Creating Non-Sticking Glutinous Rice Ball Production Equipment for ANKO's Client in Hong Kong

The client sells a great variety of foods. Although glutinous rice ball was not one of the main products, he needed a solution to produce glutinous rice balls effectively. Therefore, he visited ANKO's booth at a Hong Kong exhibition. Compared to other glutinous rice balls, the client's filling recipe contains more ingredients, including peanut powder, coconut powder, and sugar powder, which makes workers hard to fill the same ingredient quantities into each glutinous rice ball. Nevertheless, it is also difficult for machine to extrude powder filling because it easily tends to clump up and clog the filling system. Therefore, for making stuffed food with powder filling, ANKO's Automatic Encrusting and Forming Machine with a special designed powder filling system is highly recommended.

Glutinous Rice Ball (Mochi)

ANKO Team Research Problem Solving or Solution Delivery

Preventing Glutinous Rice Balls from Sticking and Deforming upon removal from the Conveyor Belt

Glutinous Rice Balls have a unique sticky texture, which requires the use of a significant amount of rice flour to prevent them from sticking during the time-consuming manual production process. The ANKO SD-97W Automatic Encrusting and Forming machine makes Glutinous Rice Balls substantially more efficient. Issues with the product sticking and deforming were resolved by replacing the conveyor belt with a circular tray sprinkled with rice flour.

Handmade Glutinous Rice Balls require large amounts of starch powder to prevent the products from sticking

