Cheese Spring Roll Automatic Equipment Designed with a Customized Filling Mold

The company's cheese roll features its thin pastry made of batter. Compare to Chinese spring roll, they are quite similar in the handmade production and crispy taste. This cooperation is not the first time. The client had bought our other machine types and was satisfied with their quality and productivity. This time, through our customized services and trials, we followed his recipe and successively produced cheese rolls via our cheese spring roll production line. Therefore, he still purchased our machine without hesitation to meet growing demands. (The SR-24 is no longer available. The new model is SR-27 machine.)

Cheese Roll

ANKO Team Research Problem Solving or Solution Delivery

In order to tailor to the client's requirement, we customized a filling mold.

The client requested that the final product should be within 30 g that was 10 g less than the standard size (40 g). Firstly, ANKO engineer downsized pastry and decreased an amount of filling for each cheese roll. However, an unchanged filling mold with a less amount of filling resulted in a loose lump of cheese and the instability of depositing position. Therefore, we customized...(Please contact us to get more information)

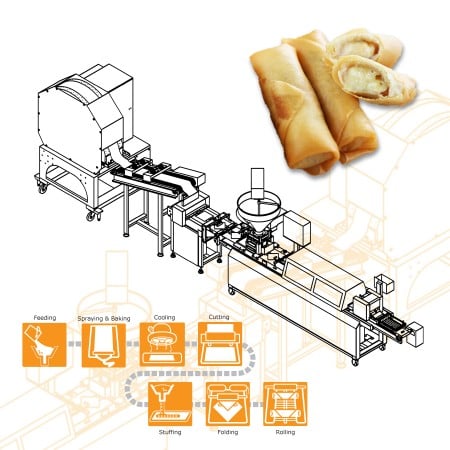

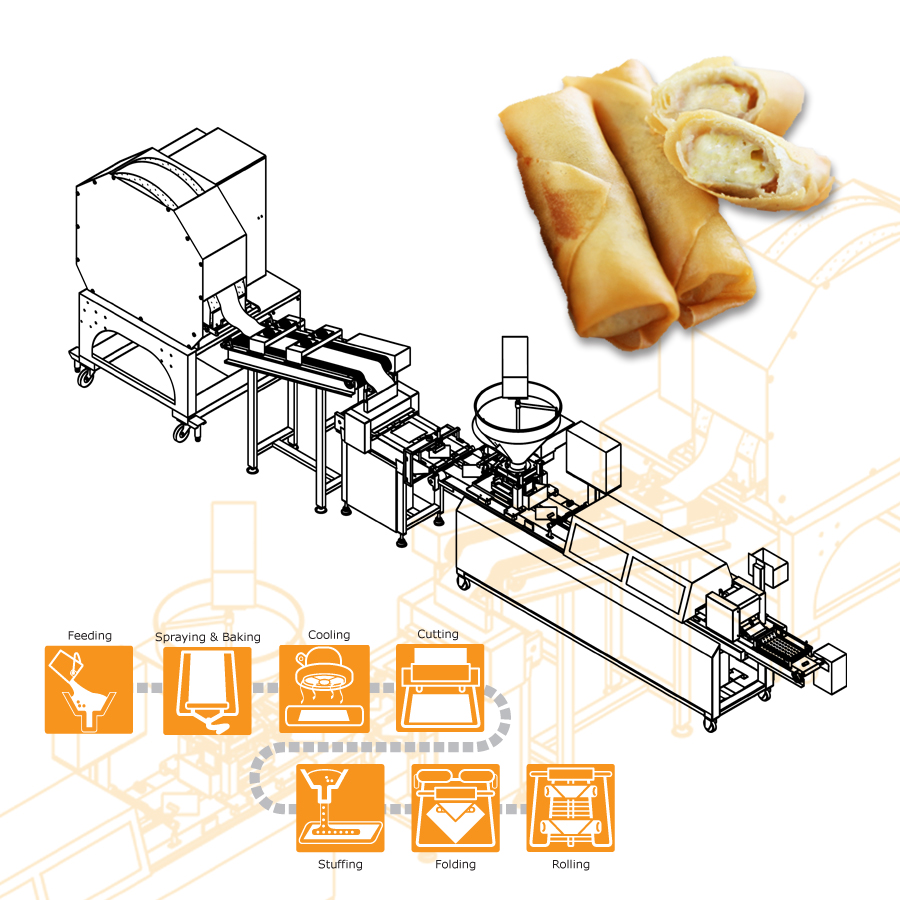

Food Equipment Introduction

- Pour cheese filling into filling hopper

- Pour well-stirred batter into batter tank.

- Adjust settings on the control panel and make sure the temperature and condition of baking drum.

- Bake batter into a belt of pastry.

- Cool them by fans.

- Cut into 190 mm square pastry

- Turn cut pastry in position, ready to be fed with cheese.

- Feed filling: locate cheese on a set place.

- Fold pastry: fold the first corner to the center to cover the filling, and then seal the filling by left and right side flappers.

- Apply glue: apply batter on the last corner as glue.

- Roll up: roll up toward the last corner, at the same time, seal the end.

The patented design of pastry tuning device minimize the required space for the machine production.

If you saw the process of rolling up spring roll, you would know that turning a corner of pastry toward yourself is smoother to roll it up. Then, how should we do to imitate the hand gesture? In the past, we would place two conveyors in different directions to cause a turn, but the installation occupied too much space. Also, the speed and height differences might lower yields. Therefore, thinking in reverse, ANKO designed a new lifting and turning device. Use the vertical space to lift pastry, clip and turn it, then put it down. That largely saves the machine required space and increases yields. We also successively have got a Taiwan patent on the device, No. M457429.

