Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

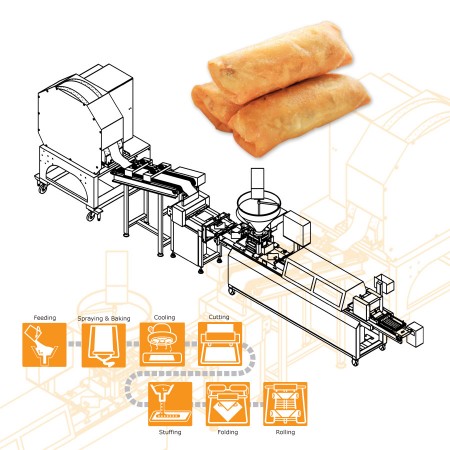

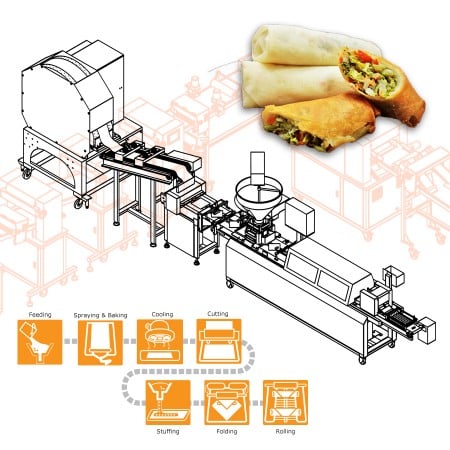

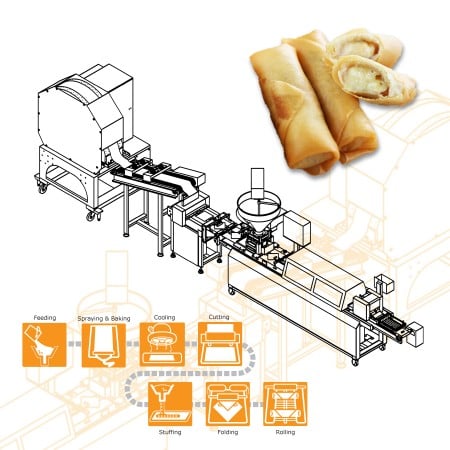

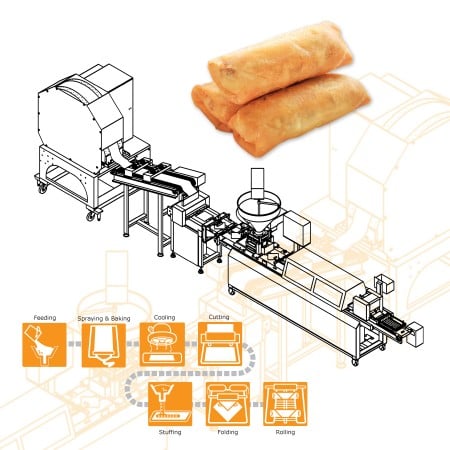

The client's products are Halal food, including spring roll with vegetable stuffing, chicken and onion stuffing, cheese stuffing as well as beef stuffing, permissible for Muslims. At the end of Ramadan, fasting was not required. It was the time for people to go shopping and buy food; as a result, the client received a large number of spring roll (cigar roll) orders. He uses three semi-automatic spring roll production machines, which need employees to wrap rolls by hand. Anko machines are satisfying for him. For the reason, the client considered to order a new spring roll machine with special folding and rolling device, in order to reduce labor costs, increase capacity, and control the quality of standardization. (The SR-24 is no longer available. The new model is SR-27 machine.)

The client already has a spring roll processing machine from other company. Since his business grew, he would like to increase productivity and improve the looks of products. He had been looking for a better solution, also an acceptable price. Finally, ANKO gained favor with the client. It's not only because the machine itself, but our competent team. We have abundant knowledge in food ingredients and recipes; We have years of experience to determine the effect of any conditions, such as temperature, water temperature, pneumatic equipment, or electrical equipment on machinery and food; and last but not least, our engineers are full of passion to find every possible solution. (The SR-24 is no longer available. The new model is SR-27 machine.)

