Kompia Production Line Designed to Solve Problem That Demand Exceeds Supply

The owner's kompia is so delicious that people are willing to travel a long way to his store in a rural area. However, 1,000-1,200 kompias made by five people a day were not able to meet the demand. That made people feel disappointed and sometimes brought customers into conflict. The client contacted ANKO's Malaysian distributor for SD-97SS, but after a machine trial, ANKO's engineer thought that the HLT-700XL and EA-100KA was more suitable for kompia dough that was firmer for making crispy kompia, while the SD-97SS is suitable for soft fermented dough for creating fluffy texture. Therefore, our engineer immediately decided to use HLT-700XL and EA-100KA to make some samples. With the samples and ANKO's soft power of food and ingredients, the client had complete confidence in us and placed an order.

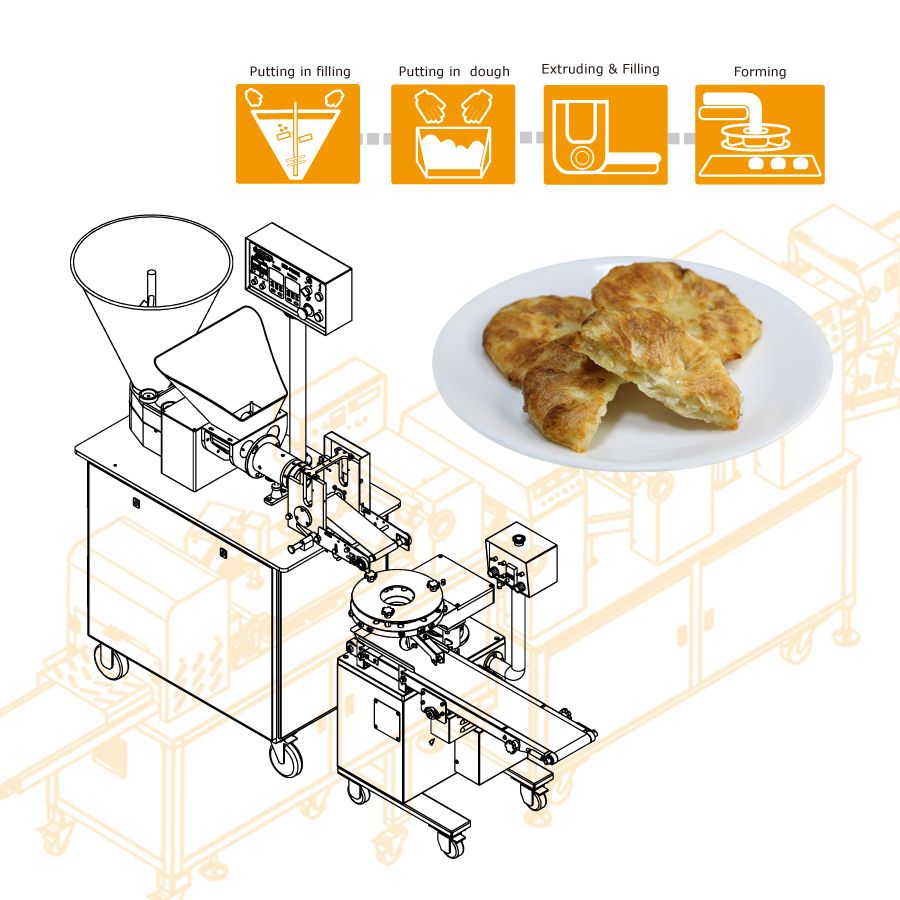

Kompia (Kompyang)

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Maintain handmade texture by using wrapper thickness adjustment mechanism.

Kompia is cooked in a preheated Chinese oven. While the wrapper is being cooked on a high heat, the heat enters into kompia through very thin wrappers to heat the lard and sauté the onions until their aroma comes out.

At first the wrapper of the machine-made kompia was too thick, which would block heat from entering inside. To solve the problem, poking more holes on the machine-made kompia might work, but our engineer considered that poking more holes by hand would increase working hours and three holes were the feature of his kompia. Therefore, our engineer would prefer to do more research on his recipe and our machine, rather than change these features that had made the food delicious.

Our engineer, based on his experience, kept trying and communicating with the client. After testing three times, the machine-made kompia was finally as thin as the handmade one.

How thin is the wrapper of the machine-made kompia? It is around 2 millimeters after forming by machine and then rolled into a 1-millimeter thin wrapper that is as same as that of soup dumpling.

Solution 2. Quantify the owner's recipe and establish an SOP to stabilize characteristics of dough.

The client had years of experience in making kompia. He kneaded dough by hand, measured flour and water based on his judgement, and added fermented dough to new dough. However, they were variables when switching to automatic production. We assisted the client with the standardization of a recipe and production process to maintain quality consistency and save time testing dough before every production.

Moreover, the texture of the dough, which added handmade fermented dough, was slightly different after being extruded by machine in this case. Compared to the handmade kompia, the machine-made kompia was smoother.

According to our engineer's experience, the texture could be adjusted ...→To get more information? Please Click Contact Us Below

Solution 3. After switching from manual to automatic production, what things might need to be rearranged in production?

