ANKO Designed a High-Quality Automatic Sweet Potato Ball Production Equipment for a Taiwanese Client

The company is an actively developing food company, offering various sweet potato-based food products, including the popular shaved ice topping-sweet potato balls, and has been dedicated to promoting its brand and products with innovative ideas. A few years ago, they planned to make smaller sweet potato balls that can be added in drink. However, the machinery they had for making average-sized sweet potato balls could not produce such small ones. They found that ANKO has a GD-18B for making tapioca pearls. Afterwards, they visited ANKO for a trial and were satisfied with the machine and our services.

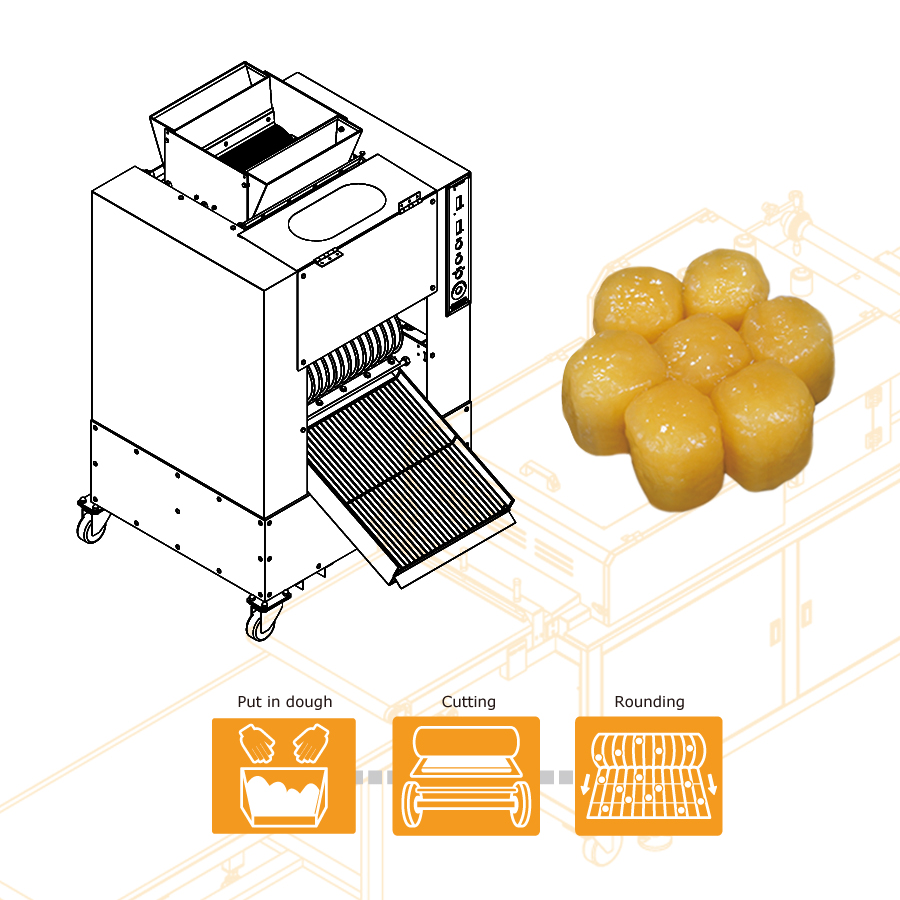

Sweet potato ball

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. How did our engineer and food researcher solve the problem that the sweet potato balls couldn't be formed?

The client visited us with a chunk of well-mixed dough. When our engineer conducted a test run of GD-18B, the sweet potato balls couldn't be formed. Our engineer and food researcher followed the SOP, trying to identify the problem step-by-step.

First of all, they found the dough might be too sticky. The client told them that the dough was made one day before they came to ANKO, so the dough was sticker than usual. Therefore, he agreed to add some starch to reduce the stickiness. Instead of solving the problem, it ended up not having stickiness at all. Our engineer suggested following our production processes……(Please contact us to get more information)

Consequently, our machine formed sweet potato balls as required and the taste was also accepted.

