ANKO has Solved an Egyptian Company's problems with Sambousek Production

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products online, in supermarkets or deli. Selling products in multi sales channel had leaded to an increasing demand, so the company's owner, via a dealer, had been looking for a supplier who can offer an automated production solution. He was satisfies with ANKO's HLT-700XL model after conducting a test run at ANKO Taiwan headquarters. However, when the machine was commissioned in Egypt, dough was inelastic and couldn't be formed by the machine. The causes might be the characteristics of dough, the weather, or the effect of temperature and humidity. Fortunately, our engineer, who has many years' experience, immediately found the problem and adjusted the dough ingredients. Afterwards, the dough could be processed by the sambousek making machine normally.

Sambousek

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Dough is too inelastic to be formed with machine.

Dough was made with the same recipe and processed with the same machine model, but the results of the test runs conducted in Taiwan and Egypt were totally different. There are many causes, including flour brand, protein content, local weather, temperature, humidity, and even water quality. In order to solve the problem, our engineer changed……(Please contact us to get more information)

The contents of a type of food may be influenced by environmental variables. Two people make a dish with the same recipe. If they live in different countries, they might get the dish in different texture and taste. Flour is the most obvious example. ANKO has experience engineers and food researcher. Depending upon the character of local ingredients, we would systematically test and adjust recipes and machines until clients are satisfied with the texture and taste of final products, then provide the data and the way of adjustment for clients.

The chemical changes of food are so unpredictable. Only old hands are able to promptly give proper solutions to the unexpected problems.

Solution 2. How does ANKO's engineer do when clients want to alter their product size after delivery?

Our engineers are so qualified and experienced that they are capable of providing immediate custom processing services. Sometimes, after commissioning, clients would like to alter the look of their products for perfection. The machine doesn't need to be sent back to Taiwan. Our engineers are able to determine how to process the parts to satisfy clients' requirements. Then, the alteration can be done precisely by local factories or even by the engineers themselves.

After ANKO's adjustment, we helped the client make the perfect Sambousek. By simply changing the forming molds, HLT-700XL machine can also produce different ethnic foods.

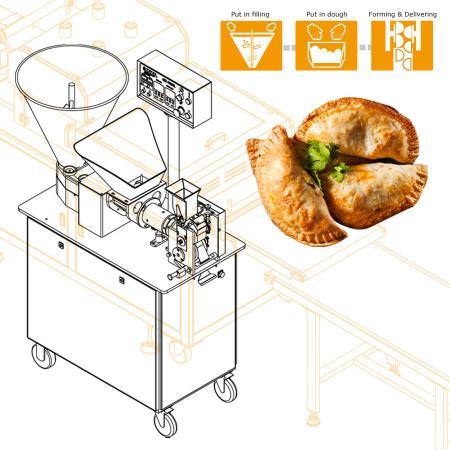

Food Equipment Introduction

- Put well-mixed stuffing in stuffing hopper.

- Put well-kneaded dough in dough hopper.

- Stuffing is extruded into a cylinder through stuffing pipe.

- Dough is extruded into a tube through dough pipe.

- While both cylindrical stuffing and dough tube are formed, stuffing is extruded into the dough tube.

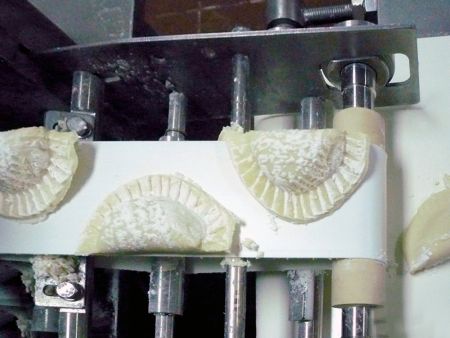

- With the forming mold, the stuffed dough tube is formed into the food shape as required.

- The final products are released from the mold by scraper.

- The final products are conveyed for the sequential baking process.

