for 30 minutes. (7) Cut the dough in half. (8) Roll out each dough into 3 cm thick round pastry. (9) Apply a round pastry cutter to cut out small round pastries. (10) Roll out each small piece of pastry into 0.5 mm thick. (11) Cut it in half. (12) Use a brush to smear water on the straight edge. (13) Roll into a cone shape and seal the seam for filling.

- Downloads

English

English