ANKO assisted a client in Spain to establish a Food Safety Certified Spring Roll Wrapper Production Line

The company is well-known in Europe, mainly selling Chinese food. They always take client's health as priority, so they stress that there is no artificial flavors and colorants, no additives, etc. and have the philosophy to strictly and carefully control their products for their consumers. Due to the business expansion, the client wished to increase productivity and find a food machinery supplier with high-quality machine and professional service. In 2006, they heard that ANKO provided high-quality, professional, and stable machinery that the philosophy of machine designing relieved the client. After that, they gave details of their requirement of productivity and local rules of food safety. For ANKO, we considered it's our job to meet their needs and provide comprehensive training and after-sales services so that their consumers can always enjoy safe, hygienic, and delicious food.

Spring Roll Wrapper

ANKO Team Research Problem Solving or Solution Delivery

In order to observe local regulations of food safety, how to appropriately plan the production line?

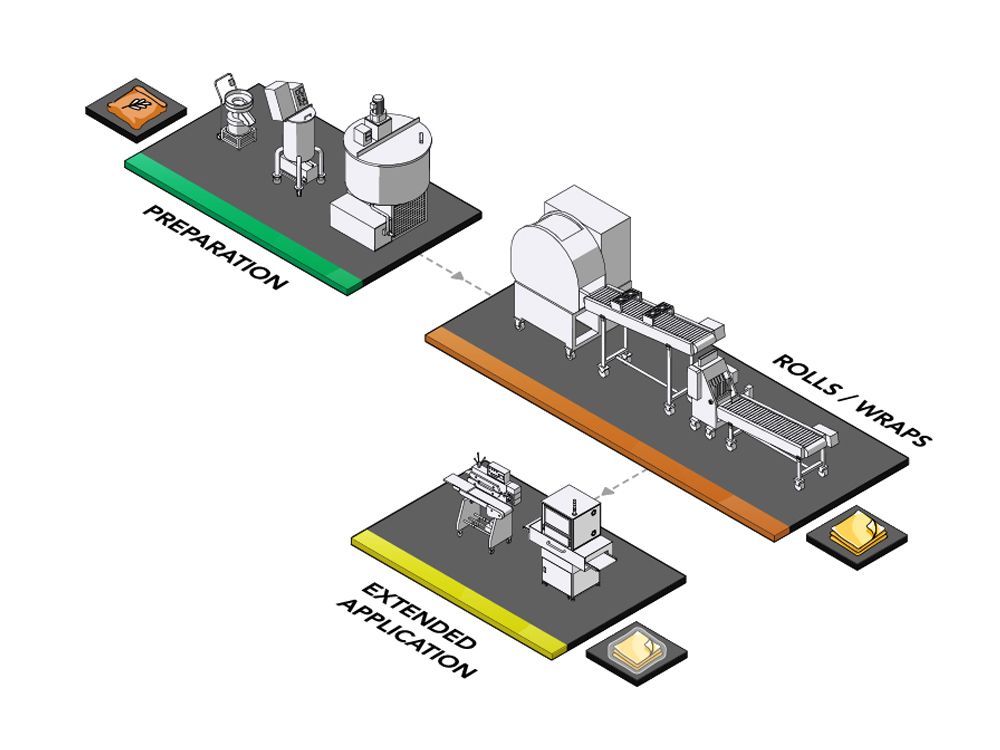

The client informed us that raw material processing and cooked food packaging should not be in the same space according to the law. Our spring roll wrapper production line combines culinary equipment, raw material processing, and cooked food packaging. Therefore, after estimating the current space, we suggested placing pastry baking drum in their kitchen and packaging line in the next space, separated by a light-gauge steel wall. Surely, we also customized the machinery in correspondence with changes. In the end, the client fully satisfied the solution we made.

