ANKO Automatic Shumai Machine Reduces Labor Costs for a Mauritian Company

The client has a central kitchen to produce and sell shumai to retailers and takeaways. The growing demand and labor costs prompted him to find an automation solution. Through his friend's introduction, he knew that ANKO is a professional food machine manufacturer. When he visited us for machine test, we used radish shreds in substitution for cassava shreds because cassava is not common in Taiwan. It's also an unprecedented attempt for us. Finally, we were glad to succeed in producing radish shumai by our shumai machine and earned recognition from the client.

Shumai

ANKO Team Research Problem Solving or Solution Delivery

No fat in radish shreds shumai leads to unsmooth extrusion.

The design of shumai machine was based on the production of popular vegetable and meat mixture shumai. The meat fat functions as lubricant in the process. ANKO team replaced cassava shreds with radish shreds and tapioca to test. It turns out that dry filling impeded machine extrusion. After discussion with the client, ...(Please contact us to get more information)

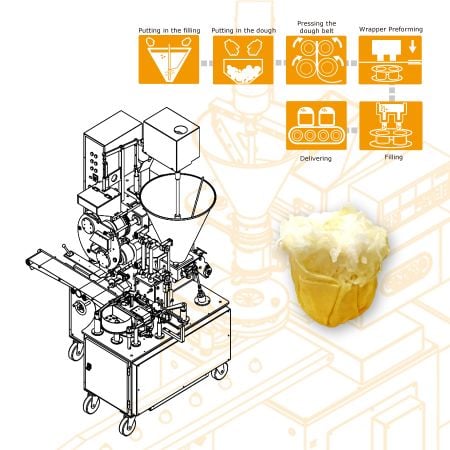

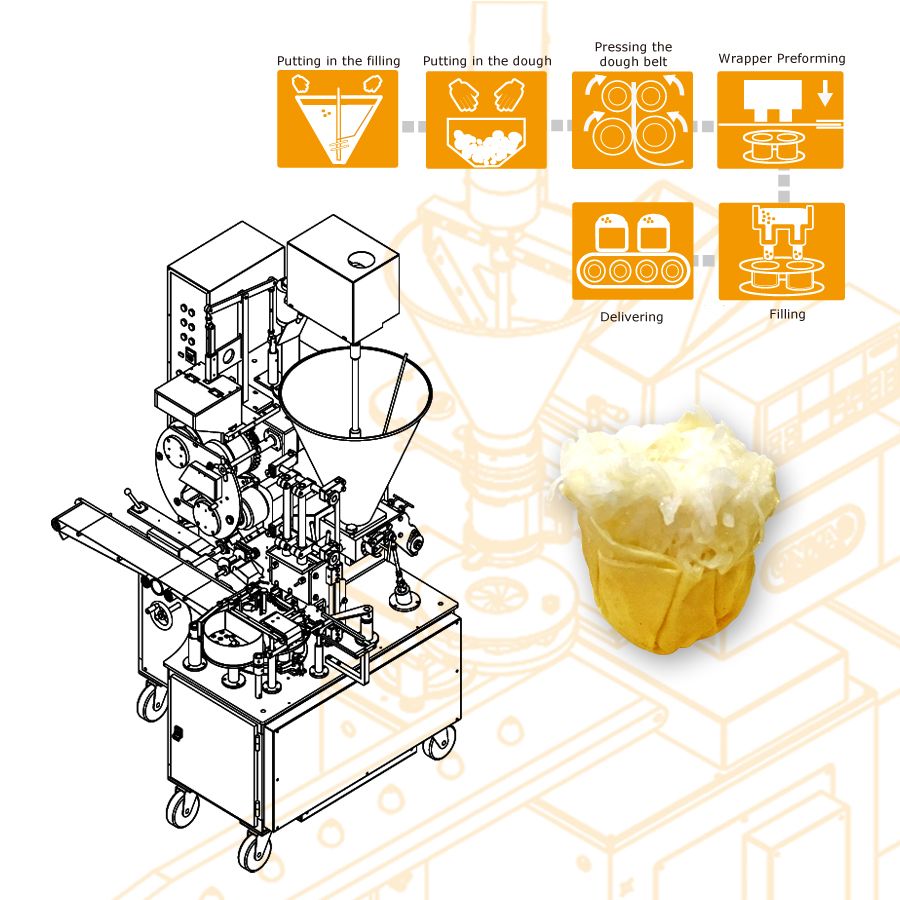

Food Equipment Introduction

- Stir flour into fluffy particles, and then pour into dough hopper.