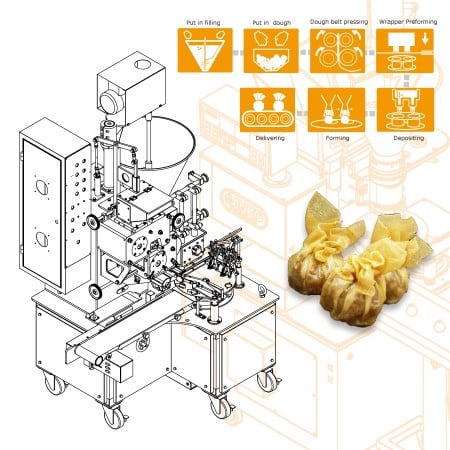

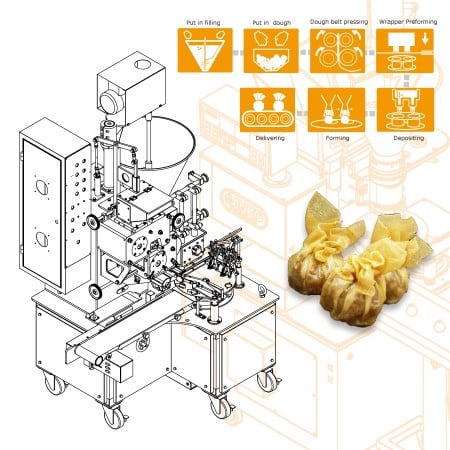

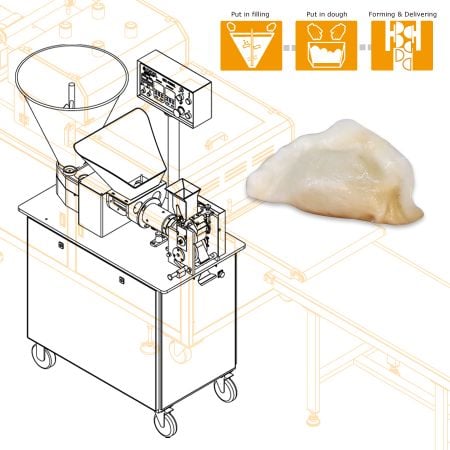

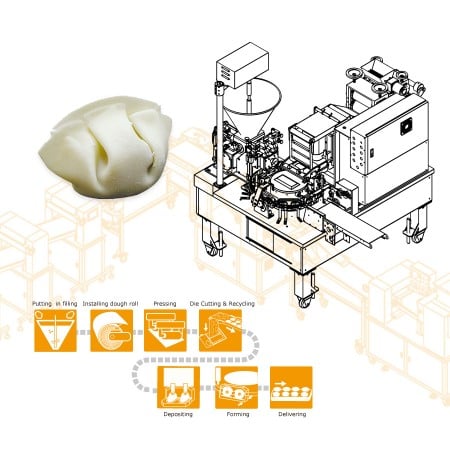

The Canadian frozen food market is facing keen competition. Locals prefer ordering out or taking away food so as to save time. Ready-meal is also a choice for many families. In the client's chain restaurants, wonton soup is one of the most popular combinations. With the growing number of branch stores, they have to prepare more and more pieces of wonton every day. Therefore, they start using ANKO's wonton machine to automatically produce wonton, and then they freeze cooked wonton and deliver to every restaurant, which enable a rapid response to the increasing demand.

The client produces a wide range of products from dairy products, frozen ready meals to bakery. They are also devoted to customizing innovative foods. Various flavors and delicate appearances are superior to other competitors' products. However, the frozen food market changes all the time. How can the company strictly control costs while guaranteeing capacity and quality? The knack is the combination of machine-made and hand-made processes. They do not just sell unchanged products but garnish foods and vary flavors to surprise consumers. The combined processes not only save time and costs, but also turn the impression of uninteresting products made by machines. It is our pleasure that ANKO's machinery was chosen to shape their basic products, which means that our efficient and high quality machinery gains favor with the client.