Solution 2. Secret to Perfectly formed Sweet Potato Balls

When hand-making Sweet Potato Balls or Taro Balls, it is crucial to sprinkle some flour onto the dough in the kneading, cutting, and various other steps to prevent the dough from sticking to your hands, working surfaces, and to keep the products in the right shape and form. When producing Sweet Potato Balls with an automated machine, this step is equally essential. ANKO’s machine has a flour dusting hopper that sprinkles flour onto the rollers and the dough to ensure the products are perfectly formed. Additionally, a CE cover can be added to the filling hopper to increase operational safety.

Food Equipment Introduction

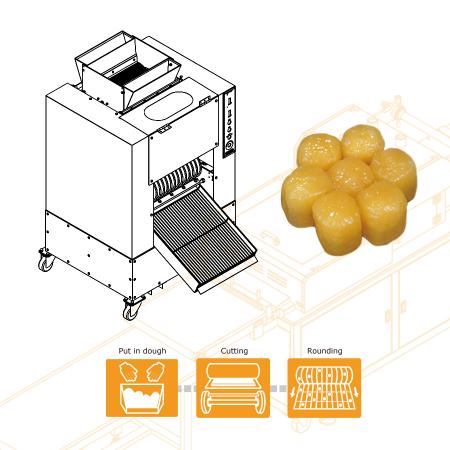

- Pour dusting flour into flour hopper.

- Put sweet potato dough into dough hopper.

- Adjust the speed of production.

- Forming rollers press the dough into a thick dough belt

- Cutting rollers cut the sweet potato dough into strips.

- The dough strips are diced and rounded into small balls.

Custom Rotary Cutting Rollers

The cutting rollers are different from the forming rollers, which are used to cut dough into strips and determine the product size. There are blades on the cutting rollers; the more the blades they have, the smaller the products will be. That is, the width of spaces between blades is equal to the size of products. Therefore, the cutting rollers are able to be customized, depending on the customer's product size requirements.

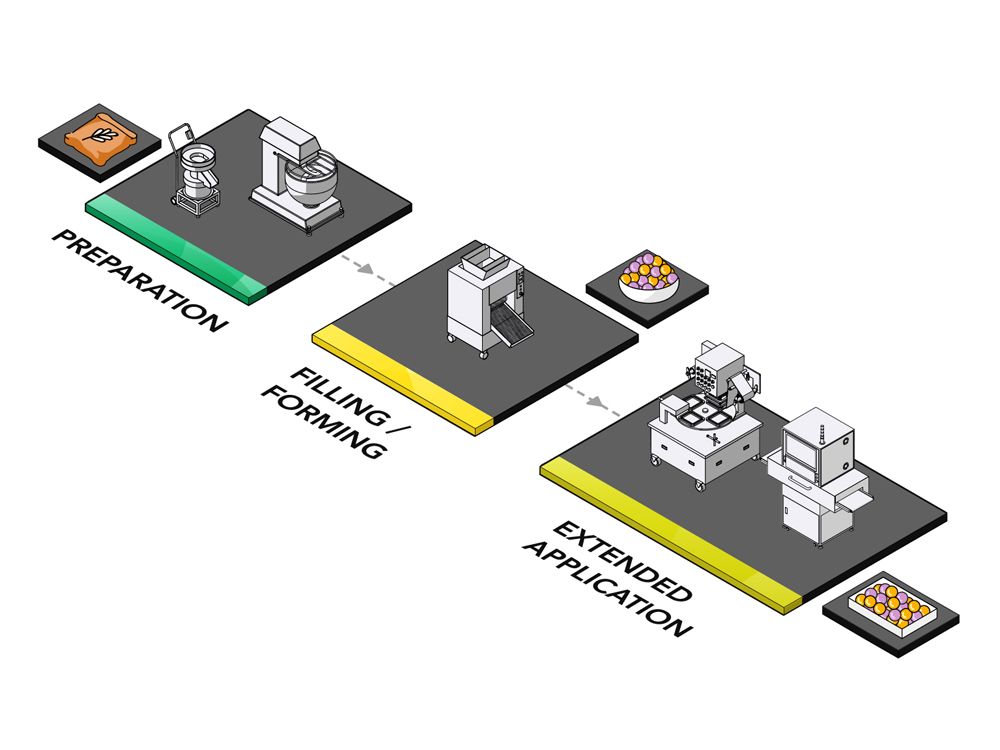

The key to New Successful Product Development: A High Quality Food Machine with Professional Recipe Consultation

