Automatic Dual Line Imitation Hand Made Dumpling Machine - Designed for Spanish Company

The growing demand for frozen food and take-out food has led to intense competition in the Spanish frozen market. The client has run restaurants and sold frozen food to many supermarkets. Due to the expansion of the market, they needed a complete productivity solution that allowed new dumpling making machine to work well with their packing line and comply with food hygiene regulations. ANKO, as a solution provider, has many related experiences and the ability to customize machines, so they decided to cooperate with us. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

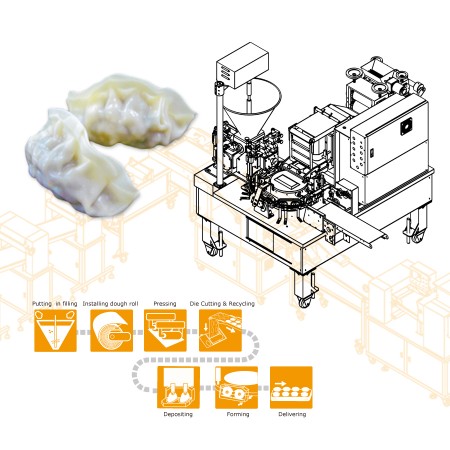

Steamed dumpling

ANKO Team Research Problem Solving or Solution Delivery

We provided a solution based on the client's packaging line to optimize production efficiency and save labor costs.

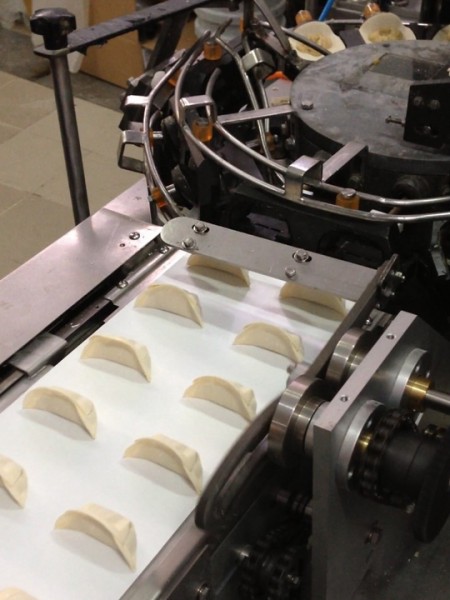

It is an important thing to balance automation system that includes automated and manual production in the field of factory management. In this case, the AFD-888 had the capacity of 7,000-9,000 pieces per hour, which become overload for packing line workers. Therefore, we customized division plates and installed another conveyor at the end of the conveyor of AFD-888. The added conveyor could increase the buffer time to prevent dumplings from dropping and the division plates were used for arranging dumplings neatly and uprightly, which could facilitate packaging and tray arranging.

The division plates and conveyor are installed to improve production efficiency

The division plates can organize dumplings in rows and in the same orientation as the dumplings are delivered from the conveyor of AFD-888 to the added conveyor. Also, the length and height of the added conveyor are customized to meet the worker's body posture to speed up packaging of tray arrangement.

