Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

ANKO's food machines are suitable for different scales of central kitchens or cloud kitchens to assist your restaurant chains, delivery-only restaurant, or catering service on mass-producing consistent quality food, minimizing costs, and saving time.

With the growth of demand, ANKO's value is to help clients increase efficiency and seize food business opportunity through our food production solutions.

You can find more successful cases that have helpful food solution information you need below or send an inquiry to us now!

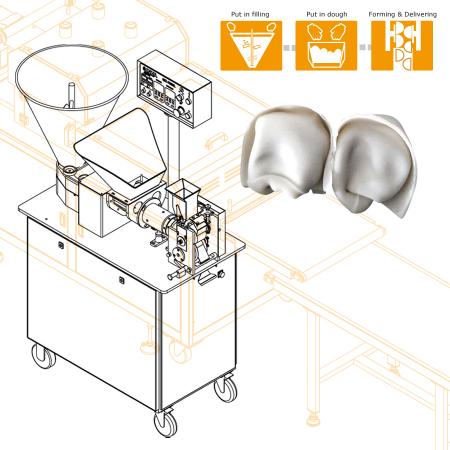

20 years ago, a Chinese restaurant opened, serving Shanghai style dim sum which then became popular with the local people. However, the issues of labor shortage, limited capacity, and workload drove the owner to make a change. During his visit to ANKO, he had good experience with ANKO's machine trial service. During the visit, both of us could have a better understanding of each other. Based upon his ideas, concerns, and needs, we customized two forming molds to help him mass-produce shanghai wontons that were complicated to fold by hand. With ANKO's HLT-700XL, now the owner doesn't bother to recruit and train cooks and can increase capacity to meet demands.

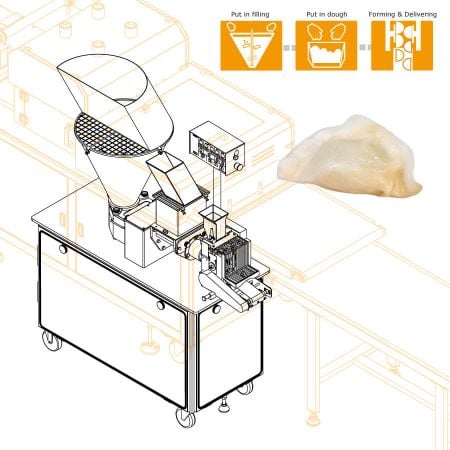

Customers want to increase production capacity by moving from manual to automatic production. However, sometimes machine-made dumplings cannot meet their required shape. Either customers have to give up having handmade pleats and delicate patterns or they stay in manual production. Dumpling machine has been ANKO's bestseller. We have received many inquiries about dumpling shapes. "Do you have other more natural patterns?", "Do you have pinching patterns?", "Do you have other pinching patterns?", "Why is the machine-made dumplings not mouth-watering?" and so on. To response these demands, we started a series of development processes.

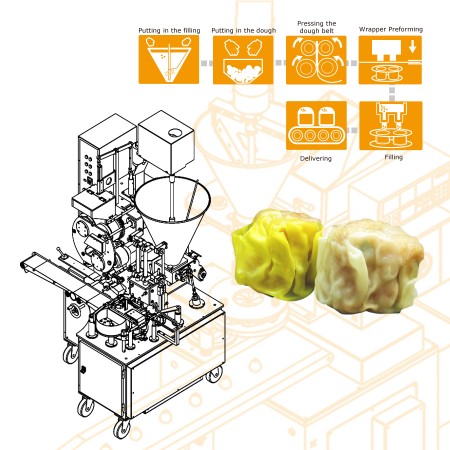

To boost production capacity, the client transitioned from manual to automatic manufacturing and contacted ANKO for a production solution. Initially, we recommended a Double-line Automatic Siomay Machine. Within two years, their number of restaurants had tripled. They then approached ANKO again to purchase another Siomay Machine to meet the demand from all their restaurants.

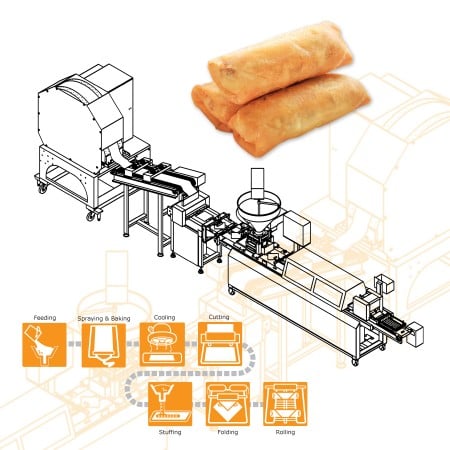

The client runs restaurants, Indian food retail stores, and food factories at the largest Indian community in Birmingham, UK. Their major consumers are the Indians in the UK. Years ago, the client bought a food machine from ANKO. Without a machine trial before purchase, its user-friendly design, intuitive operation, and stable production and ANKO's services gave him a great impression. Therefore, he placed another order for spring roll production line this time because he thinks ANKO is reliable. (The SR-24 is no longer available. The new model is SR-27 machine.)