ANKO developed an Automated Mochi Production Solution for a U.S. client to accomplish their takeout business expansion

An ANKO client operates a restaurant in Los Angeles serving authentic Asian specialty foods, and Mochi is one of their best-selling desserts. Many diners enjoy ending their meals with an order of Mochi, often paired with tea or coffee. Our client wanted to increase their revenue by making their popular Mochi available for takeout, but they didn’t have enough labor to accomplish this plan. While searching for automated food machine options, this client discovered ANKO Food Tech and scheduled a machine trial. ANKO recommended using the SD-97W Automatic Encrusting and Forming machine to the client for making Mochi and Mochi Ice Cream. The client was very impressed with the machine demonstration, and the taste of the final products. Based on their volume, they decided to purchase the SD-97SS Table-Type model. After delivering the machine, our team helped the client to familiarize themselves with the production process, machine maintenance routines, and overall operations.

Mochi / Mochi Ice Cream

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. ANKO's created a professional automated Mochi production solution, including the perfect recipes for great quality and tasting Mochis

A client’s two best-selling Mochi products are the Pandan Flavored Mochi filled with Peanut filling, and a Taro Mochi made with a Red Beetroot juice to add color to the Mochi. They approached ANKO to help with the transition to automated Mochi production and address labor shortage issues. The client visited ANKO Food Tech in Los Angeles, where they conducted a demonstration production run with their own premade Mochi dough and fillings, and found the peanut filling was too hard for the filling system, resulting in inconsistent products with exposed filling. To resolve this problem, our engineers discovered how their filling was made and offered some adjustments that solved the issue…..(Contact ANKO for detailed information)

As a result, ANKO resolved the Mochi forming issues, and helped the client create Mochi with a perfect filling ratio. The final weighed 38 grams each, meeting all the client’s production requirements, and the texture was also perfectly soft and chewy.

Solution 2. Strategic Market Innovation - ANKO Consultants developed “Mochi Ice Cream” for the client as a New Product

A client’s restaurant is located near a tourist attraction, and they are busy during lunch and dinner hours and even for afternoon tea. Based on the client’s business operations, ANKO suggested the client create multiple production lines, and add ”Mochi Ice Cream” to their menu specifically for young consumers. Our engineers used the ANKO SD-97W Automatic Encrusting and Forming Machine to produce Mango flavored and Taro flavored Mochi Ice Creams at a rate of 1,500 pieces per hour. Once finished, the products are dusted with starch, boxed and placed in the freezer, ready to be served.

