ANKO’s Spring Roll Production Line provides Solutions for a Jordanian Client’s Vegetable Spring Roll Manufacturing Issues

The client's products are Halal food, including spring roll with vegetable stuffing, chicken and onion stuffing, cheese stuffing as well as beef stuffing, permissible for Muslims. At the end of Ramadan, fasting was not required. It was the time for people to go shopping and buy food; as a result, the client received a large number of spring roll (cigar roll) orders. He uses three semi-automatic spring roll production machines, which need employees to wrap rolls by hand. Anko machines are satisfying for him. For the reason, the client considered to order a new spring roll machine with special folding and rolling device, in order to reduce labor costs, increase capacity, and control the quality of standardization. (The SR-24 is no longer available. The new model is SR-27 machine.)

Spring roll

ANKO Team Research Problem Solving or Solution Delivery

The shredded vegetable was too long and had too much juice that caused the problems of unstable feeding and unsmooth producing process.

The vegetable stuffing had enough oil as lubricant; it was supposed to be extruded smoothly. The problem is that the shredded vegetable was too long to be fed in position. In addition, The vegetable stuffing had too much juice, which leaked on feeding system base.

The solution could be -

(1). Cut vegetables shorter than ...(Please contact us to get more information)

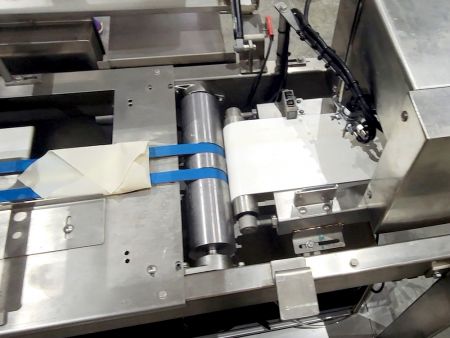

Vegetable Spring Roll Filling Extruding Process – After ANKO’s suggested adjustments, the vegetable filling is placed on the wrapper properly and then one corner of the wrapper is folded to cover the filling. The entire process is s consistent and efficient.

Food Equipment Introduction

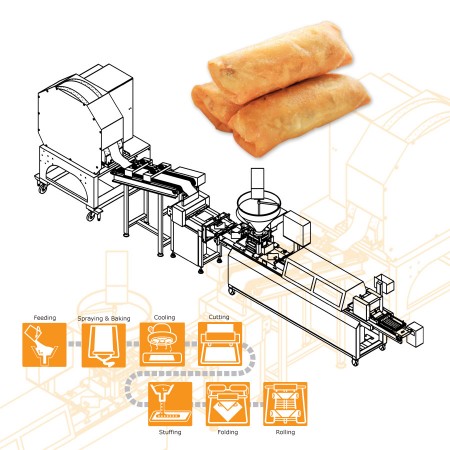

- Pour cooked stuffing into hopper.

- Pour mixed batter into batter tank.

- Set the temperature.

- Bake wrapper belt.

- Cool wrapper belt under fans.

- Cut wrapper belt into 200mm*200mm squares.

- Turn cut wrapper in position, ready to be fed with stuffing.

- Feed stuffing: locate stuffing on a set place.

- Fold wrapper: fold the first corner to the center to cover the stuffing, and then seal the stuffing by left and right side flappers.

- Roll up: roll up toward the last corner under rolling net, at the same time, seal the end.