Food Equipment Introduction

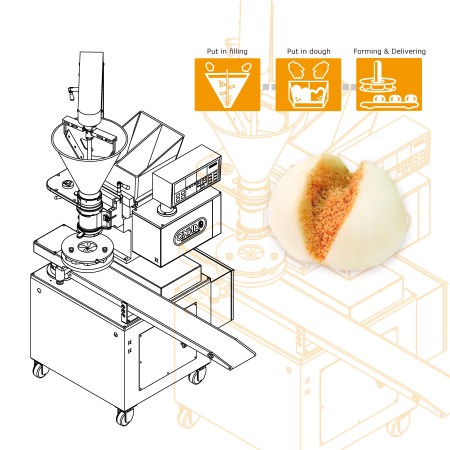

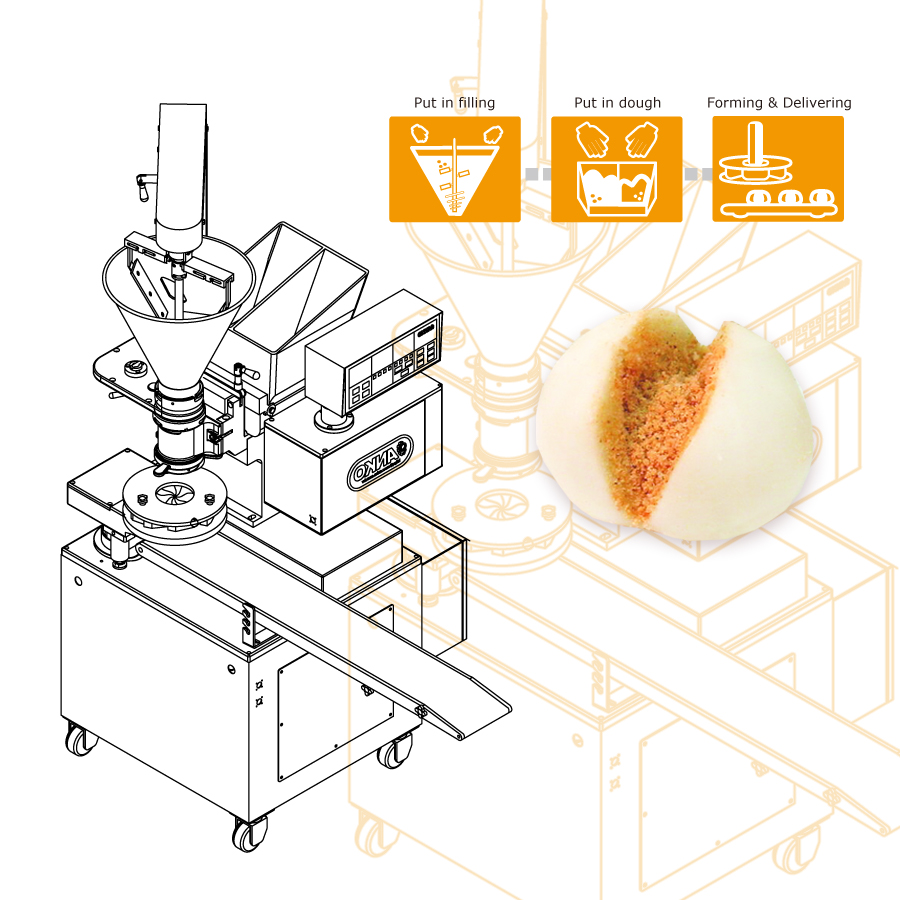

- Put mixed powder filling into the filling hopper

- Put prepared glutinous rice dough into the dough hopper

- Extrude filling and glutinous dough into a cylinder

- Divide it into equal balls by the shutter unit

Crafting a Filling System Suitable for Wet and Dry Fillings

Most automatic filling and forming machines employ a filling extrusion mechanism. For pliable fillings like chocolate, red bean paste, or meat and vegetable fillings, extrusion works smoothly. However, powdered fillings can clump due to excessive stirring, leading to unwanted high temperatures and pressure. Additionally, exposure to air can cause moisture absorption, negatively affecting the filling process. ANKO developed a unique design mechanism specifically for drier fillings to address this. It mimics a hand-turning motion, allowing powders and dry fillings to flow smoothly. When used with our corresponding filling nozzles, this system prevents clumping and blockages during the filling process.

- Solution Proposal

ANKO's Glutinous Rice Ball Production Solution Streamlines Your Transition from Manual to Automated Production

ANKO did

In this case, the client used powder filling for making Glutinous Rice Ball (aka Mochi) and requested a machine with medium-large production capacity. ANKO's SD-97W Automatic Encrusting and Forming Machine can meet client's needs. Besides, the famous Mochi Ice Cream, one of the hottest foods to hit the market in recent years, is also capable of producing via SD-97W machine.

ANKO can help you more

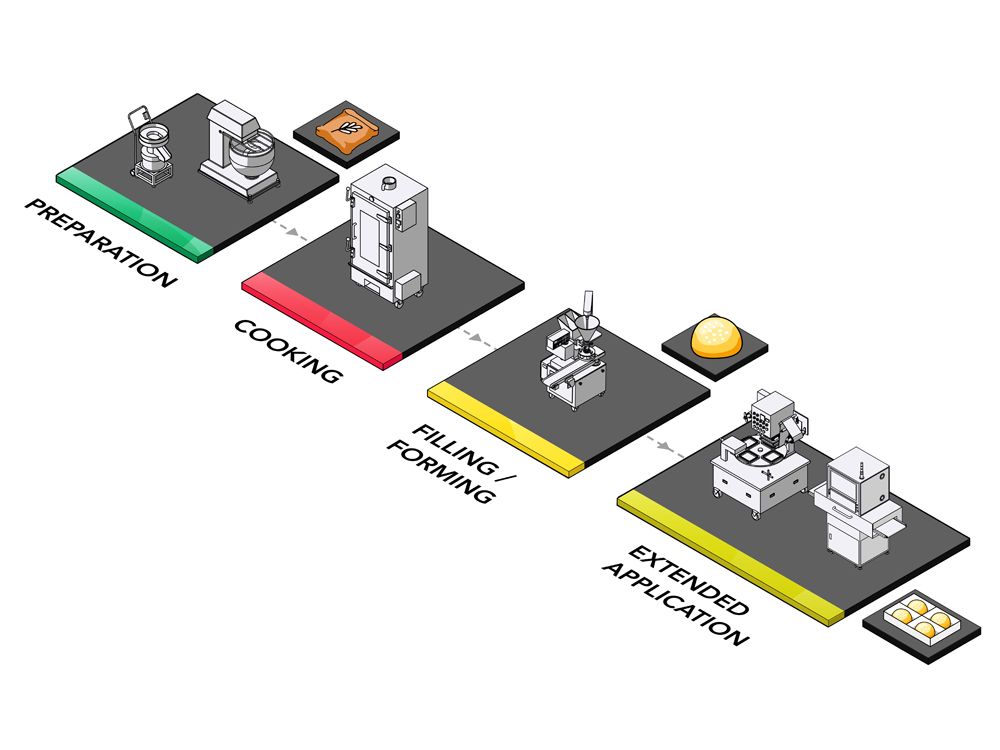

Not only the forming machine, ANKO can also offer ingredient processing machines, steamer, packaging and even X-ray inspection machines to integrate an automated Glutinous Rice Ball Production Line, which is suitable for food factories, central kitchens, sweet/snack shops, etc. According to your request, ANKO can customize the specific solution for you.

