ANKO's Wonton Machine successfully produces Wontons with a taste and texture resemble handmade products for a Canadian Company

The Canadian frozen food market is facing keen competition. Locals prefer ordering out or taking away food so as to save time. Ready-meal is also a choice for many families. In the client's chain restaurants, wonton soup is one of the most popular combinations. With the growing number of branch stores, they have to prepare more and more pieces of wonton every day. Therefore, they start using ANKO's wonton machine to automatically produce wonton, and then they freeze cooked wonton and deliver to every restaurant, which enable a rapid response to the increasing demand.

Wonton

ANKO Team Research Problem Solving or Solution Delivery

How to make it possible to produce pliable wrappers by machine to avoid frozen wonton from breaking after cooking?

Wonton is usually cooked and served in soup so that wonton wrapper should be soft and pliable to keep a smooth taste. Basically, HWT-400 was designed a built-in wrapper pressing unit which already delivered the solution of producing elastic wrapper. However, the client had a higher demand for wonton wrapper. Firstly, ANKO engineer tested ten recipes in order to increase gluten and evenly retain in a wrapper. He elaborately recorded the differences between ten recipes and the results to find out the best one to satisfy the client's requirement.

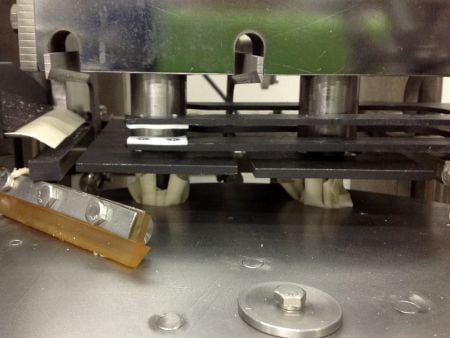

Secondly, considering not increasing costs, we employed the pressing device of……(Please contact us to get more information)

After testing ten different recipes, then we cooked wontons. The wrapper was not broken; even we held it by hand and shook it.