The client begins business by manufacturing seasoning. Up to now, the company has been established for more than one hundred years, providing delicious, health, and safety food to gourmets. Since their dim sum products are on the market in 1990, they have applied ANKO's stir fryers (SF Series), dumpling making machines (HLT-700 Series), spring roll production line (SR-24), semi-automatic spring roll production line (SRPF Series) to produce and sale frozen foods, including Chinese fried rice/noodle and various kinds of dim sum, in many countries. With the growth of demands, the supply of Har Gow (Shrimp dumpling), made by hand, was unable to meet a large number of orders. This client still purchased an automatic dumpling machine with Har Gow (Shrimp dumpling) forming device from ANKO because they believe in our machine quality, which achieves the client's ideas with regard to strictly maintaining sanitary environment, controlling every production process, and providing the safest food to consumers.

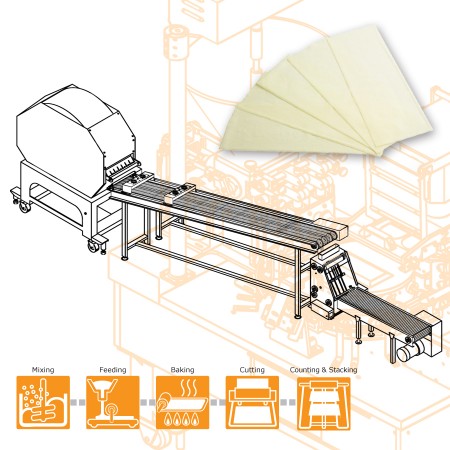

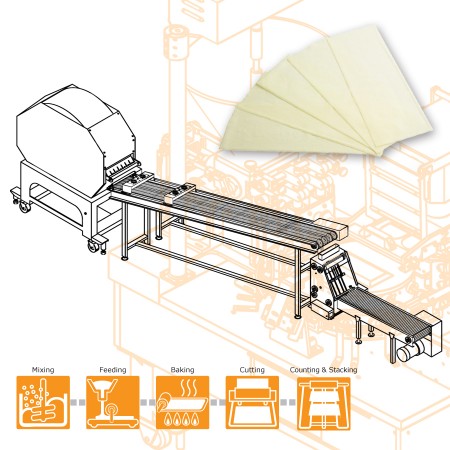

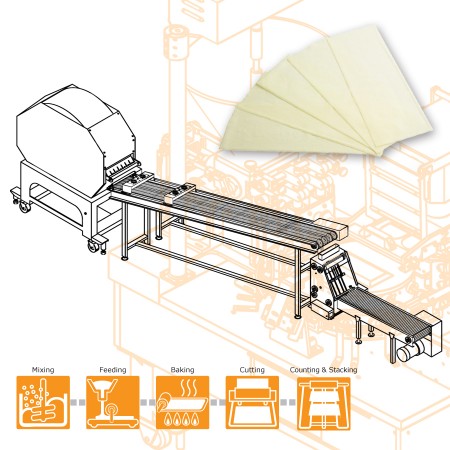

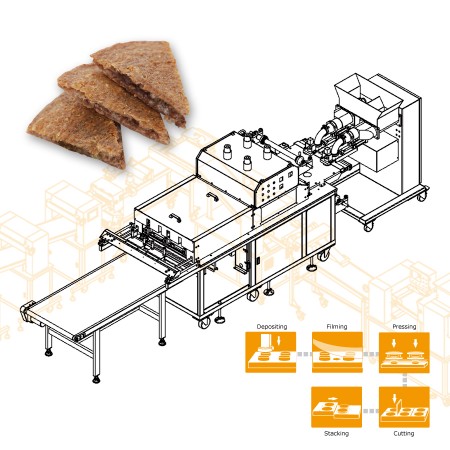

This ANKO client is a well-known food producer and supplier in India, their frozen food and baked goods are widely distributed throughout the country. Samosa is a popular staple; it can be served as street food snacks, and they are also a key part of festive celebrations. Islam is the second largest religion in India, and Samosas are always in high demand during Ramadan. Therefore, this client was in need of professional commercial food machines that can produce high quality products in large quantities to meet the market demand. The machines they found locally could not meet their product requirements, so they contacted ANKO. Subsequently they visited ANKO’s headquarters in Taiwan. After testing ANKO’s machine with production trials, our professional teams provided many production solutions, and the client was very satisfied with our Samosa Pastry Sheet Machines.