If you are interested in more information about ANKO machines, please click Learn More or fill out the inquiry form below.

- Machines

-

SD-97W

By changing different filling, dough, and forming mold sets, the SD-97W machine can make a wide variety of food, such as bao, tang yuan, kibbeh, coxinha, cookie, mochi, and other stuffed food products from 10g to a maximum of 70g per piece. It can also produce products with deep pleats, light pleats, and non-pleats, or in different shapes with different shutter units. In this case, the SD-97W is equipped with a powder filling system, a non-patterned shutter unit and a turning round tray to collect sticky glutinous rice balls.

Moreover, SD-97W is includes a built-in IoT system, using AI to integrate automatic food production lines. Managers can monitor all the manufacturing data, such as production yield rate, material waste, production issue reports, etc to improve manufacturing downtime and operation. IoT Big Data can be utilized with extended applications to manage production balances, logistics, warehousing, inventory, and scheduling in the future.

- Video

ANKO's SD-97 series Automatic Encrusting and Forming Machine extrudes dough tube and filling inside at the same time. Then, the stuffed dough tube is divided into small balls and collected by the turning round tray, which is covered with a layer of rice flour in order to prevent sticking as well as save labor and time. The production capacity of the SD-97SS shown in this video is around 1500-3600 pcs/hr. And the SD-97W can make about 2500-4200 pieces per hour.

- Country

Hong Kong

Hong Kong Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Hong Kong with advanced automated food production technology for making Har Gow, Tang Yuan, and Glutinous Rice Ball (Mochi). We also offer integrated solutions for popular foods such as Dumplings, Shumai, Wonton, Dim Sum, Meatballs, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Glutinous Rice Balls are traditional Chinese snacks popular in the southern regions of China, Hong Kong, and Macau. They are made with steamed glutinous (sweet) rice and pounded into a thick and sticky texture, commonly served coated with a thin layer of soy flour or black sesame seeds. The recipe for making this sticky rice treat has evolved as it becomes more popular worldwide. These treats are also known by names such as Sticky Rice Balls, Mochi, and Daifuku. Nowadays, most people mix glutinous rice flour with other starches, then heat the mixture in a steamer (or microwave) until it is cooked. The now-formed Glutinous Rice Balls are filled with various ingredients. Traditional filling ingredients include sweet ground peanuts, sesame powder, and red bean paste. In recent years, exotic mango filling has become a popular new flavor, while durian, custard, purple sweet potato, and matcha flavors were also created. In the United States, a Japanese American created "Mochi Ice Cream," wrapping Glutinous Rice wrapper around ice cream. This became very popular, and the trend spread back to Asia. Mochi Ice Cream has become a typical dessert served after meals and a popular choice for festive occasions and gifts among friends and family. With the increase in health consciousness, a trend towards low-sugar and low-fat Glutinous Rice Balls and sugar-free or keto-friendly recipes emerged online, providing consumers with guilt-free alternatives.

- Handmade Recipe

-

Food Ingredient

For wrapper-Whole Milk/Condensed Coconut Milk/Glutinous Rice Flour/Icing Sugar/Corn Starch/Butter, For filling-Icing Sugar/Peanut Powder/Coconut Powder

Making the wrapper

(1) Melt butter in a double boiler. (2) Put glutinous rice flour, cornstarch, icing sugar, milk, condensed coconut milk in a large bowl. (3) Stir and mix them together until no lump remains. (4) Add melted butter into the large bowl and mix them well. (5) Steam the batter in a steamer for around ten minutes. The batter will turn into springy dough. (6) Put the dough into another bowl and cover with a cling wrap. Set aside to cool it.

Making the filling

Mix icing sugar, peanut powder, and coconut powder in a bowl.

How to make

(1) Divide the glutinous rice dough into equal portions. (2) Cover a small dough ball with a cling wrap. (3) Use a rolling pin to roll the dough ball into a circular wrapper. (4) Put a spoon of powder mixture in the middle of the wrapper. (5) Pinch the edge and shape the glutinous rice ball into a round shape.

- Downloads

English

English