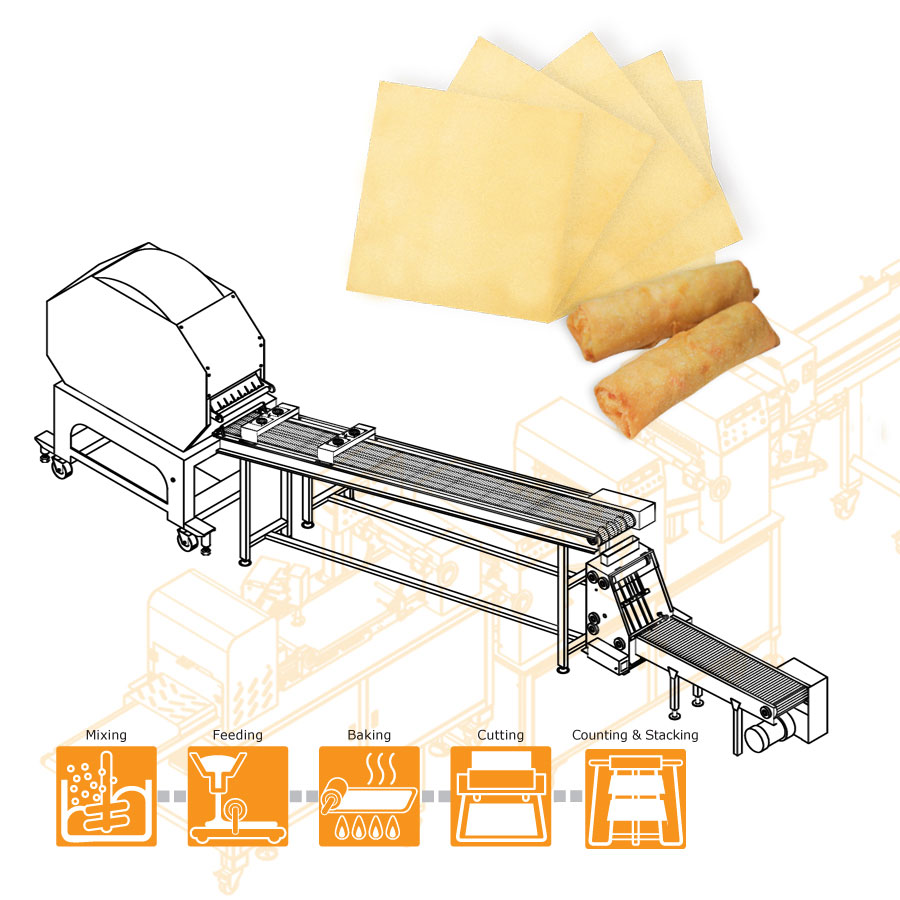

Food Equipment Introduction

- Well mix batter, and then pour into batter hopper.

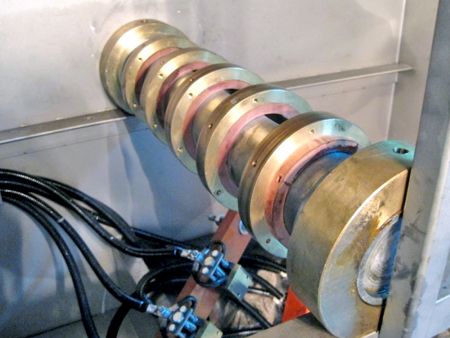

- Adjust control panel and check temperature and baking drum condition.

- Bake pastry.

- Cool pastry with fans.

- Cut into proper size.

- Stack cut pastry in piles.

Fundamental of Design

- The client had a requirement for increasing production capacity. Therefore, ANKO highly recommended SRP Series automatic spring roll and samosa pastry sheet machine, which hourly production rate is 2700 pieces.

- Machine parts and data are flexible to modify the size of spring roll wrapper. Further, the size of every machine-made wrapper is more identical than that of every handmade wrapper.

- Automatic stacking machine piles cut wrappers. Every pile will be delivered to the end of conveyor for wrapping by hand.