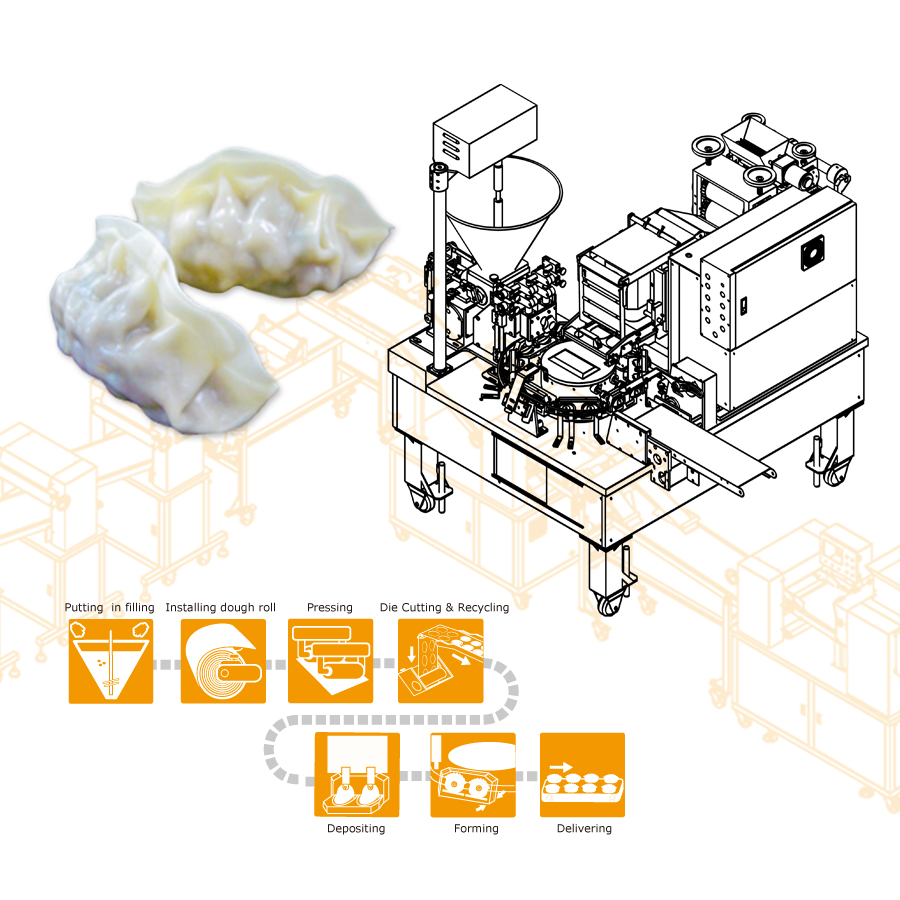

Food Equipment Introduction

- Put a dough belt roll, which is pre-pressed into 1.2 cm thick, on the rack.

- Put stuffing into the stuffing hopper.

- The dough belt is pressed into 0.1 cm thick by three sets of pressing rollers.

- The dough belt is cut into dumpling wrappers by a cutter, then fall on molds.

- The piston-type stuffing device deposits the stuffing on the wrappers.

- The pneumatic-driven open/close mold device seals the dumplings.

- The formed dumplings are pushed on to the conveyor.

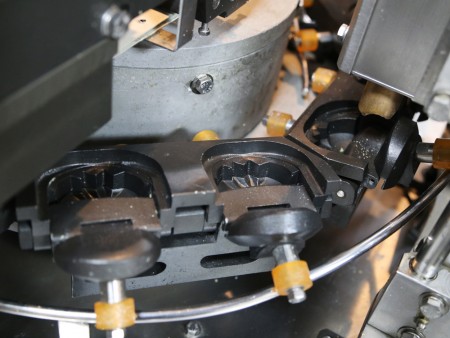

AFD-888 wraps dumplings with the pneumatic-driven open/close mold device and the PU pulley installed on the device performs the function of reducing mold abrasion.

The open/close mold device on AFD-888 is dedicated to wrapping stuffing. The dumpling seam can be sealed by the pressure of the mold easily because the dough contains a certain water to remain viscous.

It is worth mentioning that the PU pulleys with high hardness, good abrasion resistance, and high resilience not only help to generate the pressure driven by air cylinder to seal the seam tightly, but also can absorb shock as a buffer to reduce abrasion during mold closing.

Non-circular shape of wrapper creates distinctive dumpling appearance.

The dumpling wrappers are cut into a distinctive shape rather than a circle by ANKO Automatic Dual Line Imitation Hand Made Dumpling Machine. Although it is a nuanced difference, the dumplings wrapped by the non-circular wrappers have more attractive appearance with crimps and pleats.

In terms of R&D, the ingenious machine design contained a thinking process of what kind of wrapper shape can form the dumpling that is accepted by the market. Therefore, the look of finished dumpling is one of the reasons that AFD-888 gains favor with people.

