ANKO’s SR-24 Spring Roll Production Line is highly efficient and cost effective for North American markets

The client already has a spring roll processing machine from other company. Since his business grew, he would like to increase productivity and improve the looks of products. He had been looking for a better solution, also an acceptable price. Finally, ANKO gained favor with the client. It's not only because the machine itself, but our competent team. We have abundant knowledge in food ingredients and recipes; We have years of experience to determine the effect of any conditions, such as temperature, water temperature, pneumatic equipment, or electrical equipment on machinery and food; and last but not least, our engineers are full of passion to find every possible solution. (The SR-24 is no longer available. The new model is SR-27 machine.)

Lumpia, Spring roll

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. How to solve the stuffing was too loose to be rolled up firmly?

Stuffing ingredients usually contain fat which solidifies at a low temperature to bind other ingredients. As depositing, the stuffing is still in a rectangular shape.

In this case, the client sometime used frozen stuffing and sometime used unfrozen stuffing. The machine setting should be adjusted to suit different conditions. However, the client didn't notice the point, causing the problem that mentioned above. Therefore, using frozen stuffing only and setting corresponding parameters were the solutions to resume the smooth production.

As our engineer was solving the problem of loose stuffing, he noticed that the wrapping action seemed delay. He checked and found that there was a...(Please contact us to get more information)

Solution 2. How to revise the appearance of Spring Rolls?

The client asked us to improve the look of his spring rolls. Their both ends protruded. The solution A is to modify his machine, designing a device to press both ends inwards. The solution B is to...(Please contact us to get more information)

Ingredients are tucked in well and Spring Rolls are formed without protruding which meet client’s requirements

Solution 3. How to adjust the Spring Roll recipe for easier wrapping?

The client's spring roll pastry contained too much oil. That became too hard to wrap after baking. The batter recipe made by the client included more oil than the standard recipe made by ANKO. The former batter was too hard to wrap up stuffing. In order to maintain the elasticity, we lowered the temperature of baking drum. However, the pastry became too soft to scrape from the baking drum. Finally, our engineer adjusted the recipe...(Please contact us to get more information)

ANKO’s engineers continue to improve the production process to ensure Spring Rolls are formed smoothly. There only needs to be one person responsible for collecting the Spring Rolls to be placed on sheets and then frozen.