The company's cheese roll features its thin pastry made of batter. Compare to Chinese spring roll, they are quite similar in the handmade production and crispy taste. This cooperation is not the first time. The client had bought our other machine types and was satisfied with their quality and productivity. This time, through our customized services and trials, we followed his recipe and successively produced cheese rolls via our cheese spring roll production line. Therefore, he still purchased our machine without hesitation to meet growing demands. (The SR-24 is no longer available. The new model is SR-27 machine.)

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one, striping pastry. The complex process spends a lot of time and labor costs. ANKO's Samosa Pastry Sheet Machine can hourly produce 16,200 pieces of samosa pastry with standard size and automatically stack in piles. Also, the thickness is adjustable as desired. That results in considerable saving in labor costs. In addition, the machine can produce both spring roll pastry and samosa pastry which helps the client develop a new product line and bring business opportunities. The investment is of great worth, relatively.

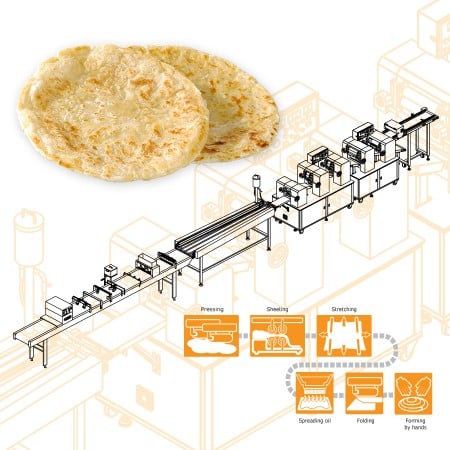

The client is a frozen food manufacturer, producing Indian food and selling to grocery stores and supermarkets. The growth of demand for paratha urges the client to seek automatic production line so as to reduce labor cost and increase productivity. The texture and taste of lachha paratha is layered and crispy that ANKO R&D team understands and keeps the characters in machine-made products. Our machine is capable of stretching dough to be pervious to light as well as producing products up to 2,000 pieces in one hour. The client satisfied those advantages of the machine so that they decided to cooperate with ANKO. (Note: LAP-2200 is no longer available. The updated model is LAP-5000. Please feel free to contact us for more information.)

The client runs a bakery group whose divisions are present in many countries of the Middle East and Asia. They form a complete supply chain, including farms for providing raw materials, industrial bakeries for processing food, and numerous retail bakeries and agents. They implement quality control strictly to ensure that products remain their best quality as delivering to consumers anytime. With the business expansion, the client was proactive to find a food machine supplier who delivers not only good quality machine, but also professional after sales services. In 2000, they received information about ANKO's spring roll machine which can produce good quality samosa pastry as well. Such a multipurpose and cost-saving machine was the reason that they decided to cooperate with ANKO. After using ANKO machine for 10 years, due to the stability of the machine, we won their trust. They have ANKO in mind and believe we could help them further expand other new product lines.

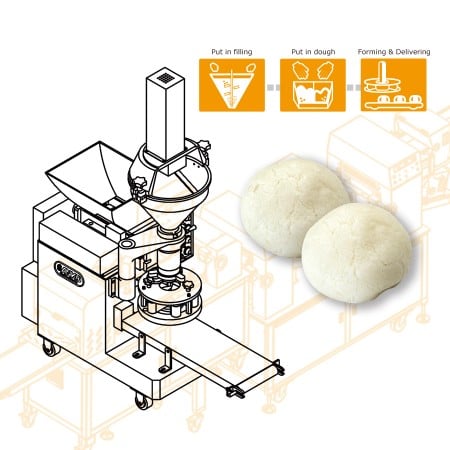

Vegetarian foods are the client's primary products. The manual production no longer meets the growing demands. For that reason, automation is what they need to boost capacity and profits.

