ANKO configures an exclusive Tang Yuan production line to create market opportunities for a client in Hong Kong

The client runs meat processing business which has long history and gains high market share. Now it is the turn that the second generation entrepreneur takes over the company. With current frozen equipment and packaging machinery, they would like to increase efficiency and develop other snacks with product line expansion. ANKO's machinery features multifunction. Take the Automatic Encrusting and Forming Machine as an example, various kinds of dough and filling are suitable for the machine; through parameter adjustment, a wide range of products can be made with one machine. For manufacturers, it definitely a worthy investment to receive a high price/performance ratio.

Tang Yuan

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. How to prevent glutinous rice dough from drying and cracking as dividing?

SD-97W is designed to stuff diversity fillings such as bean paste, meat paste, sesame paste, and peanut powder. As for dough, not only dough with different levels of gluten but also gluten-free dough is suitable for this machine type. Tang yuan dough is made with a precise ratio of glutinous rice flour to water. Dough with too much water cannot be form, whereas dough with too less water may crack. Moreover, time is one of factors. As dough is exposed to air too long, the outside of dough become drier than the inside, which affects tang yuan quality. Let's go back to the case, the glutinous rice dough dried and cracked as dividing. ANKO's experienced engineer…(Please contact us to get more information)

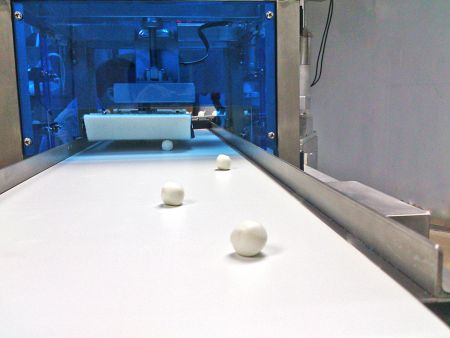

Simply prepare glutinous rice dough and lotus seed paste into hoppers of our machine manually, and then hand over the automatic production to the machine. The glutinous rice dough wraps filling and is divided into chunks in standard weight as required. The rounding process can be completed by ANKO's RC-180 Automatic Rounding Conveyor, which acts like human hand movement to make tang yuan not only tasty but also pleasing in appearance.

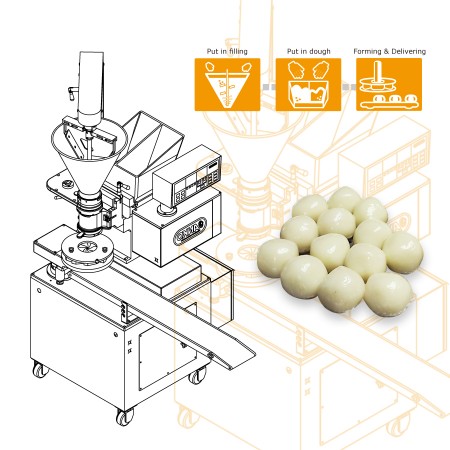

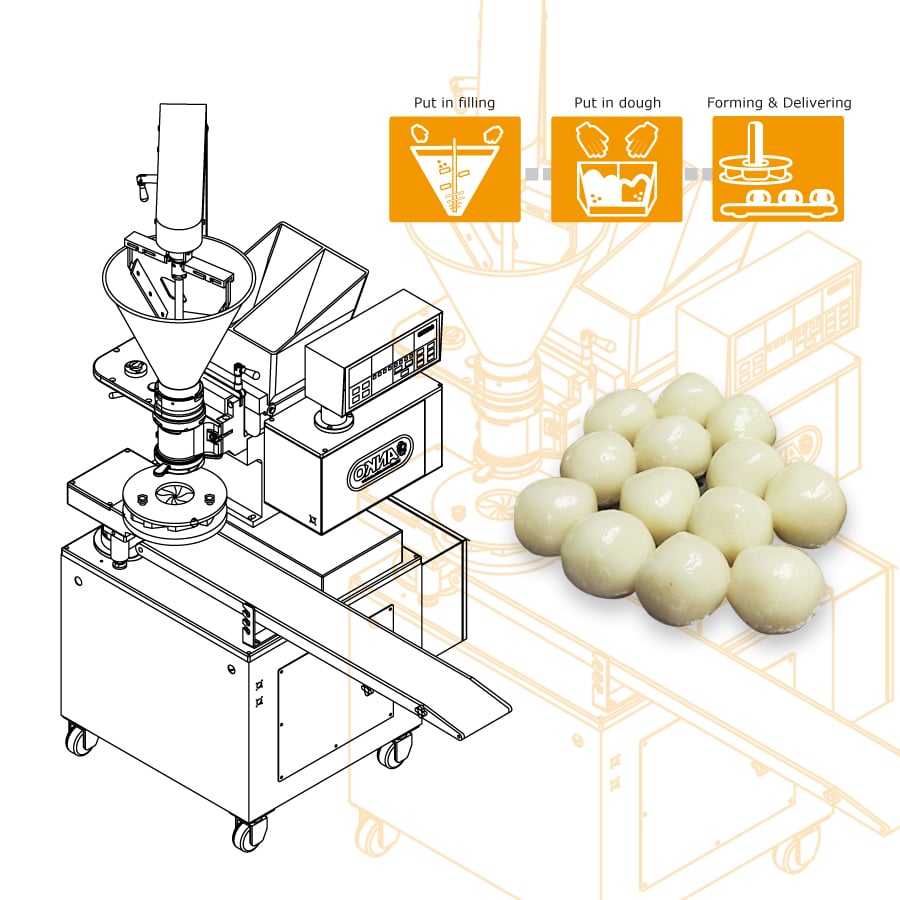

Food Equipment Introduction

- Mix glutinous rice flour and water.