Food Equipment Introduction

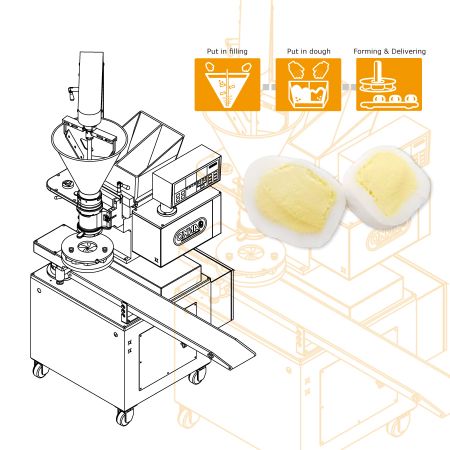

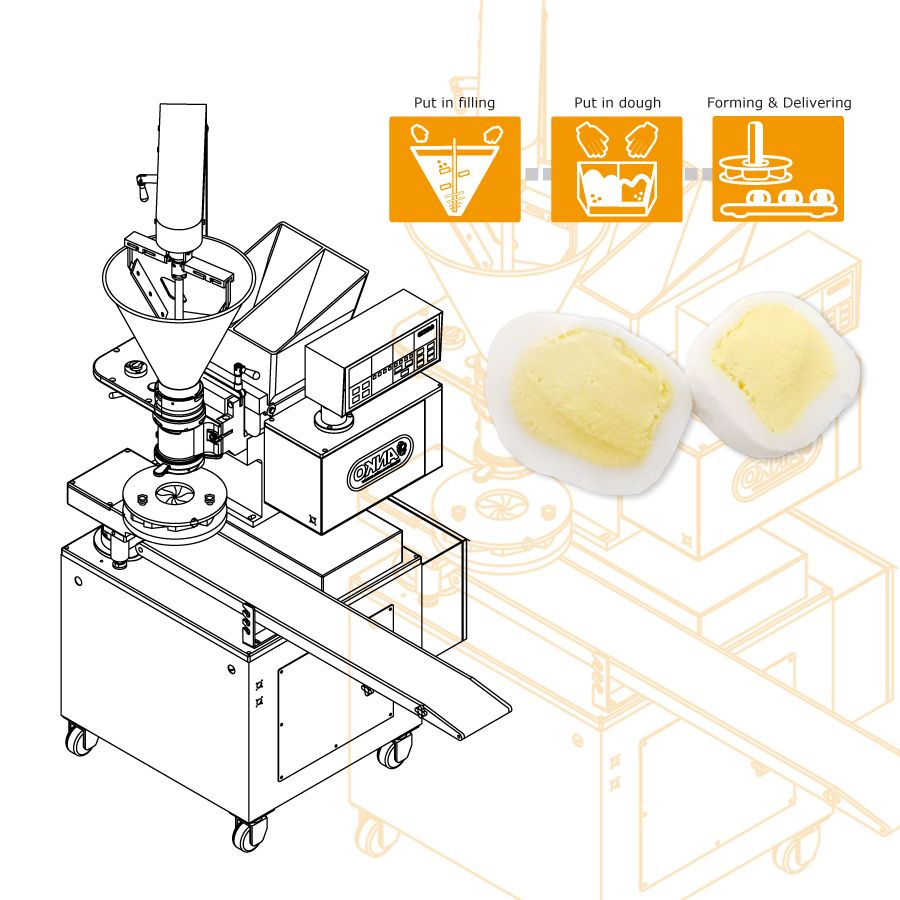

- Load the dough hopper with Glutinous rice dough

- Place filling ingredients in the filling hopper

- Mochis made with SD-97W forming molds

Meeting the Vast Market Demands with a Variety of Authentic Food Products

The ANKO SD-97 Series Automatic Encrusting and Forming Machines are easy to assemble and clean, and they are also compact suitable for Independent and small food businesses. This model uses straight motors with high torques, thus they can produce a wide range of products. The dough processing system and dough screw are made of durable stainless steel, to be able to process different types of dough, and withstand high-pressure, and high-temperature work environments. The filling system can process a wide range of ingredients such as cheese filling, and fibrous vegetable and meat fillings without altering their original texture. The machine then extrudes the filling onto the center of the product ready to be encrusted. The SD-97 series is designed to produce a wide range of products to increase production versatility and provide strategic advantages for food manufacturing companies.

- Solution Proposal

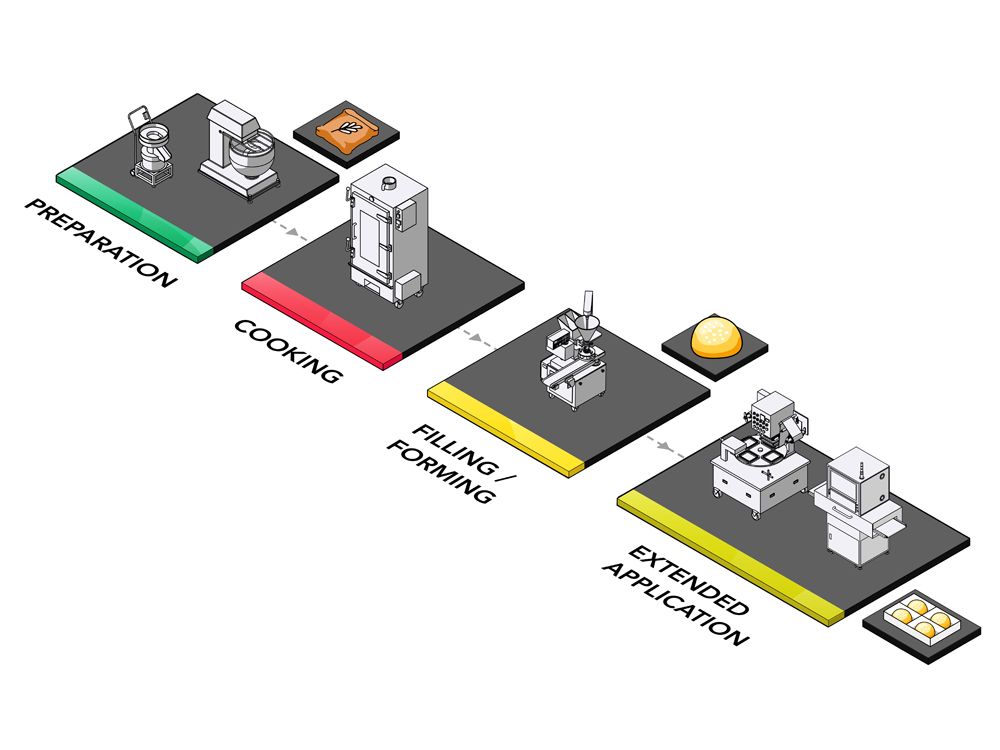

ANKO created a One-stop Mochi Production solution to optimize the production processes