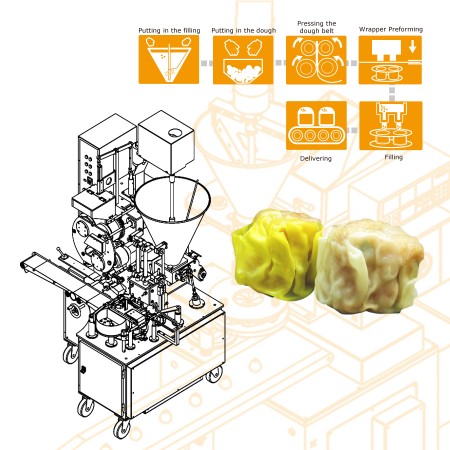

The client has a central kitchen to produce and sell shumai to retailers and takeaways. The growing demand and labor costs prompted him to find an automation solution. Through his friend's introduction, he knew that ANKO is a professional food machine manufacturer. When he visited us for machine test, we used radish shreds in substitution for cassava shreds because cassava is not common in Taiwan. It's also an unprecedented attempt for us. Finally, we were glad to succeed in producing radish shumai by our shumai machine and earned recognition from the client.

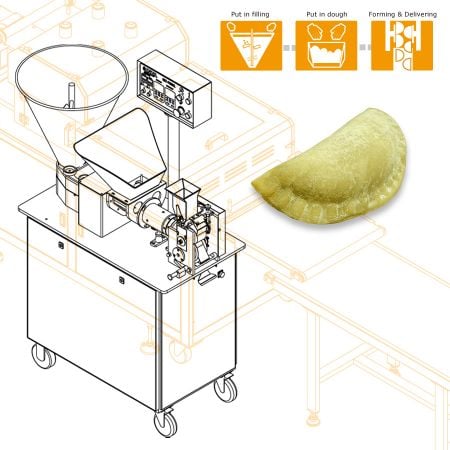

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors and got great comments on some travel websites. The calzone, both its recipe and ingredients, is handmade by their chef. As spending holidays in the hotel, tourists can buy a portable calzone at a concession stand and enjoy it as leisurely walking around. Due to the widespread reputation of the dish, they decided to buy a machine to meet the growing demand or the future launch of new menu in their restaurants. Then, the gourmet calzones could be produced in their central kitchen and distributed to each restaurant, which not only maintains product quality, but also cuts the labor cost.

The manual production of Kubba Mosul Pastry relies on a large amount of labor. The ingredients for making pastry and filling must be prepared separately; in addition, shaping a flat circle takes complex steps. Many Middle Eastern immigrants in western countries cannot forget the taste of hometown. Therefore, the market not only in Middle East but also in western countries, there have been marked growing needs for the manufacture of many Kubba Mosul products. A lot of clients hoped to have an automatic Kubba Mosul machine, so that ANKO has kept that in mind and carried out the new project development.