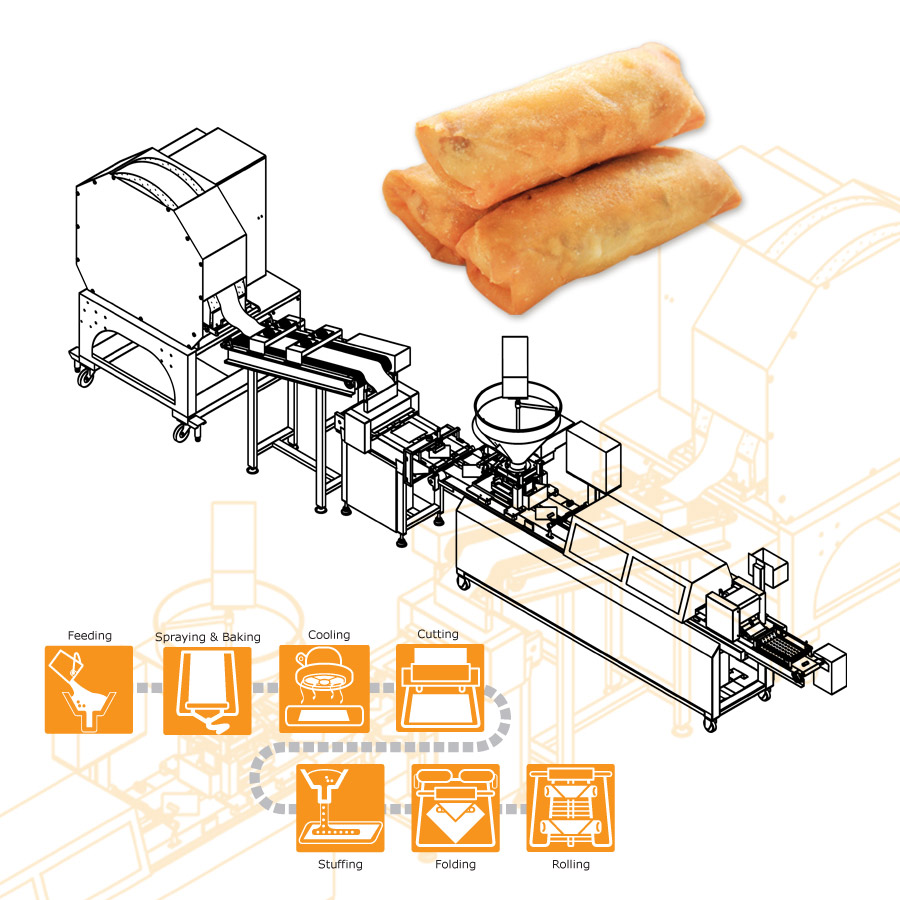

Fundamental of Design

- Our team found that, as spring roll wrappers pile up, the spring roll wrappers commonly stick together. Therefore, we designed a cooling system, which not only solves the problem, but also connects the wrapper producing process and wrapping process in a sequential producing line.

- The humanlike folding device and sensor imitate hand gestures and eyes. The sensor is capable of detecting the positions of wrapper and stuffing, making stuffing be wrapped up properly. Also, the last rolling device and stainless net form spring rolls like handmade.

- Solution Proposal

Optimize Your Production with ANKO's Premium Spring Roll Production Line

ANKO did

ANKO's Spring Roll Machine can process a wide range of fillings, such as vegetables, meat, cheese, mix of vegetables and meats, etc. With the upgraded filling system and our professional food expert, we can turn your desired fillings into real production.