ANKO configured a Mochi Making Machine to meet our client’s individual business production requirements. We also offer one-stop production solutions for medium to large-scale Mochi manufacturers to reduce labor requirements and improve production efficiency. This includes commercial mixers that process premixed flour and water into a paste, and then transfers the paste to a steamer to cook into Mochi. A forming machine then fills and divides each Mochi into the final products, ready to be weighed, packaged, and examined with an X-Ray machine. These automated processes significantly improve product packaging efficiency and quality control. If you are interested in learning more about ANKO machines and production solution services, please click Learn More or fill out the inquiry form below. Our professional consultants can develop a customized production solution just for you.

- Machines

-

SD-97W

The SD-97W Automatic Encrusting and Forming machine can produce a wide range of food products. By changing the forming molds, the machine can produce spherical, oval, rectangular, squared, or teardrop-shaped products; and there are several different types of pleat designs to choose from. The non-patterned spherical molds can be used to form Mochis, as well as Meat Buns, Custard Buns, Sesame Balls, Filled Cookies, Croquettes, Tang Yuan, and much more. All products appear and taste as if they were handmade.

Additionally, the Internet of Things (IoT) system has been introduced to the SD-97W Automatic Encrusting and Forming machine to provide access to remote monitoring via mobile devices. This reduces labor on the line, and provides real-time production information to monitor your production output. The System is also programmed to identify necessary part replacements, and automatically provides maintenance reminders that increases efficiency, and lowers overall production and maintenance costs.

- Video

ANKO SD-97 series Automatic Encrusting and Forming machine can produce Mochi filled with either granule fillings or paste fillings, and it can also produce Mochi Ice Creams. The Mochi and filling ratio can be adjusted to meet specific product requirements, creating delicious Mochi with the perfect consistency and taste.

- Country

United States

United States Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in United States with advanced automated food production technology for making Dumplings, Egg Rolls, Empanadas, Spring Rolls, Burritos, Mochi, Quesadillas, and Spring Roll Wrappers. We also offer integrated solutions for popular foods such as Samosas, Momo, Pierogi, Tortillas, Shumai, Tapioca Pearls, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

People enjoy Mochi’s unique soft texture, and the variety of fillings available such as peanut, sesame, mango, sweet bean paste, matcha, vanilla, and other flavors. Mochi historically was a festive food item made for special occasions and ceremonies in certain Asian cultures; but recently Mochi has become a very popular and common dessert in Europe and the United States. Mochi is sold as a snack or dessert in many supermarkets and retail stores, and Mochi Ice Creams have recently become a Gen Z consumers’ favorite choice. Mochi Ice Creams are widely available in Walmart, Target, Kroger, and Asian markets such as 99 Ranch and H Mart in the United States. Vendors also came up with “Mochi kits” that include Glutinous rice flour, forming molds, dough cutters, and cooking instructions for consumers to make their own Mochi and Ice Cream Mochi at home. Additionally, Japanese Mochi craftsmen have also created artisanal Mochi (Wagashi 和菓子) that resemble flowers and art pieces. There are also variations such as grilled Dango, Strawberry Daifuku and Shiruko (a Japanese traditional dessert made with Mochi served in a hot Azuki bean soup). While Mochi continues to be one of the most popular traditional foods in Japan, its broad appeal has made it readily available in different styles and flavors all over the world.

- Handmade Recipe

-

Food Ingredient

Mochi Dough-Glutinous rice flour/Sugar/Coconut milk/Corn starch, Filling-Peanuts/Sugar/Peanut butter, Garnish-Shredded coconut

Prepare Mochi Dough

(1) Mix glutinous rice flour, coconut milk, and sugar together in a mixing bowl until it becomes a smooth paste without lumps (2) Pour the paste in a heated saucepan on medium heat, stir constantly for 6 to 8 minutes until it forms into a dough (3) Reduce the heat to low and continue to stir the dough until it becomes smooth and elastic, then take the pan off the heat to let the Mochi dough cool

Filling Making Steps

(1) Coarsely grind peanuts in a food processor (2) Mix the coarsely ground peanuts, sugar and peanut butter together

Mochi Assembly

(1) Sprinkle the work surface with corn starch, then divide the Mochi dough into equal pieces and roll them into balls (2) Flatten each Mochi balls with a rolling pin or by hand (3) Place a spoonful of peanut filling in the center of the flattened Mochi, then pinch the edges to create a beautifully filled Mochi (4) Coat the Mochi with shredded coconut on a plate and it is ready to be served

- Downloads

English

English