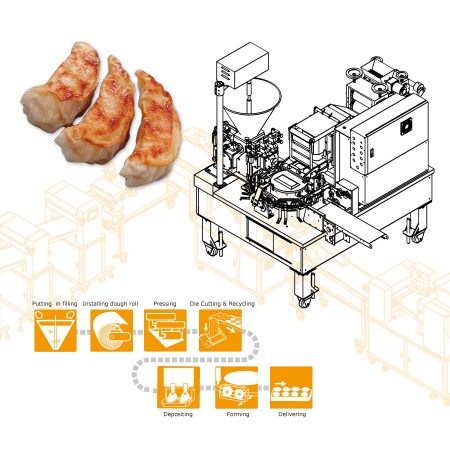

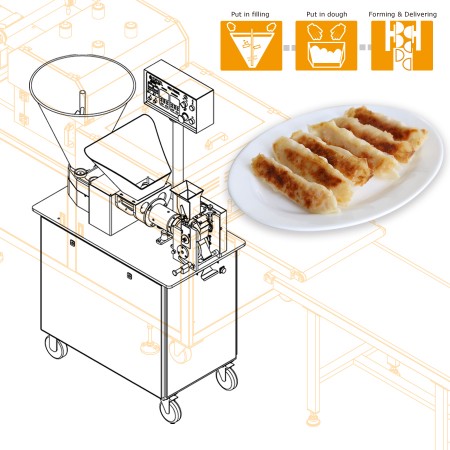

The client, one of our old clients, purchased ANKO's Hargao Forming Machine and Fish Ball Machine. He not only is an OBM of frozen food products but also supply OEM service. In Spanish frozen food market, gyoza was rather new to locals. However, the client was brave expanding an all-new production line on the strength of the well-known brand he created. He hoped gyoza, a dish represents Japanese culture, could be served on the tables in Spain. In order to develop a complete new project, the choice of machine supplier shall be more careful. The client had a pleasant experience of cooperating with us so that he was confident that we were able to plan a whole production line, including machines for preparing ingredients and cooking products such as a steamer, etc. About the gyoza making machine, we recommended him AFD-888, it is with a closing mold device which can produce springier yet firm in taste and more delicate in appearance. The whole project was well prepared and ready to hit the market. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

The client runs a vegetarian food processing factory with HACCP as well as Halal certification. Hundreds of vegetarian food products are manufactured by the company and exported to Singapore, Australia, and other countries. With the new online shopping site, they received more orders than before, so that they planned to replace high-cost and low-efficient handmade production with automation. The client has ANKO's Automatic Spring Roll and Samosa Pastry Sheet Machine already that has been smooth without lagging, as a result, they trust in our machine quality. In this case, the client would like to produce two kinds of siew mai with one machine. One is dough wrapper; the other one is tofu skin. Both they and we wondered whether the innovation of tofu skin siew mai could be made by the same machine. The client would like to have a try because we are the only company who offers testing service.

The client operates an air catering company. They offer airline meals to many flights for serving tens of thousands of passengers who travel in and out of China. Shrimp dumpling is an exquisite dish just for business and first class passengers. Due to its complex procedure, rising wages in China, and growing demand, they decided to automate the production of shrimp dumpling. ANKO's Automatic Har Gow Forming Machine manufactures 2,000 pieces per hour and delivers standardized quality control, stable production, simple maintenance and care. They are key factors that contribute to the cooperation.

The client runs an eatery next to a school. Two people in total have to be in charge of all works. Due to the fact that more and more people patronized the eatery, the labor shortage prompted him to develop machine production. However, high productivity was not his priority so that he ordered a set of HLT-660 series, which is within budget and enough to achieve his hourly capacity around 5000 pieces. After purchasing the machine, they prepare ingredients in the morning and then arrange production around noon, cooking after taking an order, which can satisfy a large demand during peak hours. (Note: HLT-660 series is no longer available. Please contact us for the updated HLT-700 series.)

The owner purchased our HLT-series, PP-2, SD-97, SRP, and Automatic Maammoul and Moon Cake Production Line, full of confidence in ANKO's machines. After that, he decided to buy two spring roll production lines (SR-24) at a time, because it produces high-quality and uniform products and can be used in combination with the existing SRP-series to manufacture either pastry or spring roll. It is a massive and wise investment. (The SR-24 is no longer available. The new model is SR-27 machine.)

