ANKO’s Automatic Pineapple Cake Production Line is set up for a New Product Launch for a Fijian Customer

It is a food and beverage company, producing frozen and fresh food, and owning over 30 casual dining restaurants. Most materials of the company's products are from its own farms. With the concept of providing organic food and additive-free products to consumers, the owner insists on growing plants with organic farming. The owner found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell them in his retail stores. However, he had no experience in making pineapple cakes. After having a discussion, we proposed a pineapple cake tailor-made total solution to him, including pineapple cake recipe, equipment, and training. Finally, he entrusted ANKO with the new product line.

Taiwanese Pineapple Cake

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Set up a production line to create a new product with what's in his farm.

The client likes to serve dishes and sell food products made with the plants grew in his farm. He usually creates a new product line based upon what he grows rather than what the market needs.

What he wanted to grow this time was organic pineapple, so he looked for pineapple-flavored or pineapple-filled products. Then, after trying Taiwanese pineapple cakes, he had decided to produce and sell pineapple cakes in his country. With the germinating idea, he met us at our booth in a trade show.

He had no automatic machine in his factory and without any experience to make pineapple cake before, so we developed a whole line, a recipe and, a training service for him. In addition, he told us what pineapple cake size he wanted, and then we customized pineapple cake molds for him. Now, his idea becomes pieces of golden pineapple cakes sold in his stores.

As long as an idea comes out of your mind, even though it's just you would like to make a fruit or vegetable you grow into some value-added products, we would turn the idea into a reality.

Solution 2. How to create a new product line from scratch?

What equipment does he need to make pineapple cakes?

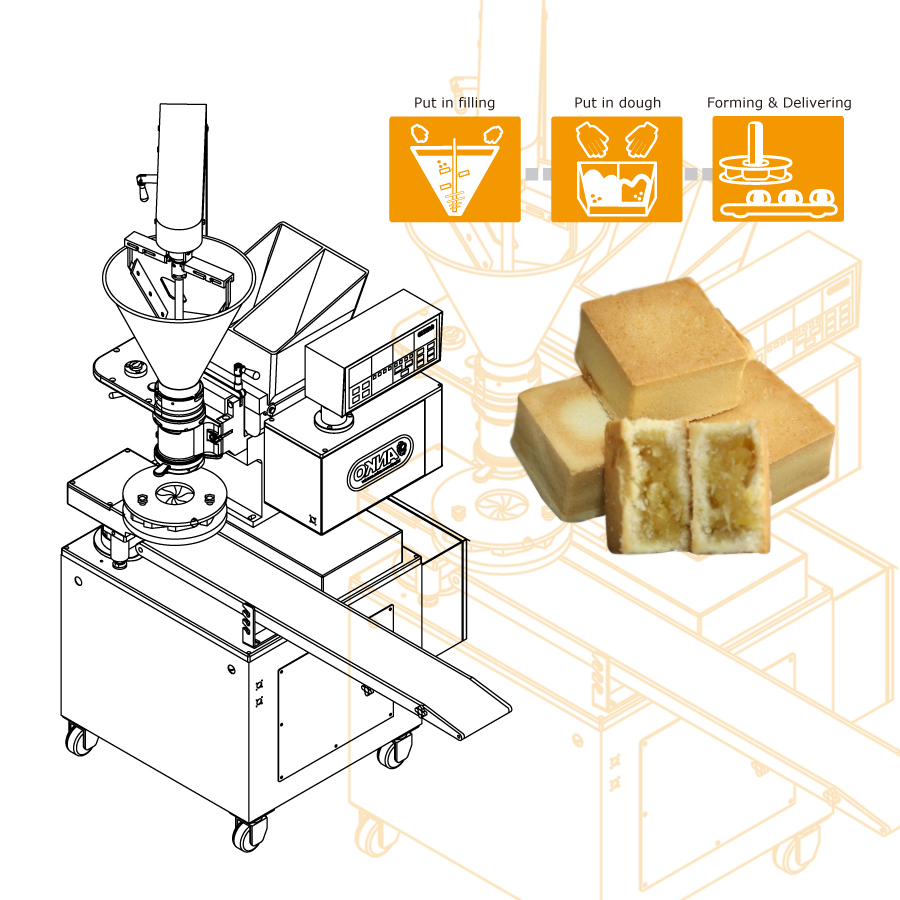

The whole line for making pineapple cake includes mixers, an SD-97W Automatic Encrusting and Forming Machine, a shaping machine, a tray loading and aligning machine, a pressing machine, and ovens.

