ANKO transforms a Malaysian client’s ideas into new Siew Mai products

The client runs a vegetarian food processing factory with HACCP as well as Halal certification. Hundreds of vegetarian food products are manufactured by the company and exported to Singapore, Australia, and other countries. With the new online shopping site, they received more orders than before, so that they planned to replace high-cost and low-efficient handmade production with automation. The client has ANKO's Automatic Spring Roll and Samosa Pastry Sheet Machine already that has been smooth without lagging, as a result, they trust in our machine quality. In this case, the client would like to produce two kinds of siew mai with one machine. One is dough wrapper; the other one is tofu skin. Both they and we wondered whether the innovation of tofu skin siew mai could be made by the same machine. The client would like to have a try because we are the only company who offers testing service.

Siew Mai (Shumai)

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Can Automatic Siew Mai Machine produce Siew Mai using Tofu Skin?

With the same machine, the client would like to create new flavor siew mai wrapped with tofu skin. Ideally, it might be possible. However, trying to make it by hand, we found the texture of tofu skin was not as viscous as dough to stick to stuffing. Our engineer continued adjusting ingredients to increase stickiness but failed. In addition to the first problem, if we assumed that we solved the above problem, the siew mai machine still could not realize the creative idea. The reason was that piles of rectangular tofu skins could not be delivered by machine units, which only work on belt-shaped wrapper. It was inefficient to manually cut and then connect each sheet of tofu skin into a belt prior to manufacture. Also, customizing this kind of machine was out of their budget. In view of the mentioned reasons, the client decided not to produce tofu skin siew mai in the end.

Despite the fact that the project failed, we embodied the spirit of customization. Relying on our professional machine design and years of experience, we try our best to achieve a variety of ideas. Boldly hypothesizing brings up innovation while ANKO proves it conscientiously and carefully. We keep a balance between ideal and reality to offer clients practical suggestions.

Solution 2. How to prevent tall Siew Mai’s wrapper from breaking during the automated production process?

The client desired to produce tall Siew Mai, but the specifications exceeded ANKO’s standardized forming molds. When tall Siew Mai were formed, they tended to tilt on the conveyor belt, however, this was fine with the client. Additionally, the client’s original recipe for their dough wrapper was slightly dry and did not have adequate elasticity. ANKO’s engineers communicated with the client and worked to customize and improve their automated production processes... (Contact ANKO for more information.)

Vegan and plant-based diets have become a mainstream trend. ANKO’s HSM-600 Automatic Siew Mai Machine can process various vegetable and plant-based ingredients. In this case, these Siew Mai are made with a soy-based meat filling. This machine can also process shredded radishes, mixed vegetables, and sticky rice as Siew Mai fillings.