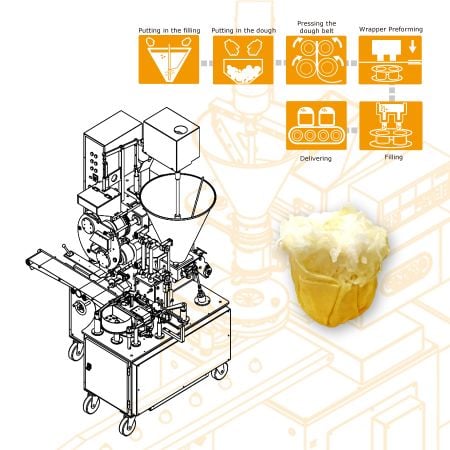

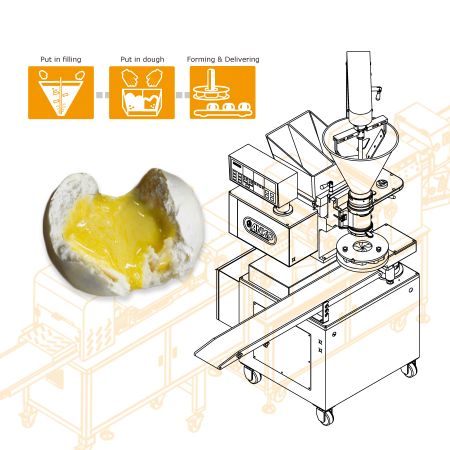

The dining group operates Cantonese restaurants, hot pot buffets, and Japanese buffets for satisfying various consumers. They used to make their food products by hand. With more and more restaurants opened, the continuing growth in demand for steamed custard buns in all types of their restaurants prompted the company to invest in a new machine to extend its offerings. it's a turn to transform handmade into automatic production. Chefs hoped to maintain food quality while cutting cost so that they found ANKO. We have the largest market share in Taiwan food machine industry and our machine can help them meet the growing demand. After testing our SD-97W, they are satisfied with the multifunctional encrusting and forming machine which offers them the flexibility in production. In addition to steamed custard bun mentioned above, they also use the machine to produce sesame balls.

The client began his business from running a dim sum restaurant, introducing the taste of Chinese cuisine to the Dutch and developing a health-oriented menu. With the growth of business, they established a food processing factory. As looking for equipment, they found that ANKO has years of experience in the field of food equipment and customizing machinery on the basis of individual needs and factory space. Therefore, he decided to cooperate with us. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

The Indian British brothers own two dessert shops. For cutting cost, they went to a machinery show and got much of an impression of ANKO. Through simple communication, they decided to come to Taiwan for a test-run. In addition to traditional ball-shaped rasgulla, it's successful to produce circular shape and long shape with shaping devices. Due to our quick and comprehensive services, the clients ordered two sets of machines for each dessert shop.

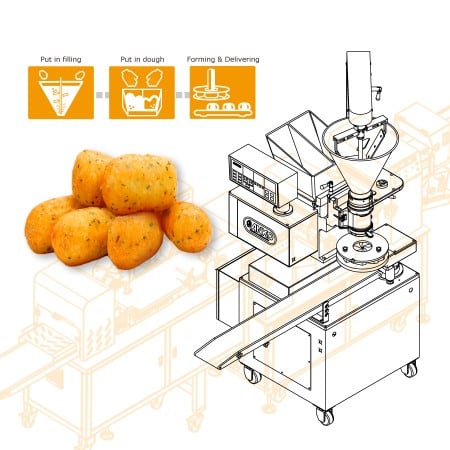

The Peruvian client is the boss of a restaurant and food factory. Our business relationship began with a compact vegetable cutting machine. As he found that ANKO's soft power in research and development as well as abundant recipes, we have become one of his consultants for solutions. The client's stuffed cassava products had been made by hand. When the demand increased to a certain amount, he was seeking a machine that provides labor saving and productivity boosting solutions. In order to ensure product quality, he came to our central kitchen in ANKO headquarters for a machine test run and face-to-face communication with our engineers regardless of the great distance. It's all for the best wrapper/filling ratio and the most appropriate recipe for automatic production.

The long-established North China cuisine restaurant is owned by a veteran emigrating from China. Its signature dish --potsticker--is many people's all time favorite, as a result, the supply was often unable to meet the demand. Then, they decided to manufacture potstickers with machine and took the opportunity to improve the appearance of their potstickers. In the end, they found ANKO because we offer customization services and project solutions. The project was totally different from the development of other standard potsticker making machines. During the period of research and development, we'd tried potstickers with both-end-open, both-end-close, different sizes and types of sealed ends as well as given them many professional suggestions patiently. Finally, the customized forming mold for making both-end-close potstickers and the final products satisfied their needs and gave them more confidence in boosting sales in the future.