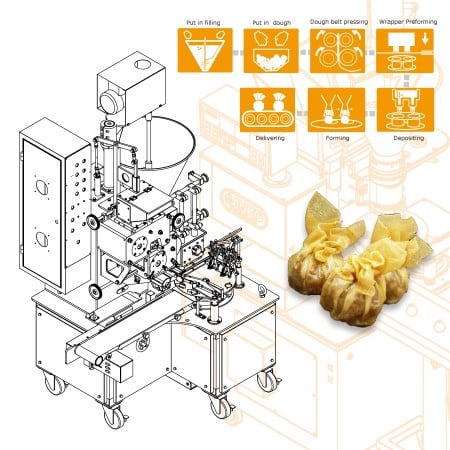

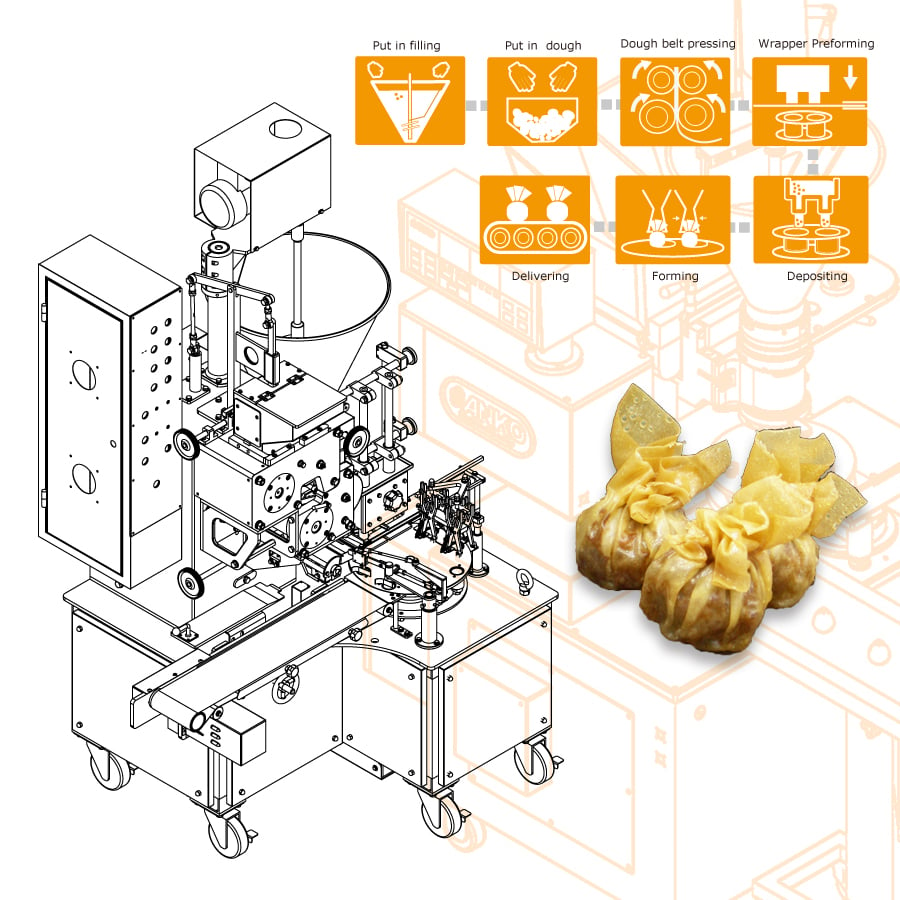

Food Equipment Introduction

- Pre-press dough into dough belt with a sheeter due to the client's requirement.

- Guide dough belt to HWT-400

- Tong dough belt and cut it into required size (within 90-100 mm).

- Punch wrappers into cylinder molds.

- Extrude stuffing into wrappers.

- Clip the top of cylindrical stuffing to pleat on wrappers and strengthen the tightness between wrapper and stuffing.

- Push final products forward onto conveyor.

The creative design of wonton machine

Wonton looks like a pleated sachet. Then, how can a machine produce products remained the artisanal character? To design a distinctive device is the key to pleat wonton wrapper on all sides.