- SRP Series machinery is designed with an aim, which is the texture and taste of final products should be similar to handmade food. The client is highly concerned about not only food quality, but also stable producing process. Therefore, SRP Series is the one to make him provide the safest and best food to customers.

- Solution Proposal

ANKO Provides Industry-Leading Integrated Services In Spring Roll Wrapper Machines

ANKO did

To produce Spring Roll Wrappers efficiently, ANKO's SRP Automatic Spring Roll Pastry Machine is the best choice. Just pour the batter into the hopper, the machine can automatically produce Spring Roll Wrappers in thickness from 0.4 mm to 0.8 mm per sheet.

ANKO can help you more

Besides the Spring Roll Wrapper Machine, ANKO can also offer Batter Mixer and Batter Storing, Cooling & Resting tank, Packaging and Food X-ray Inspection Machine to improve front-end and back-end operations. The One-stop services allow you to save time for searching different machines. Based on our 48 years experiences, our professional consultant can offer customized Spring Roll Wrapper Solution to meet your requirement.

For more information, please click Learn More or fill out the inquiry form below.

- Machines

-

SRP Series Automatic Spring Roll And Samosa Pastry Sheet Machine

As pouring batter into the batter tank, it can be baked immediately at a high temperature through the baking machine, designed by ANKO R&D team. Then, the baked wrapper belt will be cooled at once, ready to be cut. The cutter unit is capable of cutting pastry automatically and, depending on parts and settings, the size of pastry is adjustable. Moreover, 2700-pcs-per-hour high productivity and standardized size products bring the client the greatest benefit as well as more delicious and high-quality spring roll. SRP machine can also produce crepe, samosa pastry, pastry for chicken salad roll, blini, blitzes, nalesniki, palacsinta, etc.

SR-24 Automatic Spring roll Machine

ANKO is always keeping pace with the diversified food market. Our RD team designs a flexible machine to produce many kinds of food wrappers through part changes and data settings. The brilliant design of extensible SRP Series machine is capable of working with other units to continue spring roll making process, that is, SR-24 Automatic Spring roll Machine. It stably produces products of good quality up to 2400 pcs/h. (The SR-24 is no longer available. The new model is SR-27 machine.)

- Video

Automatic Spring Roll and Samosa Pastry Sheet Machine Video - ANKO Automatic Spring Roll and Samosa Pastry Sheet Machine (SRP) is unique and the advantages of SRP are stable as well as high productivity. It is capable of producing not only spring roll pastry, samosa pastry, but also crepe, crepe with brown pattern, Blini, etc.

- Country

Spain

Spain Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Spain with advanced automated food production technology for making Spring Roll Wrappers, Gyoza and Dumplings. We also offer integrated solutions for popular foods such as Empanadas, Tortillas, Spring Rolls, Burritos, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Chun juan, or spring roll from ancient China, is a familiar food name to people in the world, but "chun juan" was named by the Han Chinese about hundreds of years ago. Traditionally it's made with a thin flour wrap stuffed with various vegetables, served on the day of "Lichun" (立春- start of spring) as a sign of auspicious. But nowadays, we can enjoy it at anytime and anywhere.

In general, there are two kinds of spring roll-deep-fried or fresh spring roll. The former is crispy while the latter is light and healthy. Stuffing and dip vary from region to region, depending on food cultures and habits.- Handmade Recipe

-

Food Ingredient

All Purpose Flour/Corn Starch/Egg/Water/Salt

How to make

(1) Beat egg and add some water to mix. (2) Add flour, starch, and salt and well mix them until dissolved. (3) Pour some batter on non-stick frying pan. (*Should not add too much batter because spring roll pastry is very thin.) (4) Spin the pan until batter covers the surface. (5) When batter gradually dries out, edges of pastry peel off. It is time to take a spatula and turn over the pastry. (6) Cook the other side in a few seconds, and then leave it at a plate. (7) Repeat the steps above.

- Downloads

English

English