ANKO mainly offers forming equipment but due to the fact that we have plenty of experience on recipe, production procedure, and machines, we are able to assist clients to set up the whole production line by cooperating with other suppliers.

In this case, the client chose the SD-97W model which has the productivity of 1,000 to 4,000 pieces per hour

How can he produce pineapple cakes without right recipe?

ANKO offers him a pineapple cake recipe with detailed instructions. The taste, texture, and other ingredients are able to be adjusted within a certain range. In this case, our engineer had adjusted the ratio of wrapper to filling as well as wrapper and filling hardness based upon the client's needs. In fact, a slight modification would affect the quantities of ingredients or machine settings. Therefore the more experienced an engineer is, the more flexible and customizable services a company could offer.

Providing the Best On-Site Operator Training

After the taste, texture, and appearance of the pineapple cake had met the client's requirement, we provided an on-site training, including not only machine operation, cleaning, and maintenance, but also daily parameter setting. Parameters for all machines need to adjust every day according to the filling and wrapper conditions which are affected by weather. The adjustment is very important before every use, so we don't just give the client a set of numbers but teach the operator how to examine filling and wrapper conditions and have a corresponding setting.

ANKO always test our machines before packing and shipping, to make sure they are in perfect working order

ANKO’s engineers help guide clients identify and differentiate between various ingredient consistencies, textures and characteristics

Solution 3. Make the dough ball fully fill in the baking mold

In order to make pineapple cakes with perfect appearance, there are two key factors:

1. The sizes of dough balls

2. The baking molds

in determining the machine performance and the look of final products. They need to be shaped into a cylindrical shape and we suggest when they are aligned the molds, the diameter of the dough cylinder should be one third higher than the depth of the mold, then the dough cylinder could fill in the corners of the mold perfectly.

Food Equipment Introduction

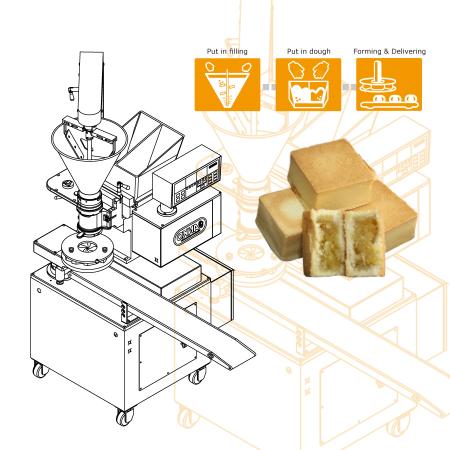

- Put the filling into the filling hopper.

- Put the dough into the dough hopper.

- The SD-97W extrudes the dough into a tube.

- The SD-97W extrudes the filling into the dough tube.

- The filled dough tube is divided by the shutter unit and formed into balls.

- The conveyor of the SD-97W delivers the balls to the shaping machine.

- The shaping machine rolls the balls into a cylindrical shape.

- The conveyor of the aligning machine places the cylinders into the molds.

- The pressing machine presses the dough cylinders into a square shape.

The ingenious design made the automatic pineapple cake production line turn into real.

Rolling, laying, and shaping - the processes before aligning stuffed cylinders in molds - are simple but important to improve the performance of production line. When the pineapple cakes are made by hand, we might not notice that we rub stuffed balls to fit them into molds. However, when switching to automatic production, R&D engineers need to consider all the details. The rolling, laying, and shaping processes are designed to make the stuffed cylinders smaller than the width of the molds and be horizontally located in the center of the molds so that the stuffed cylinders can be placed in position and pressed evenly.

Good baking molds are the key to make pineapple cakes with a perfect look.

Traditionally, mold and baking pan are made together, but now the mold are separated from baking pan and made into individual molds. What are the advantages of the modular molds? First of all, clients can customize one or several sets of molds depending on the size of their baking pans or products. Second, in order to perfectly brown every surface of a pineapple cake, there are spaces between the molds in same distance. Last but not least, the small, individual molds are easier to clean than a large mold pan.