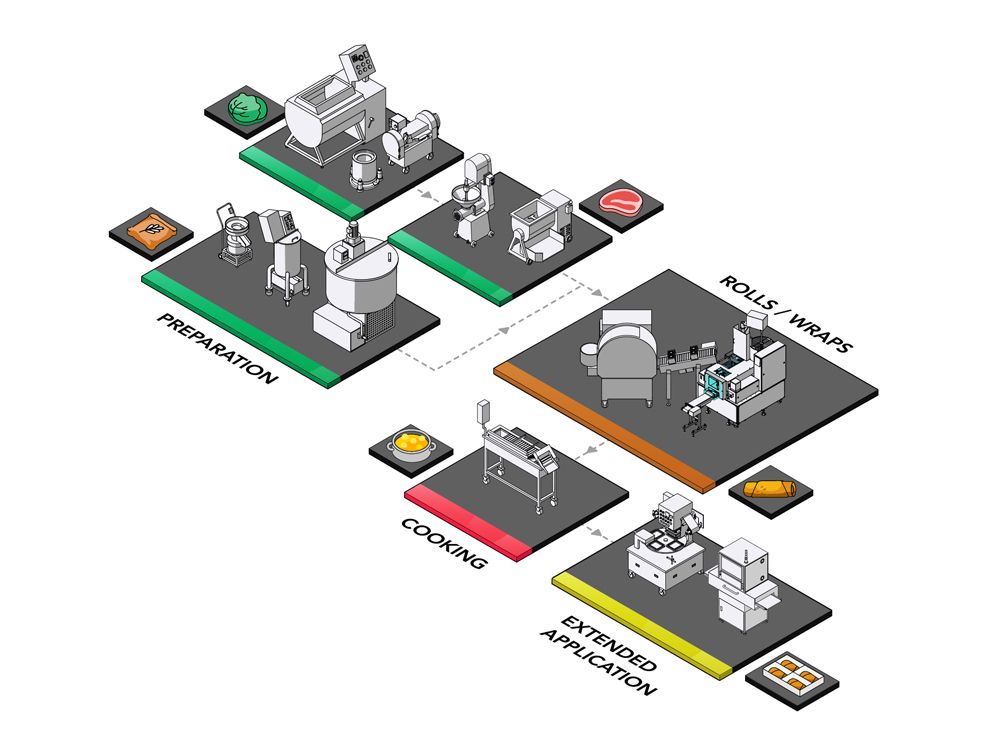

ANKO can help you more

Besides the Spring Roll Machine, we can also offer the machines for preparation, rolling and wrapping, cooking, packaging and food inspection to set up a highly efficient production line with a minimum number of workers. It can save labor costs and increase production capacity. Food Companies can benefit from ANKO's Spring Roll Production Solutions.

If you are interested in getting more information, please click Learn More or complete the form below and we will get back to you as soon as possible.

- Machines

-

SRPF-45

SRPF-45 Semi-automatic spring roll and samosa production line is equipped with a large round baking drum with functions of adjustable wrapper width, thickness and temperature control. The capacity is up to 5400 pieces per hour. With cooling and cutting processes, spring roll wrappers are ready for filling by stuffing depositor. The stuffing depositor is also designed to meet individual requirements of stuffing size and weight as long as a machine part or data is changed or reset. Furthermore, there is a sensor to assure the customized stuffing locates on exact place.

SR-24

SR-24 spring roll production line not only has the same advantages as SRPF-45, but also equips special folding and rolling systems, which imitate hand gestures to fold and roll up every spring roll. The maximum capacity reaches 2400 pieces per hour. (The SR-24 is no longer available. The new model is SR-27 machine.)

- Video

The Process of SR-24 Spring Roll Production – SR-24 Automatic Spring Roll Production Line can produce rolls that are 10cm in length, and 2.5-3cm in diameter. The entire production line is designed with high safety protection standards, and the baking drum has a special heat insulation to prevent accidental burns during operation. The microcomputer thermostat controls the Spring Roll wrapper cooking time and temperature to ensure the quality of all products. This automated machine is highly recommended for food factories, central kitchens, chain restaurants and other food establishments.

- Country

Jordan

Jordan Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Jordan with advanced automated food production technology for making Spring Rolls, Kubba Mosul Pastries and Kibbehs. We also offer integrated solutions for popular foods such as Maamouls, Arabic Breads, Samosas, Sambouseks, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Spring roll originated in China, even its name was translated literally from Chinese. "Roll" implies its shape; "spring" symbolizes the season of renewal. In Chinese culture, eating spring roll represents a new year coming and a fresh beginning. Everyone wishes all the best in the year. From place to place, spring roll has several names such as Lumpia in Southeast Asia, cigar roll in Middle East, egg roll in America. However, the recipe has minor differences. People wrap up sweet or savory stuffing with a thin wrapper, which is mainly made from flour and then deep fry it.

- Handmade Recipe

-

Food Ingredient

Spring Roll Wrapper-Flour/Salt/Water, Filling-Ground Chicken/Cabbage/Garlic/Scallions/Carrot/Soy Sauce/Black Pepper/Oil/Corn Starch/Water

Spring Roll Wrappers

(1) Pour flour, water, and salt in a bowl and well stir them. (2) Add a little bit oil on a fry pan and use kitchen towel to wipe the oil thinly and evenly. (3) Pour a ladle of mixture and roundly tilt the fry pan to spread the mixture evenly. (4) Until the wrapper side peels off, cook the other side for a few seconds.

Making Spring Roll Filling

(1) Shred cabbage, scallion, and carrot, and set aside. (2) Heat cooking oil in a wok and fry ground chicken till it has been slightly browned, and set aside. (3) Add cooking oil again to sauté garlic cloves, scallion, and shredded carrot until aromatic, then fry cabbage and ground chicken together, season with soy sauce and black pepper. (4) Cool the filling on a tray and tilt the tray to collect and discard unneeded liquid.

Wrapping

(1) Mix corn flour and water as wrapper glue. (2) Put chicken and vegetable filling at a corner of wrapper and roll the wrapper half-way from the corner. (3). Then smear glue on left and right corner and fold up, smear glue on the last corner and roll up tightly.

Cooking

(1) Pour the oil in a wok or fry pan until it's enough to completely cover the spring rolls. (2) Preheat the oil to about 160°C. (3) Carefully place the spring rolls into the oil and deep fry them. (4) Ready to enjoy!

- Downloads

English

English