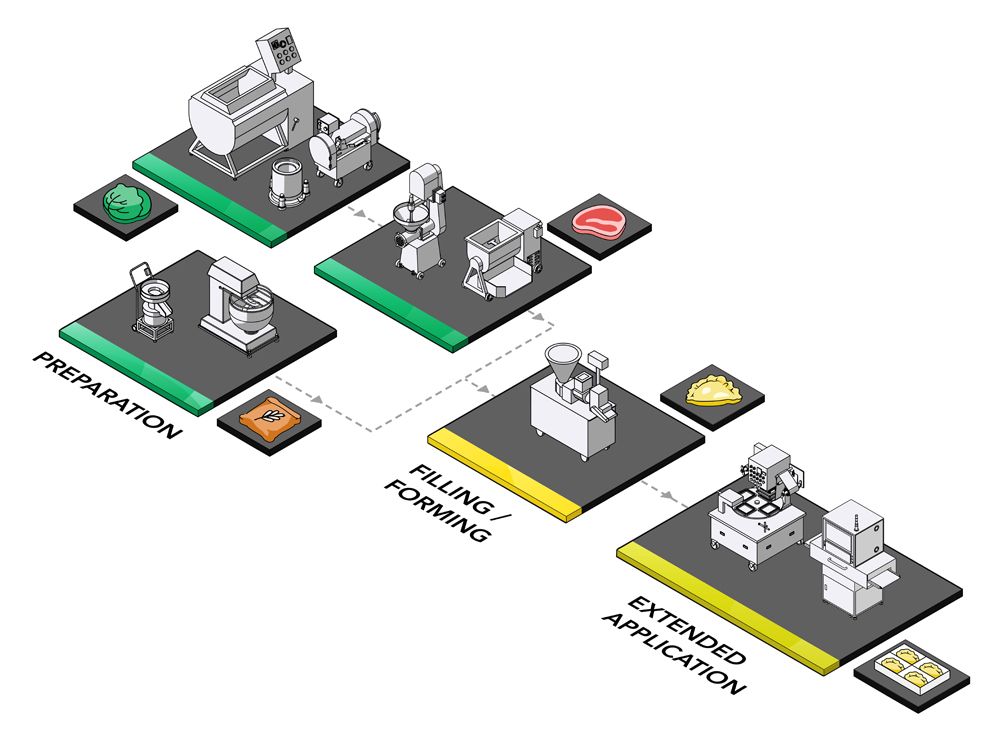

Processing Line Planning

- Sieving

- Mixing

- Vegetable Cleaning

- Vegetable Cutting

- Extracting

- Meat Mincing

- Seasoning

- Forming

- Sealing

- Solution Proposal

Tailored Steamed Dumpling Production Solutions to Meet Your Needs

ANKO did

ANKO not only provides food processing machines for food manufacturers but also offers custom solutions, turnkey planning, and one-stop services to meet your specific requirements and expectations. In this case, we supplied our Automatic Steamed Dumpling Machine to integrate with the client's packaging production line, enabling them to establish a standardized manufacturing process.

ANKO can help you more

Furthermore, ANKO can design a comprehensive Steamed Dumpling Production Solution that includes food preparation, filling and forming, packaging, and food inspection equipment. We tailor this solution to optimize your production flow according to your current situation and budget. For more detailed information, please click Learn More.

ANKO has a branch office in California, USA, and a network of agents and distributors across Asia, the Middle East, and Europe, ensuring timely support. If you're interested in our food solutions, please don't hesitate to reach out or submit an inquiry below.

- Machines

-

AFD-888

CE-certified AFD-888 Automatic Dual Line Imitation Hand Made Dumpling Machine is designed for producing dumplings based on the manual production process. All food contact surfaces are made of food grade materials. The pressing rollers and piston-type stuffing device can keep the texture of wrapper and stuffing. In addition, the recycling system is able to collect the rest of dough to avoid waste; meanwhile, the finished products are lined up on the conveyor in double rows to make collecting and packing easier. AFD-888 can produce 18-20 g, 24-26 g, and 28-30 g dumplings and has the maximum capacity of 9,000 pcs/hr. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

- Country

Spain

Spain Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Spain with advanced automated food production technology for making Spring Roll Wrappers, Gyoza and Dumplings. We also offer integrated solutions for popular foods such as Empanadas, Tortillas, Spring Rolls, Burritos, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Steamed dumpling, originated in China, is a kind of stuffed food with a long history, made with a thin wrapper stuffed with minced pork and shredded cabbage. It is usually cooked in a steamer with high heat and served with soy sauce. The steamed dumplings full of pork juices and with colors looming through the slightly translucent wrapper look so tempting.

- Handmade Recipe

-

Food Ingredient

For wrapper-Flour/Water, For filling-Ground Pork/Cabbage/Scallions/Sesame Oil/Salt/Soy Sauce/Pepper

Making the wrapper

(1) Add flour and water in a large bowl, then well stir them together. (2) Knead and press the dough with the palms of hands until sticky. (3) Rest for a half hour. (4) Dust the worktop with flour and knead the dough until smooth. Set aside.

Making the filling

(1) Chop cabbage and scallions and finely chop ground pork. (2) Mix them in a large bowl. (3) Add a dash of soy sauce and sesame oil and well stir the filling. Set aside.

How to make

(1) Roll the dough into a long, cylinder shape. (2) Equally divide the dough into small balls. (3) Roll out the dough ball into a thin wrapper with a rolling pin. (4) Spoon filling on the center of wrapper. (5) Smear water on the edge. (6) Fold it in half and tightly press the seam. (7) Pleat the edge. (8) Repeat last five steps to wrap all dumplings. (9) Cook them in a steamer.

English

English