Food Equipment Introduction

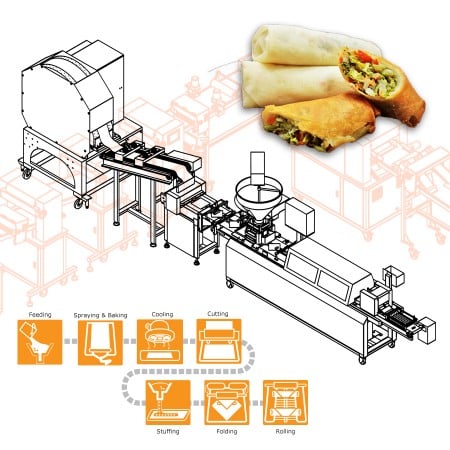

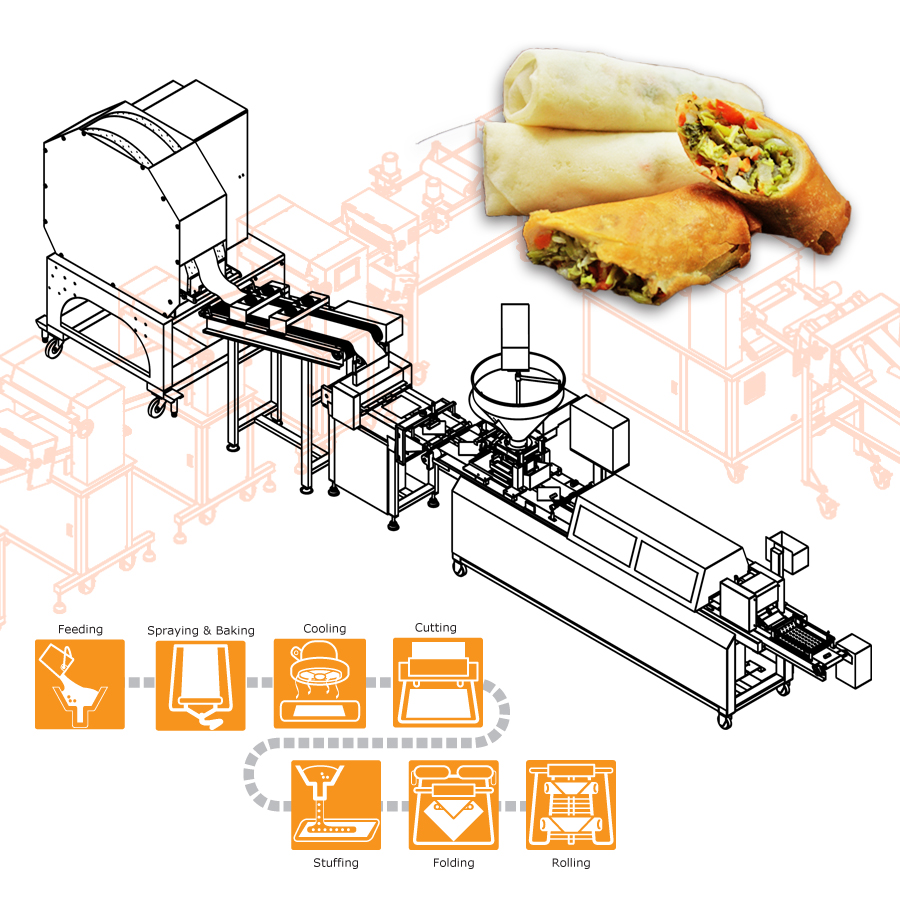

- Pour cooked stuffing into hopper.

- Pour mixed batter into batter tank.

- Set temperature

- Bake pastry belt

- Cool pastry belt under fans

- Cut pastry belt into 200mm*200mm squares.

- Turn cut pastry in position, ready to be fed with stuffing.

- Feed stuffing: locate stuffing on a set place.

- Fold pastry: fold the first corner to the center to cover the stuffing, and then seal the stuffing by left and right side flappers.

- Roll up: roll up toward the last corner under rolling net, at the same time, seal the end.

The spring roll production line is designed for product standardization

The design of fans is to shorten the cooling time, standardize products and make production efficient, so we launched a series of test to properly set the wind speed and running time according to dough ingredients.

In the manual production process, the pastry and stuffing are often prepared separately. As the pastries cool down, they are packed and sealed off to avoid moisture until the stuffing is ready.

On one hand, the cooling time is hard to control. If the cooling time is too long, spring roll pasties absorb moisture that causes them to stick together and ruins the relish of spring roll. On the other hand, whether pastries are suitable for wrapping needs years of experience and a touch to determine. Therefore, having the fans, not only can the taste be maintained, but it is also unnecessary to check every piece by experiences.

- Solution Proposal

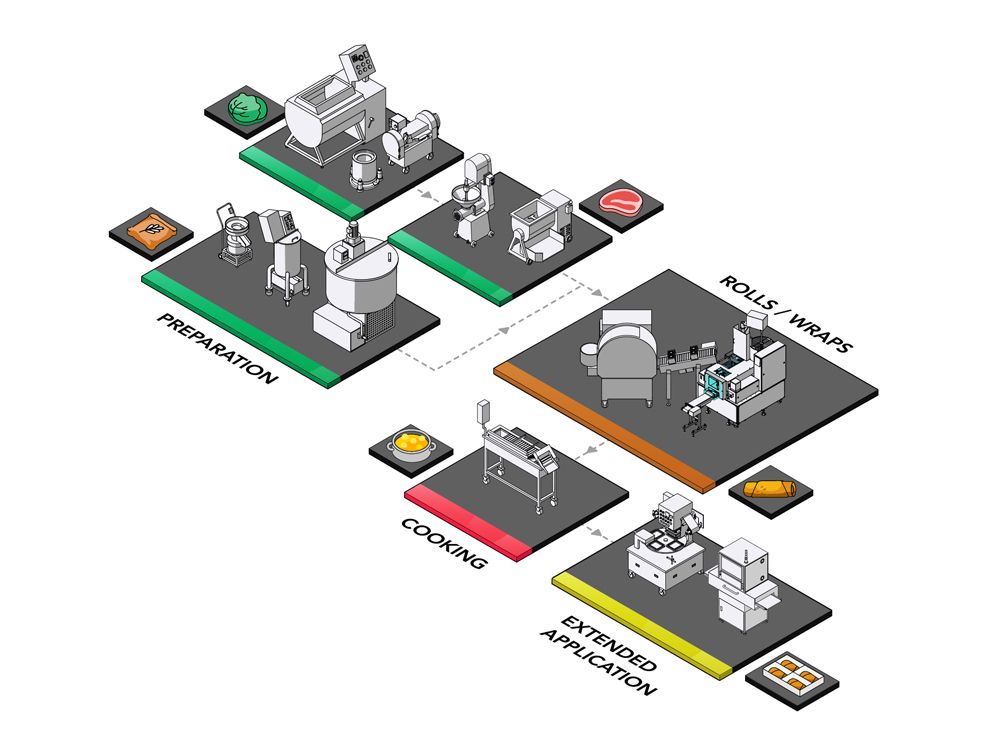

Fully Automatic Spring Roll Production Solution to Assist You with High Volume Manufacturing