Food Equipment Introduction

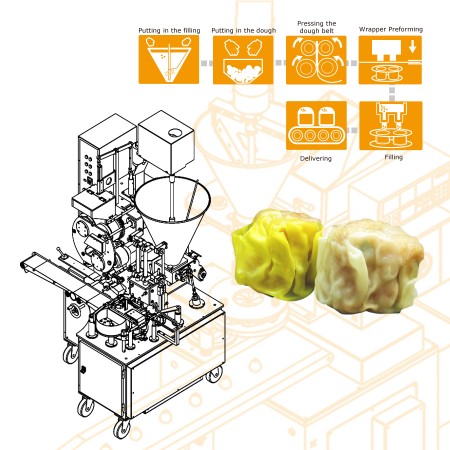

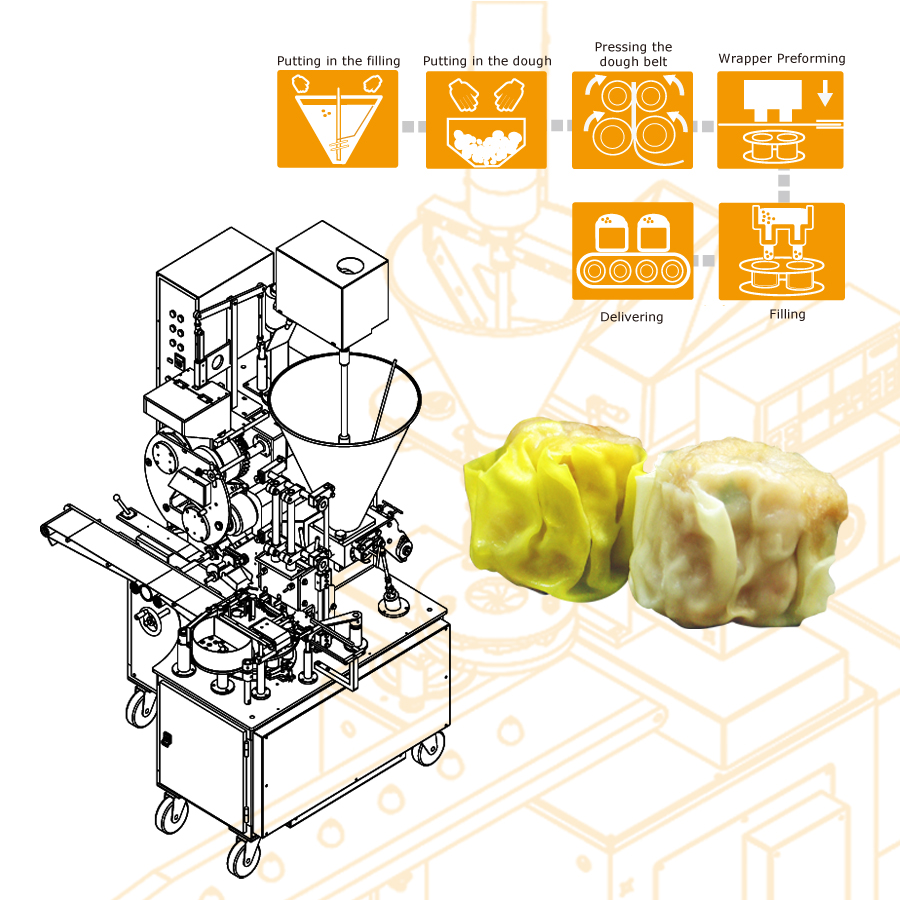

- Stir flour into fluffy lumps and pour them into dough hopper.

- Pour prepared stuffing into stuffing hopper.

- Start automated process.

- Flatten dough.

- Pull and fix dough belt in position with tongs and cut it into desired size (60-70mm).

- Punch wrapper into forming mold.

- Feed stuffing.

- Slightly compact the top of siew mai to pleat on wrapper and make wrapper and stuffing tighter.

- Garnish with chopped carrot.

- Push the finished products onto conveyor.

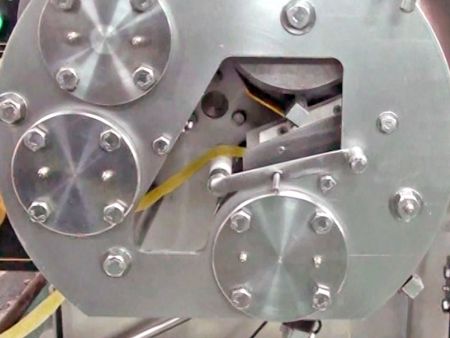

ANKO’s exclusive patented Siew Mai Wrapper Roller design

Multiple components are used in fully automatic machinery to roll and flatten the dough into thin wrappers; during the pressing, rollers may experience slight displacement over time due to normal wear. This can result in uneven thickness of the wrappers. When such a situation occurs, most machines require the time-consuming and labor-intensive process of disassembling and reinstalling components.

If the machine operator is unable to make the adjustments themselves, professional service is required. Therefore, when ANKO designed our HSM-600 Automatic Siew Mai Machine, two sets of pressing rollers were installed with an exclusive dough roller adjustment device. By simply turning the adjustment handle, the thickness of the dough skin can be easily altered. This simple and convenient design allows for timely adjustments and ensures smooth Siew Mai production. ANKO has successfully obtained patents for this design.

- Solution Proposal

ANKO offers Professional Automatic Siew Mai Machine for Mass Production Requirements

ANKO did

The HSM-600 Automatic Siew Mai Machine is the first-generation of being mass-produced with a stable yield. Based on the first-gen mass-production experience, ANKO then developed the HSM-900 Triple Line Siew Mai Machine in 2020. Highly recommended for high volume Siew Mai producers to ensure the stable supply of Siew Mai products.