More ovens needed to deal with the increase of production capacity

It was expected that after stable production the existing production capacity would increase significantly. By then, the original three Chinese ovens would not be able to bake in time. Therefore, we recommended that the client should start planning to buy more ovens.

Chop red onions smaller to make the production run smoothly

When the machine divided and formed kompia balls, sometimes the large red onion dices were in the middle and made the balls unable to be sealed completely. We advised the client to chop red onions smaller so that the machine can operate stably. On the other hand, having a vegetable cutting machine was also recommended to not only control the size of red onion dices, but also maintain quality consistency.

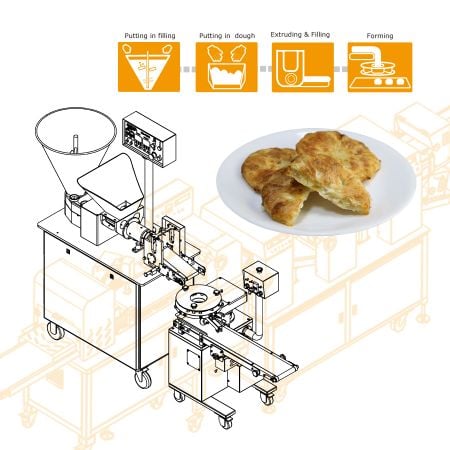

Food Equipment Introduction

- Extruding dough and shaping it into a hollow tube.

- Extruding filling into the dough tube.

- Conveying.

- Dividing the cylinder of filled dough into semi-final kompia balls.

HLT-700XL allows users to adjust wrapper thickness easily.

HLT-700XL features quick and easy adjustment of dough thickness, even the owner's son, an adolescent, can quickly learn how to adjust. By simply turning a special mechanism to widen or narrow the distance between filling and dough devices, the machine can extrude dough tubes in different thickness. the wider the distance is, the thicker the dough tube is.

Moreover, users can adjust the dough thickness anytime. For example, before the client quantified his recipe, we turned the mechanism to adjust the kompia wrapper thickness every production according to characteristics of each dough.

- Solution Proposal

ANKO Kompia Machine produces delicious flavors with its distinctive product characteristics

ANKO did

With over 48 years of experience, our professional team excels in creating the best food products using our equipment. By transitioning to automation, clients can effortlessly produce Kompia at a rate exceeding 2,000 pieces per hour, addressing both insufficient supply issues and the global labor shortage.

ANKO can help you more

For clients with significant demand for Kompia, ANKO can establish a fully Automatic Kompia Production Line. The process begins with a dough mixer to blend the flour and other ingredients thoroughly. Subsequently, the HLT-700XL and EA-100KA machines divide the dough into small portions. Additionally, we can design a dough resting conveyor with a sesame sprinkling device to minimize manual work. Finally, clients can opt for additional equipment such as baking or packaging machines to save time and effort. Please click Learn More to initiate your One-stop Kompia Production.

- Machines

-

HLT-700XL+EA-100KA

The HLT-700XL Multipurpose Filling and Forming Machine helps the clients to mass-produce kompia, and with the adjustment device of dough thickness, the kompia wrapper can be made extremely thin. Moreover, the amount and extruding speed of dough and filling are able to be adjusted easily on the control panel. The EA-100KA Forming Machine helps divide the cylinder of filled dough into semi-final kompia balls. With automatic production, all kompia will be in the same weight and with same amount of dough and filling. Also, the EA-100KA seals the opening well while dividing to prevent the kompia bursting, which can reduce defective products and food waste.

- Video

How do the HLT-700XL and EA-100KA produce kompia? After putting dough and filling in the hoppers, the machine can automatically extrude a dough tube and fill stuffing into the dough tube, then the filling dough is conveyed to the EA-100KA that will divide the cylinder of filling dough into kompia balls.

- Country

Malaysia

Malaysia Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Malaysia with advanced automated food production technology for making Siew Mai (Shumai) and Kompia. We also offer integrated solutions for popular foods such as Curry Puffs, Dumplings, Bagels, Spring Rolls, Wonton, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Kompia is served as snack and has variants. Generally, there are stuffed kompia and non-stuffed kompia. The non-stuffed kompia is more like bagel and the stuffed kompia is similar to savory stuffed bread consisting of minced meat and/or vegetable filling and thin crispy skin.

The client's kompia is the stuffed kompia. It is simply stuffed with lard and onions and formed into a ball like baozi, then rolled out. Finally, the round kompias are slapped onto the inner surface of Chinese ovens and baked until they are brown.- Handmade Recipe

-

Food Ingredient

For wrapper-Flour/Water/Fermented Dough/Salt/Alkaline/Baking Soda Water, For filling-Lard/Red Onion/Salt/Flour

Making the Wrapper

(1) Mix flour, salt, water, and fermented dough together. (2) Add some alkaline or baking soda water as required.

Making the Filling

(1) Chop red onion. (2) Mix chopped red onions, lard, and flour together. (3) Season the mixture with salt.

How to make

(1) Divide dough into small dough balls. (2) Roll a dough ball into a round wrapper. (3) Scoop filling in the center of the wrapper. (4) Seal the wrapper. (5) Roll out the stuffed ball until the wrapper is very thin that you can see the filling through. (6) Poke three small holes on the top of the kompia.

- Downloads

English

English