ANKO did

ANKO’s SR-27 Automated Spring Roll Production Line has the capacity to produce 2,700 pieces per hour, allowing a company to fulfill large orders, especially suitable for large food factories, central kitchens, and large-scale manufacturers. It only requires one employee to operate the production line thus reducing labor, management, and training costs.

ANKO can help you more

According to market research, there is a rising demand for Spring Rolls worldwide. To meet the huge market demand for Spring Rolls, companies will greatly benefit from using ANKO’s Automatic Spring Roll Production Line. Our professional consultant will provide Premium Spring Roll Production Solutions depending on your requirements. In order to sell Spring Rolls in retail or wholesale channels, ANKO can also offer a Food Packaging Machine and Food X-Ray Inspection Machine to increase food safety and quality.

For more information on ANKO's Spring Roll Production Solution, please click Learn More or complete the form below.

- Machines

-

SR-24

The batter for making spring roll pastry is prepared and we usually suggest putting it overnight. At the beginning of production, the nozzle evenly sprays batter onto baking drum. Through parameter settings for thickness and temperature, the texture and hardness/softness are adjustable. Then, it is cooled by fans while batter is baked into pastry belt.

After cooling, the cutter cuts the belt into square pieces. The prepared stuffing is in the stuffing hopper and ready to be deposited on pastries. The sensor detects the pastry's position and signal the depositor to lay down stuffing at the right time.

Finally, the forming unit folds three corner of the pastry and the last corner is exactly dotted with batter as glue. Through the stainless steel net, a spring roll is rolled up and completely formed. With the fully automatic production process, 2400 rolls can be made in one hour. (The SR-24 is no longer available. The new model is SR-27 machine.)

- Video

Baking pastry, depositing stuffing, rolling up pastry, and other processes are all in one production line. SR-24 Spring Roll Machine is fully automatic to produce 2,400 spring rolls in one hour. Also, various stuffing recipes are ready to diversify your product lines. With an SR-24, you are the chef of borderless cuisines.

- Country

United States

United States Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in United States with advanced automated food production technology for making Dumplings, Egg Rolls, Empanadas, Spring Rolls, Burritos, Mochi, Quesadillas, and Spring Roll Wrappers. We also offer integrated solutions for popular foods such as Samosas, Momo, Pierogi, Tortillas, Shumai, Tapioca Pearls, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Chinese cuisine develops broad and profound. In the age of globalization, foods spread to other countries usually fuse local cultures and become distinctive tastes. Spring roll is a typical example; a sheet of thin and square pastry wraps up local ingredients, and then the roll is deep fried to make it crispy. Afterwards, due to the popularity of fast food, this kind of deep-fried food is a choice for quick cooking and serving in any occasion. The client produces traditional meat and vegetable flavor, in addition, special shrimp stuffing. Attached with his unique, special sweet and sour sauce which the client is proud is unforgettable taste to gourmets.

- Handmade Recipe

-

Food Ingredient

For pastry-All Purpose Flour/Water/Salt/Oil, For filling-Ground Beef/Glass Noodles/Carrot/Ginger/Scallions/Soy Sauce

Making the pastry

(1) Mix and stir flour, water, salt, and oil together (2) Heat a frying pan (3) Apply a brush to smear a thin layer of mixture in the pan (4) As the edges of the pastry slightly peel off, flip it over to cook the other side for a few seconds

Making the filling

(1) Soak glass noodles in water for 10 minutes (2) Drain and rinse with iced water (3) Roughly cut glass noodles (4) Chop carrot, scallions, and ginger (5) Mix ground beef, chopped carrot, scallion, and ginger together (6) Scoop beef mixture and place it on a spring roll pastry. It is better to place it close to the edge (7) To roll up the spring roll starts from the side with filling (8) Roll half the pastry and then fold the left and the right sides toward the center (9) Then, roll the pastry to the end (10) Deep fry spring rolls and enjoy them with sauce

- Downloads

English

English