ANKO’s GD-18B Automatic Sweet Potato Ball Production Equipment is designed to produce high quality Sweet Potato Balls; by using different recipes, it can also produce several different products such as Tapioca Pearls, Tangyuan (Sticky Rice Balls), Tapioca, Taro Balls, and Fish Boilies. In this case, ANKO’s client has already been producing Taro Balls for their business and were interested in the potential market for Tapioca Pearls. This customer was completely satisfied with the different types of products ANKO’s GD-18B can produce.

- Solution Proposal

Start a Profitable Food Business with ANKO

Are you considering transitioning your food production from manual to fully automated processes? Or perhaps you're looking to automate a new product but unsure how to proceed? ANKO has a fully equipped Food Lab, ready to assist with recipe optimization, new product development, and turning your idea into profitable businesses.

ANKO GD-18B machine is designed for Sweet Potato Ball production can create various other popular food items like Tapioca Pearls, Taro Balls, Tang Yuan, and more. Its compact size makes it ideal for drink and dessert shops. For larger-scale food factories and central kitchens, we recommend incorporating additional equipment such as a dough mixer, packaging machine, and food x-ray inspection machine to significantly enhance production efficiency. Please click Learn More or fill out the inquiry form to discover more details.

- Machines

-

GD-18B

The GD-18B production processes, involving dusting, pressing, cutting into strips, dicing, and rounding, are designed based on the manual production processes, in order to ensure the look, taste, and texture of the final products resemble the handmade ones. The rollers of GD-18B are made with stainless steel, rather than aluminum alloy -the material oxidizes easily and may affect the durability of a machine and food safety. GD-18B can process 25 - 180 kilogram starch dough per hour and the product size ranges from a minimum of 0.8 centimeters to a maximum of 2.0 centimeters.

- Video

How does ANKO's Automatic Cutting and Rounding Machine work to make fresh sweet potato balls, taro balls, tapioca pearls, tang yuan, etc.? At the beginning of the video, flour has been dusted on the rollers to prevent starch dough from sticking to the rollers. Then, put the starch dough into GD-18B. The machine is able to automatically press dough, cut dough into strips, dice and round small pieces into balls. The video also shows the cutting rollers that can be customized according to food size requirement. Moreover, a product slide mesh is installed at the exit to collect and sift out final products in required size.

- Country

Taiwan

Taiwan Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Taiwan with advanced automated food production technology for making Dumplings, Potstickers, Noodles, Shumai, Scallion Pies, Steamed Custard Buns, Tapioca Pearls, and Sweet Potato Balls. We also offer integrated solutions for popular foods such as Baozi, Wonton, Spring Rolls, Pineapple Cakes, Xiao Long Bao, Tang Yuan, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Sweet potato balls are a popular topping for different kinds of Taiwanese traditional dessert such as shaved ice, Chinese soy pudding (douhua), and herbal jelly. They are made of the mixture of steamed sweet potato, tapioca flour, and some sugar, then boiled and chilled into little springy and slightly chewy pieces. Due to the prevalence of bubble tea, some beverage store owners make sweet potato balls as small as tapioca pearls so that people can enjoy the taste of sweet potato as drinking milk tea.

- Handmade Recipe

-

Food Ingredient

Sweet Potato/White Sugar/Tapioca Flour

Making Sweet Potato Balls

(1) Cut the sweet potato roughly into pieces and steam them until soft. (2) Add sweet potatoes, white sugar, and tapioca flour in a large bowl. Then, stir the ingredients well to combine them. (3) Dust flour on the worktop and knead the mixture into a ball. (4) Divide the ball into equal portions and roll each piece into a cylinder. (5) Cut each cylinder into bite-sized sweet potato balls.

- Downloads

English

English