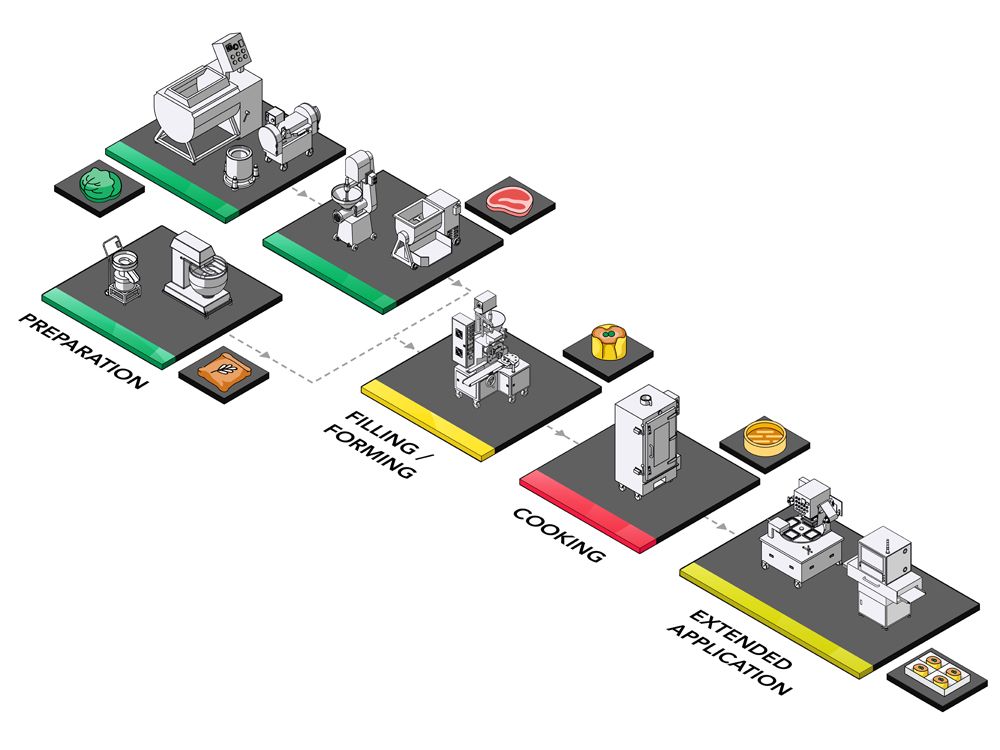

ANKO can help you more

In order to reduce the labor during Siew Mai production, ANKO offers one-stop integrated services for supplying front-end and back-end equipment, such as mixer, vegetable cutter, meat grinder, former, steamer, packaging and x-ray inspection machine. The solutions we provide may vary depending on the actual Siew Mai production requirements.

If you need further information about ANKO's Siew Mai Production Solution, please click Learn More or fill out the inquiry form below.

- Machines

-

HSM-600

ANKO’s HSM-600 Automatic Siew Mai Machine is designed to produce paper-thin wrappers for filling and forming Siew Mai. It only requires the hoppers to be loaded with premade dough and filling ingredients; then, the automated production can reach 5,000 to 6,000 Siew Mai per hour. There are adjustable settings that control the thickness of the Siew Mai wrappers and the size/height ratio of the wrapper and Siew Mai filling. An additional garnishing device can be attached to automatically place green peas, diced carrots, and/or fish roe onto each Siew Mai for the perfect final touch. ANKO can also customize our machine to produce extra-large Siew Mai up to 80g per piece.

Moreover, HSM-600 machine includes a built-in Internet of Things (IoT) system to provide real-time access to data monitoring to manage production better remotely. And having an inventory of spare parts and conducting regular inspections, companies can significantly reduce risks, reduce downtime, and enhance productivity.

- Country

Malaysia

Malaysia Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Malaysia with advanced automated food production technology for making Siew Mai (Shumai) and Kompia. We also offer integrated solutions for popular foods such as Curry Puffs, Dumplings, Bagels, Spring Rolls, Wonton, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Chinese cuisine is deeply rooted in Malaysian food culture and has been introduced by Sino immigrants over the years. Siew Mai is a very popular food item that has evolved to meet the taste of the Malaysian market; unique ingredients such as Crab Roe, Mushrooms, Salted Egg Yolks, and Preserved (Century) Eggs are incorporated with pork to make Siew Mai. Many producers use fish or shrimp to specially make Halal Siew Mai which caters to Islamic consumers; spicy chili, sweet, or tomato-based sauces are served on the side for dipping. Recently, vegetarian, or vegan Siew Mai using Tofu, Sticky Rice, and Plant-based meat alternatives are also trending. These Siew Mai are often garnished with diced carrots, corn kernels, or peas. Frozen Siew Mai was created as a convenient food product that can be purchased in wholesale markets, hyper marts, supermarkets, convenience stores, and online shopping platforms. Numerous Siew Mai recipes can be found on the internet for home cooks to explore this classic Chinese Dim Sum.

- Handmade Recipe

-

Food Ingredient

For wrapper-All Purpose Flour/Wheat Protein/Water, For vegetarian filling-Soy Meat/Oil/Salt/White Pepper

Making the wrapper

(1) Mix all purpose flour and wheat protein in a bowl. (2) Add water and knead the dough until smooth and pliable. (3) Cover with cling wrap and rest for 30 minutes.

Making the filling

(1) Soak soy meat in water and drain. (2) Minced the textured soy protein. (3) Season with oil, salt, and white pepper.

How to make

(1) Take out the dough and roll it as thin as possible. (2) Cut the dough sheet into small pieces, circle or square. (3) Scoop a spoon of filling on a wrapper. (4) Then, wrap the filling and shape siew mai into cylinder, but leave the top open. (5) Steam siew mai for 10-15 minutes.

- Downloads

English

English