- Solution Proposal

Unlock business opportunities with ANKO's tailor-made total production solution for Pineapple Cake

ANKO did

Our Pineapple Cake Production Line, incorporating the SD-97W Automatic Encrusting and Forming Machine, shaping machine, aligning conveyor, tray loader, and pressing machine, revolutionizes the complex manual processing of pineapple cakes into an efficient automatic production line, slashing labor costs and saving valuable time.

ANKO can help you more

For enhanced automation, ANKO offers expert planning for front-end and back-end equipment, including dough mixers, packaging solutions, and food X-ray inspection machines, to support not only Pineapple Cakes but also other bakery products. Our team of professional consultants will evaluate your current situation and craft a customized production plan based on your requirements.

Explore the endless possibilities with ANKO and turn your Pineapple Cake vision into reality today! Click Learn More or complete the form below to discover how we can elevate your business to new heights.

- Machines

-

SD-97W

SD-97W is a multi-purpose automatic encrusting and forming machine that is especially designed to make stuffed products. It is capable of connecting with other devices and machines to automate the sequential processes such as shaping, stamping, rounding, etc. To make pineapple cakes with the SD-97W, the weight and the ratio of wrapper to filling can be standardized.

Being a pioneer in the automated food machine industry, ANKO launched the Internet of Things (IoT) System, using AI to integrate our automatic food production lines. The SD-97W includes the IoT system that intelligently integrates food production lines. Through mobile devices, production status can be monitored remotely, and the IoT also produces machine maintenance schedule reminders, significantly reducing the risk of downtime while providing our clients with more time to focus on food production.

- Video

How does the pineapple cake production line work?The pineapple cake production line involves forming, shaping, placing, and pressing. The SD-97W Automatic Encrusting and Forming Machine is able to form pineapple filling balls in uniform size and weight. Then, through the shaping processes, the stuffed balls can be placed correctly in the center of molds. Lastly, the pressing machine presses the molds in batches.

- Country

Fiji

Fiji Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Fiji with advanced automated food production technology for making Dumplings and Pineapple Cakes. We also offer integrated solutions for popular foods such as Samosas, Rotis, Naans, Chapatis, Parathas, Cassava Balls and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Pineapple cake is a traditional Taiwanese pastry. In 1970s, pineapple was the second-largest agricultural product in Taiwan. People used abundant pineapple to make canned pineapple, jam, preserve, and Chinese pastry. At first, pastry chefs added pineapple stuffing into Chinese bride cake. The pastry was made with lard, wrapped around a mixture of pineapple and winter melon jam which was used to reduce sour taste of pineapple.

Now, the pineapple cake is made into a cube and completely stuffed with pineapple jam. It becomes one of the most popular Taiwanese souvenirs because the aroma and taste are loved by tourists.- Handmade Recipe

-

Food Ingredient

For wrapper-Butter/Icing Sugar/Egg/Cheese Powder/Milk Powder/Cake Flour/All Purpose Flour, For filling-Pineapple/White Sugar/Malt Sugar/Butter/Sweet rice flour

Making the Wrapper

(1) Soften butter and add icing sugar, then mix them until all combined. (2) Add cheese powder and whole milk powder in the same bowl and mix them until combined. (3) Beat eggs and add 1/3 beaten eggs at a time in the bowl and mix until combined. (4) Sift 1/2 cake flour and 1/2 all purpose flour at a time in the bowl and knead until combined. (5) Divide the dough into equal portions.

Making the Filling

(1) Remove skin from the pineapple and dice the fruit, then place diced pineapple with its juice into a pot. (2) Add sugar to the pot and bring the mixture to a boil, then add malt sugar and turn on the heat to a low to simmer. (3) When the pineapple compote reduces to a thick consistency, add butter and sweet rice flour in small batches and mix well. (4) Let the compote cool and then divide the pineapple filling into small portions.

How to make

(1) Press dough balls into a flat round shape. (2) Put a portion of filling on the center of a dough wrapper. (3) Seal the dough wrapper. (4) Put the pineapple ball into a mold and press it to fill the mold. (5) Bake the pineapple cakes for 10-12 minutes. (6) Take out from the oven and flip the pineapple cakes over. (7) Bake them for another 10 minutes.

- Downloads

English

English