- Solution Proposal

Premium Design of an Automatic Spring Roll Machine for Enhanced Production

ANKO did

Not only can ANKO's Spring Roll Machine produce standardized Spring Roll products, but it can also create customized ones. It is capable of processing a wide variety of filling ingredients, such as vegetables, meats, mixed veggies with meats, or even sweet ingredients like cheese, chocolate with banana, apple with cinnamon, and more. ANKO's Spring Roll Machine only requires three simple steps to initiate production, significantly reducing training costs.

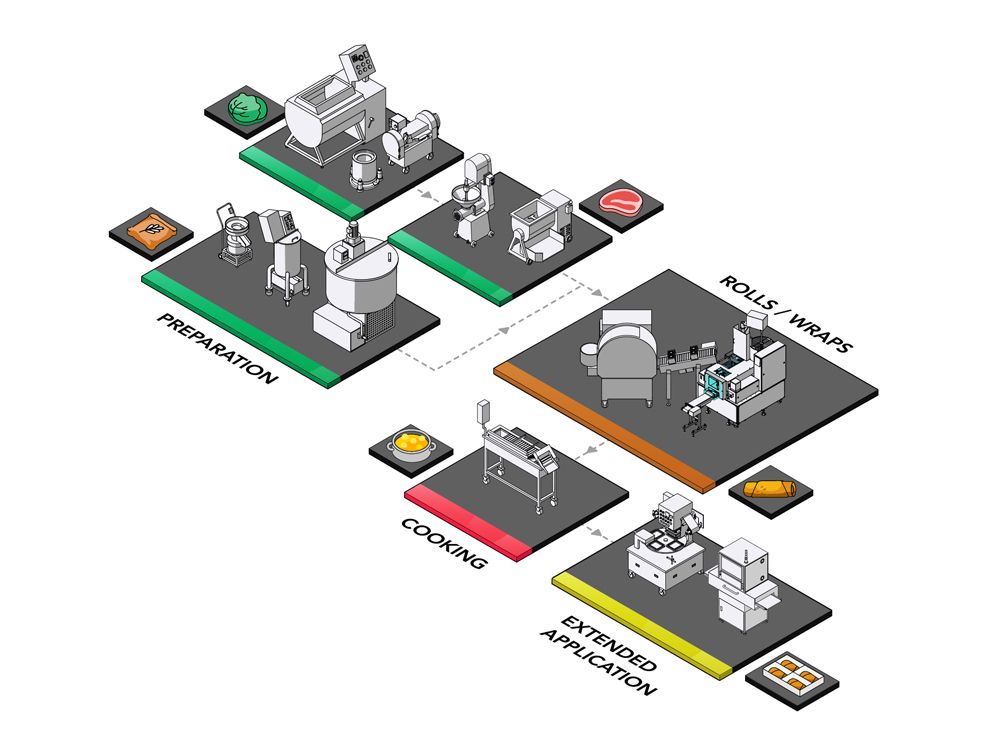

ANKO can help you more

In addition to the Spring Roll Machine, ANKO can also configure a One-stop Spring Roll Production Solution, which includes the dough mixer, vegetable cutter, meat grinder, rolling and forming, fryer, packaging, and food inspection machines, enabling high-volume manufacturing. Our experts offer product performance evaluation based on product specifications, desired tastes, textures, and appearances, and then propose implementation solutions.

For more information, please click Learn More or complete the form below and we will get back to you as soon as possible.

- Machines

-

SR-24

Well-stirred batter is spread on a big baking drum to be baked into cheese roll pastry, its thickness is adjustable and hardness is controlled by the baking drum temperature. A belt of hot pastry is cooled down immediately and cut out pieces of pastry. They are continuously conveyed to a depositor.

Then, it is the time to pour prepared cheese into filling hopper. Due to the fact that cheese must be kept at a certain temperature, we installed a customized hopper with double layer, the outside layer is connected to a cooling machine to keep cheese at 4℃ constantly.

Not only can the thickness and hardness of cheese roll be changed, but its weight is also adjustable. The ease change of parts enables the machine to produce products with different weights. Afterwards, the filling will be exactly deposited via a sensor detection system. For wrapping up, a folding device folds three corners of pastry, a dropping device drips batter as glue, finally, a stainless steel net is used for rolling up cheese rolls. 2,400 rolls can be manufactured in one hour. (The SR-24 is no longer available. The new model is SR-27 machine.)

- Video

- Country

Lebanon

Lebanon Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Lebanon with advanced automated food production technology for making Cheese Spring Rolls, Samosas and Kibbehs. We also offer integrated solutions for popular foods such as Maamoul, Sambouseks, Dumplings, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

The most common recipe for cheese roll is to put cheese, ham, sweet corn, onion on a slice of flattered bread, roll up, coat with breadcrumbs, and then deep fry it. Due to the convenience of its preparation and preservation, this dish is very popular at a party and family gathering or as a snack when children come home after school. In this case, the cheese roll pastry is made of batter and deep fried to create a crispy taste. Ketchup and chili sauce are typical dips.

- Handmade Recipe

-

Food Ingredient

All Purpose Flour/Oil/Water/Salt/Cheese

How to make

(1) Add all purpose flour, oil, salt in a bowl. (2) Add water and knead them into pliable and smooth dough. (3) Cut into equal portions of dough balls. (4) Roll out each dough ball. (5) Put a chunk of cheese on pastry close to an edge. (6) Wrap up cheese from the edge to a half. (7) Fold the left and right sides toward center. (8) Smear water on the opposite edge. (9) Keep rolling up and stick the ends. (10) Deep fry until golden brown.

- Downloads

English

English