- Cut out radish into 2 mm thick shreds.

- After draining radish shreds, add them and tapioca into a mixer. Pour well-mixed filling into filling hopper.

- Start the automatic production.

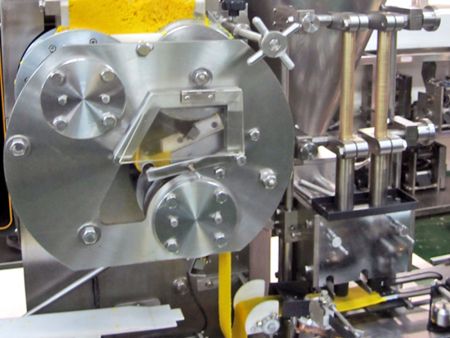

- Press fluffy dough into a dough belt.

- Tong and cut dough belt into wrappers (60-70 mm) as required.

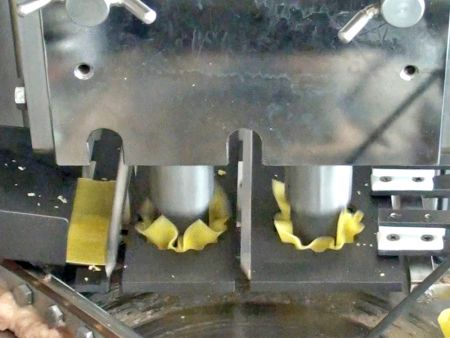

- Punch wrappers into cylinder molds.

- Extrude filling in wrappers

- Clip the top of cylinder to pleat around wrappers and wrap filling tightly.

- Push shumai onto conveyor.

The secret to manufacturing shumai like handmade.

Dough for making shumai wrappers contains less water and high gluten. These dough characteristics affect the possibility of dough belt breakage. Unlike other shumai machines, ANKO's shumai machine can be modified to press different thickness of dough belt. Moreover, how the extruder works with different production rates of dough belt is also influenced by many factors. Any neglect may ruin everything, which is the distinction between machine and human. Therefore, the innovative design of sensor can detect the position of dough wrapper for flexible adjustment to imitate humanlike sensitivity and create high efficiency.

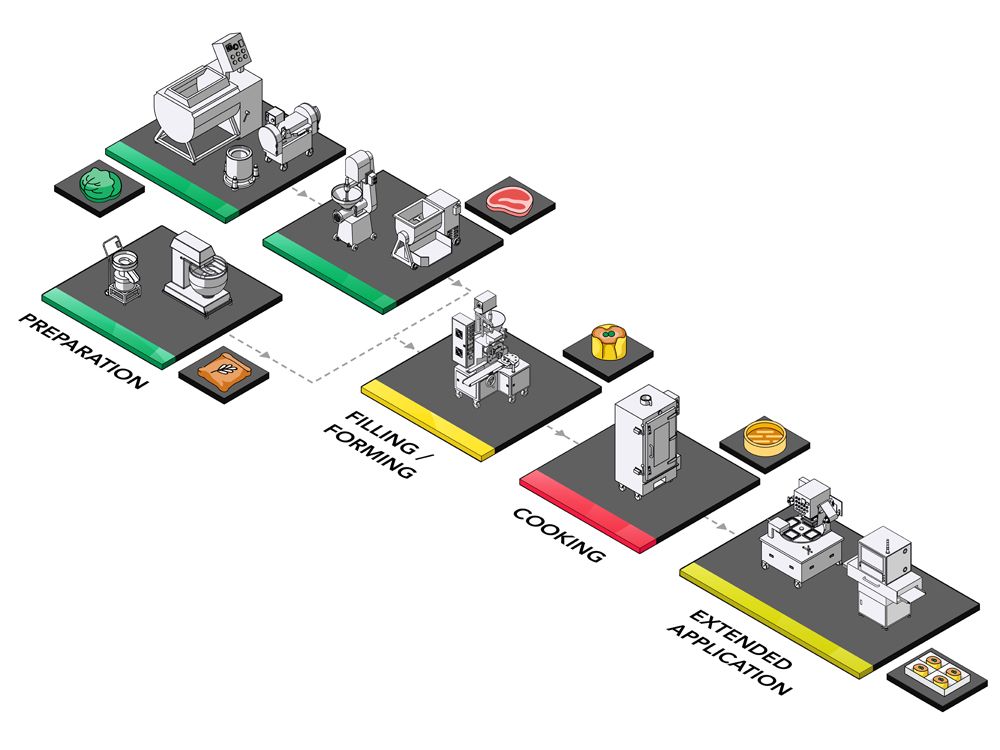

Processing Line Planning

- Sieving

- Mixing

- Vegetable Cleaning

- Vegetable Cutting

- Extracting

- Meat Mincing

- Seasoning

- Forming

- Steaming

- Sealing

- Solution Proposal

ANKO's Food Lab Generates New Business Opportunities with Automatic Shumai Machine by Utilizing New Ingredients!