- Put glutinous rice dough and lotus seed paste into SD-97W dough hopper and filling hopper, respectively.

- SD-97W automatically wraps filling in glutinous rice dough and cut it into equal chunks.

- Apply RC-180 to rub the filled glutinous rice chunks into ball shape.

- Boil or freeze lotus seed paste tang yuan.

The critical design feature of an Encrusting and Forming Machine

There are numerous encrusting and forming machines on the market today; they appear to be similar, but certain forming molds and clamps perform differently. The critical designs of a successful machine include the rate of forming and releasing of the molds and the material used for the specific mechanism. For example, some fixtures are designed to be in contact with the whole surface when they are actuated, and during production, the friction between the fixture and the mechanism is frequent and will require denser material. When ANKO designs our forming molds, we consider the contact area and evaluate the client’s product specifications to adjust parameter settings and production speed. ANKO has developed various forming molds, such as deep patterns, lighter prints, and other unique forming molds for client’s options.

- Solution Proposal

ANKO's Tang Yuan Production Solution Improves Productivity and Make High Quality Foods

ANKO did

Food companies seek to switch manual to automatic production, not only save time and reduce labor costs, but also speed up the manufacturing process. In this case, the client planned to produce Tang Yuan as their new product. ANKO offers corresponding equipment for them to meet their expectations.

ANKO can help you more

The Tang Yuan Production Solution includes mixer, filling and forming, rounding, packaging and food x-ray inspection machines to configure a One-stop Tang Yuan Production Line. Depending on your requirement, ANKO can customize an exclusive and comprehensive proposal. To ensure that the solution proposal is suitable for you, we can arrange a Tang Yuan production test run with our engineers.

For more information, please click Learn More or fill out the inquiry form below.

- Machines

-

SD-97W

This client ordered SD-97W with a non-patterned shutter to divide dough wrapped lotus seed paste into chunks with the production capacity from 1000 to 4000 pcs/hr. SD-97W is compact in size which enables you to install and clean with ease. With different shutters, it can make ethnic foods such as steamed buns, meatballs, mochi, cookies, etc. Fillings can be bean paste, peanut powder, minced meat, sesame paste etc for encrusting and forming without destroying its original flavor.

What's more, a Built-in IoT System monitors and manages all the manufacturing data which can quickly react to incidents and reduce technician troubleshooting time. It automatically detects the parts that require maintenance and sends alerts to ANKO Dashboard. This information can be easily accessed and will help to better manage maintenance and increase productivity and efficiency.

- Video

SD-97 Machine Operation Demo ─ It takes only one employee to load the dough and filling ingredients into separate hoppers, and the production can start after a simple click. The forming molds can be switched to produce a variety of food products. Standardized production is conducive to quality control and is highly recommended for commercial food businesses of different scales.

RC-180 Machine Operation Demo ─ After placing products on the conveyor belt of a RC-180, the machine can automatically round them at an hourly rate of 3,000 to 3,600 pieces. It is more efficient and consistent than rounding Tang yuan manually.

- Country

Hong Kong

Hong Kong Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Hong Kong with advanced automated food production technology for making Har Gow, Tang Yuan, and Glutinous Rice Ball (Mochi). We also offer integrated solutions for popular foods such as Dumplings, Shumai, Wonton, Dim Sum, Meatballs, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Chinese people eat tang yuan on winter solstice and the lantern festival. The custom has been handed down for a long time. Tang yuan and yuanxiao are often considered as the same food. However, traced back to the past, tang yuan is the name used in Southern China while Northern China called it yuanxiao. They are very different in dough's water content and recipe. Tang yuan wrapper is made from the mixture of glutinous rice flour and water and then wraps filling. In contrast, the filling of yuanxiao is firstly rounded by hand and put on a rice flour-dusting bamboo sieve. As shaking the sieve, filling balls are gradually coated glutinous rice flour so that yuanxiao contains less water compared to tang yuan. As time passes the difference between them is indefinite in the modern culture. There are two kinds of tang yuan, with or without filling. Smaller tang yuan has no filling while the bigger one with filling can be either sweet or savory.

- Handmade Recipe

-

Food Ingredient

For wrapper-Glutinous Rice Flour/Water, For filling-Lotus Seeds/Sugar/Oil

Making the wrapper

(1) Mix glutinous rice flour and water and knead them into dough. (2) Rub into long dough and divide into 15 equal portions. (3) Rub each one into ball, and then press it into flat circle.

Making the filling

(1) Soak lotus seeds for at least three hours. (2) Drain lotus seeds. (3) Put them in a pot and boil with water in high heat. (4) Turn low heat and keep boiling lotus seeds until soft. (5) Put softened lotus seeds and some water which just boiled seeds in a mixer to mash up them. (6) Add lotus seed paste in a pan to stir fry in low heat. (7) Add sugar and slowly stir fry until moisture dries up. (8) Add oil in several times, stir fry until oil dried up and then pour another spoon. (9) Turn off heat as lotus seed paste becomes thicken.

How to make

(1) Scoop lotus seed paste in the center of wrapper. (2) Wrap it up and rub the seal to form a round tang yuan.

- Downloads

English

English