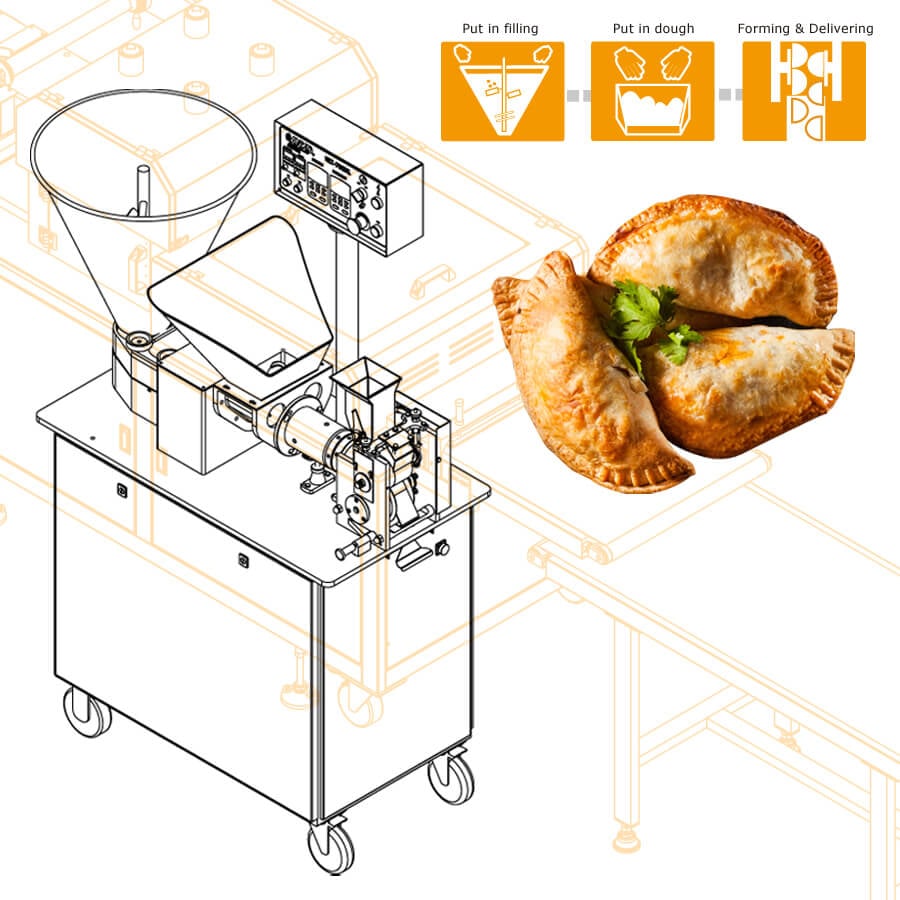

forming mold determines the look of a product.

forming mold in the HLT-700 series machines is responsible for the look of a product. It determines the product's size, shape, edge pattern, and edge thickness. In ANKO, over 30 kinds of forming molds are available. Clients could choose from these standard molds. We have half-circular or triangular mold for making samosa/sambousek, circular or square mold with wavy edges for making ravioli, etc. If clients would like to produce unique products, the forming mold can be customized. The sambousek in this case is made by a custom mold.

- Solution Proposal

ANKO Offers One-stop Production Solution for Sambousek

ANKO did

When building a Sambousek production line in a food manufacturing facility, people tend to put their focus on equipment procurement, but often neglected the importance of pre-planning with help from professional consultants, which may result in operational flow and related issues. ANKO provides you with Sambousek comprehensive production planning, professional consultancy, and guidance.

ANKO can help you more

A Sambousek One-stop Production Solution includes front-end and back-end equipment, such as vegetable cutter, meat grinder, dough mixer, forming/filling machine, packing machine and food X-ray inspection machine, etc. ANKO's professional consultant will plan the best solutions according to your specific requirement.

If you are interested in more inofrmation, please click Learn More or complete the form below.

- Machines

-

HLT-700XL

After putting the sambousek dough and stuffing into the hoppers, dough is extruded into a dough tube and filled with the mixture of cheese, spinach, and beef. Then, the filled dough tube is pressed into the sambouseks by a forming mold. The half-moon mold is widely used to make 13-gram to 100-gram products. The production capacity of HLT-700XL with the half-moon mold is between 2,000 and 10,000 pieces/hour. Moreover, it includes a built-in Internet of Things (IoT) system to provide real-time access to data monitoring to manage production better remotely. And having an inventory of spare parts and conducting regular inspections, companies can significantly reduce risks, reduce downtime, and enhance productivity.

- Country

Egypt

Egypt Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Egypt with advanced automated food production technology for making Kibbeh, Sambousek and Kofta. We also offer integrated solutions for popular foods such as Samosas, Falafels, Tortillas, Spring Rolls, Maamouls, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Sambousek is a common iftar dish during ramadan, which is similar to samosa; some consider them as the same food. Sambousek or samosa can be made into a triangle or half-moon shape with thick, fermented pastry or thin, unfermented (phyllo) pastry, stuffed with fried ground meat, onion, spices, etc. It is usually baked or deep-fried and served hot with salad, fattoush, or refreshing drinks such as watermelon pomegranate juice.

- Handmade Recipe

-

Food Ingredient

For wrapper-Flour/Salt/Butter/Oil/Water, For filling-Onion/Ground Beef/Pepper/Cinnamon/Salt

Making the Wrapper

(1) Add flour, salt, oil, butter in a large bowl and mix them evenly. (2) Add in water. (3) Mix all ingredients and knead the dough until smooth and elastic. (4) Cover with cling film and rest for an hour.

Making the Filling

(1) Chop onion and heat a pan. (2) Add oil and chopped onion in the pan. Stir-fry onion. (3) Add minced meat and stir-fry them until lightly browned. (4) Add pepper, cinnamon, and salt. Stir-fry seasonings and ingredients until combined.

How to make

(1) Dust the work surface. Then, roll out the dough into around 3 mm thick pastry. (2) Use a glass to cut out circles from the pastry. (3) Put a spoon of filling in the center of each circular pastry. (4) Fold them in half and seal the edges by pinching or pressing with a fork.

- Downloads

English

English