In addition to radish shreds Shumai, ANKO has also tried various ingredients such as soy-based meat, sticky rice, shrimp, mixed vegetables, and more to create high-quality Shumai. With a collection of over 700 classic recipes from around the world, ANKO has successfully developed new food products for our clients. Our professional assistance and services encompass recipe optimization, production automation, problem-solving, new product research and development, and more, all of which can greatly benefit your food business.

ANKO not only offers the HSM-600 Automatic Shumai Machine but also the HSM-900 Triple Line Shumai Machine, capable of producing up to 9,000 pieces per hour. We provide comprehensive one-stop services tailored to your requirements, including front-end to back-end equipment configuration, turnkey project planning, machine trials, installation, and training.

If you’re interested in more information, please click Learn More or feel free to fill out the form below, and we will get back to you as soon as possible.

- Machines

-

ACD-800

The multipurpose vegetable cutting machine can be equipped with different blades according to individual requirement. Having one machine can deliver different types of cuts, including shredding, dicing, and slicing. The length of final products is also adjustable through the customized adjustment. In this case, the machine is utilized to cut radish into 2 mm thick and 7 cm long shreds. The minimum capacity is 200 kg of vegetables which can be processed within one hour. In short, ACD-800 is an efficient and multipurpose cutting machine.

HSM-600

The user only has to stir the wheat flour into fluffy dough and pour dough and stuffing into hoppers before turning on HSM-600 Automatic Double Line Shumai Machine. One machine can complete dough pressing, cutting, stuffing extruding, and shumai forming. The finished products are lined up on conveyor for the next packing, freezing, or cooking, which benefits the client's central kitchen business. Not only radish shreds we used for test, but also chicken, fish, beef, pork, shrimp paste, fish paste, etc. are able to be extruded by the machine extruder. HSM-600 can also be customized to produce extra large Shumai (Dim Sim) that are 80g per piece.

Additionally, the Internet of Things (IoT) system has been introduced to the HSM-600 machine to provide access to remote monitoring via mobile devices. This reduces labor on the line, and provides real-time production information to monitor your production output. The System is also programmed to identify necessary part replacements, and automatically provides maintenance reminders that increases efficiency, and lowers overall production and maintenance costs.

- Video

- Country

Mauritius

Mauritius Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Mauritius with advanced automated food production technology for making Shumai, Samosas and Dumplings. We also offer integrated solutions for popular foods such as Stuffed Balls, Roti, Puri, Momo, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

One of iconic dishes in Cantonese dim sum culture is shumai. That is usually made of pork and wrapped up with a dough wrap, shaped into a top open cylinder and garnished with a pea or crab roe. Some people replace dough wraps with dried seaweed to make seaweed shumai. The client living in Mauritius is a Mauritian of Chinese origin. He would like to make the typical dim sum not with pork but with cassava which is easy to get in local. Unlike pork shumai, cassava shumai is non-greasy and has a taste of cassava fiber, making a refreshing change.

- Handmade Recipe

-

Food Ingredient

For wrapper-All Purpose Flour/Salt/Water, For filling-Tapioca/Cassava

Making the wrapper

(1) Mix all purpose flour, salt, water in a large bowl. (2) Knead them into a chunk of elastic and smooth dough. (3) Cover with a wet cloth and rest for 1-2 hours. (4) Roll the dough into cylinder by hand. (5) Equally portion out the dough. (6) Apply a rolling pin to roll out each dough balls. (7) Cut out square shumai wrappers.

Making the filling

(1) Shred cassava into 2 mm strips. (2) Drain cassava shreds. (3) Mix cassava shreds and tapioca together.

How to make

(1) Put a scoop of filling on a wrapper. (2) Squeeze the wrapper around to form it into cylinder and leave the top open. (3) Steam shumai for about 5-10 minutes.

- Downloads

English

English