- Solution Proposal

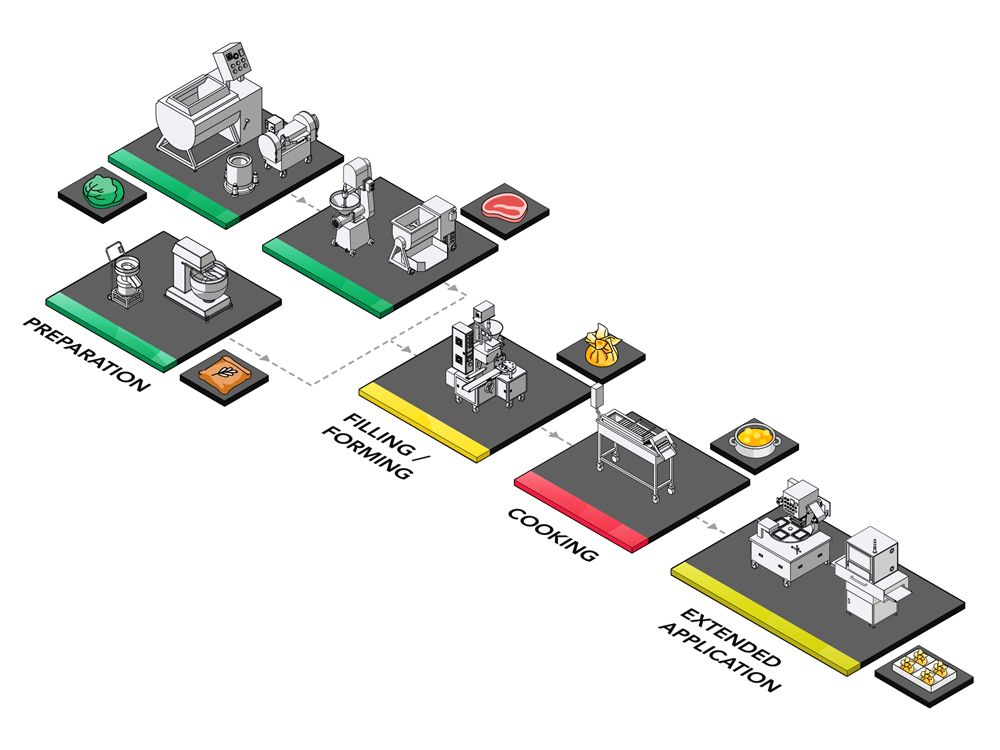

ANKO's Wonton Production Solutions to Help Your Business Grow

ANKO did

According to your conditions and production capacity, ANKO provides comprehensive Wonton Production Line setup from front-end and back-end equipment configuration, turnkey project planning, machine trial, installation to training.

ANKO can help you more

Also, we provide exclusive assessment and integration suggestions depending on current conditions, workflow, factory layout, estimated time to put machine into operation, recipes, and other issues. The integrated and specialist service can greatly reduce the risk of purchase and, to meet your requirements, give you the best solution to keep smooth operation anytime.

For more information, please click Learn More or fill out the inquiry form below.

- Machines

-

HWT-400

Stir flour into fluffy crumbs and then pour them and stuffing into hoppers, respectively. After that, automatic production of wonton begins from pressing wrapper, cutting, extruding stuffing to finishing products in one machine. The final products are neatly lined on the machine conveyor, which is very convenient for the client to pack and freeze, and then deliver them to restaurants or supermarkets. The built-in IoT system provides remote access to production status and real-time data and error reports to help managers quickly find and resolve problems. It also monitors the machine's health and maintenance schedule to extend its service life.

- Video

- Country

Canada

Canada Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Canada with advanced automated food production technology for making Spring Rolls and Wontons. We also offer integrated solutions for popular foods such as Empanadas, Samosas, Pierogi, Dumplings, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Wonton is a type of dumpling in traditional Chinese cuisine. It originates in Northeast China, usually cooking with noodles into wonton noodle soup. Compare to dumpling, wonton is consumed with soup while dumpling is eaten with dips. Typically, wonton wrapper is thinner than dumpling wrapper. As for wonton recipe, people mix minced pork, chopped green scallions and ginger and wrap them in square wrappers which feature thin and tender, soft and smooth and will not be mushy though cooking, remaining a pleasant taste. In the region of Canton, it is called wantan the filling of which includes shrimp or minced fish.

- Handmade Recipe

-

Food Ingredient

For wrapper-All Purpose Flour/Egg/Salt/Water, For filling-Ground Pork/Scallions/Ginger/Egg White/Water/Sesame Oil/Rice Wine/Salt/White Pepper/Corn Starch

Making the wrapper

(1) Mix flour, salt, and egg in a large bowl and stir well. (2) Add water while stirring the mixture until flour absorbs enough water. (3) Knead the mixture into a lump of dough. (4) Cover with cling wrap and rest for 10 minutes. (5) Knead the dough again until pliable and smooth. (6) Rest for another 30 minutes and cover with cling wrap. (7) Roll out it into 3 mm thick. (8) Cover with cling wrap and rest for another 30 minutes. (9) Take it out and cut in half. (10) Roll out one of them as thin as possible. (11) Cut out 8 cm square pieces.

Making the filling

(1) Cut ginger and scallions into thin strips. (2) Knead them in a bowl of water, then discard scallion and ginger strips. (3) Chop ground pork into sticky paste. (4) Add sesame oil, rice wine, salt, white pepper, corn starch, ginger & scallion water, and egg white into meat paste. Stir them well. (5) Scoop meat paste on a wonton wrapper. (6) Smear water on the edges. (7) Fold in half. (8) Moisten opposite corners of the long side. Fold toward each other and press the overlapping parts together to seal.

- Downloads

English

English