Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

FilipinoTo increase food production capacity and expand food product line are the main reasons that food factory owners contact ANKO. We helped them switch from manual to automatic food production, design food factory layout, optimize food production process, and modify recipe.

With the growth of demand, ANKO's value is to help clients increase efficiency and seize food business opportunity through our food production solutions.

You can find more successful cases that have helpful food solution information you need below or send an inquiry to us now!

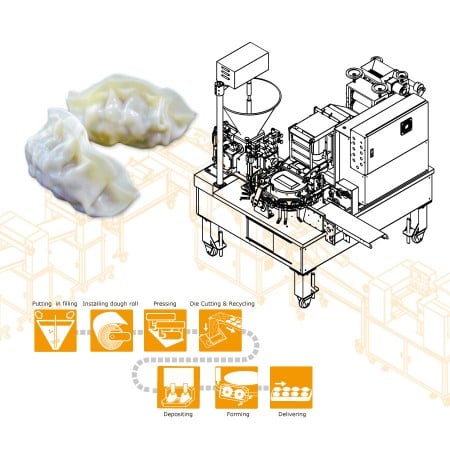

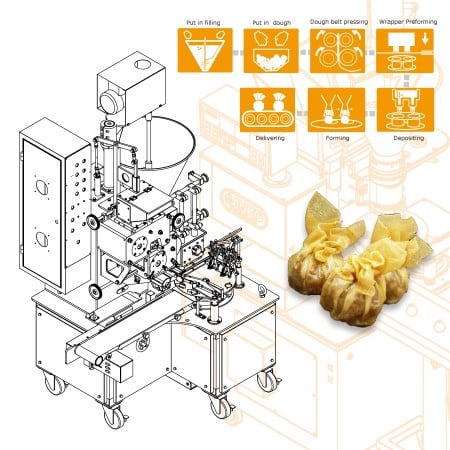

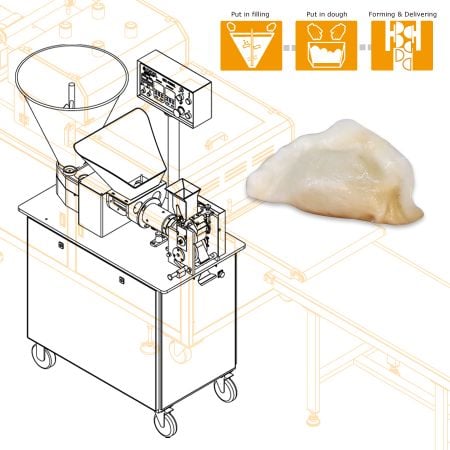

Due to high labor costs and employee management issues, the client, specialized in making Chinese food, started to look for a food processing line for making fried and steamed dumplings. A friend recommended ANKO Food Machine Company to the client. With dumpling making equipment operates automatically, the client is able to increase their production amount with better management. In addition, AFD-888 with CE certificate meets the client's necessary requirement- food safety and hygiene. It is the most important reason that the client chooses ANKO. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

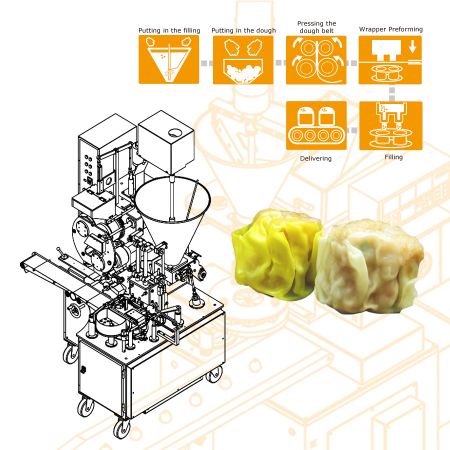

At the restaurant, you see packs of people having their traditional Chinese food, dim sum, in Hong Kong. Dim sum has been a major meal for Hong Kong people. With increasing restaurant business, the owner of a dim sum restaurant would like to expand his production capacity with the tight kitchen space. Quotes from many food machine suppliers were higher than the owner's budget. Only Anko provided reasonable price and excellent quality. ANKO is a food making machine supplier with over 48 years of experience and their solid reputation attracts the owner to ask for their turn-key project solutions.

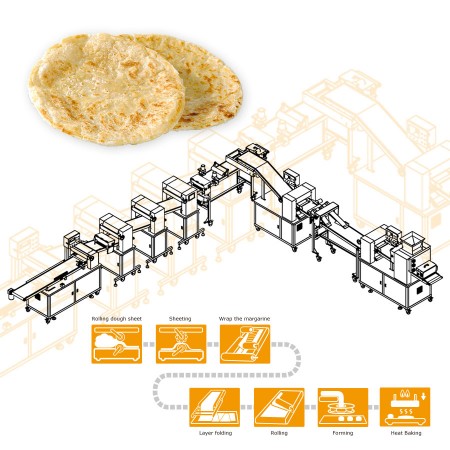

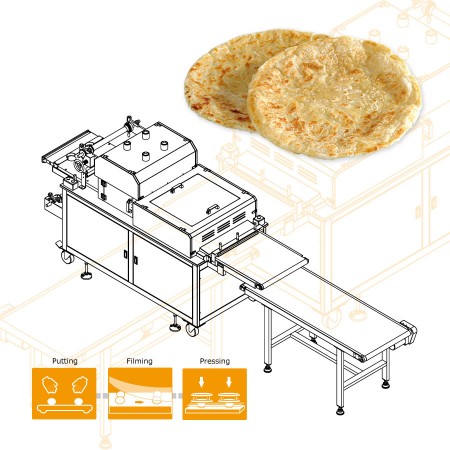

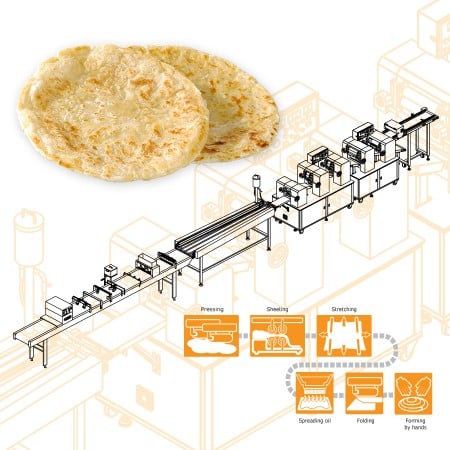

This company is a food supplier that specialized in providing frozen prepared foods in India. They contacted ANKO for food processing equipment solutions due to increasing demands. The quality, weight, and size of the handmade paratha aren't consistent and the production capacity is low. It would therefore be a total solution if paratha production equipment can solve all problems.

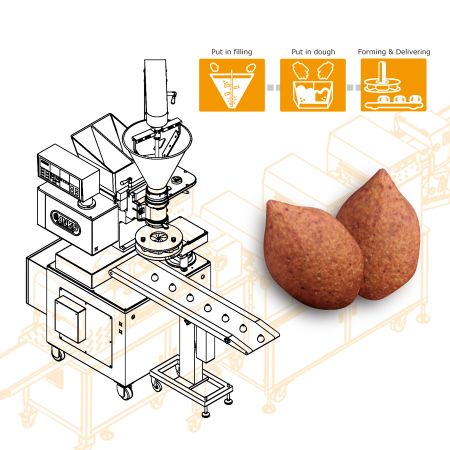

Kibe (Kibbeh) is one of the basic cuisines in the Middle East, so the high demand has made client’s business booming. However, his employees couldn't meet the production requirement and the quality was unstable. To solve the problem, the client has contacted ANKO for food processing equipment solutions.

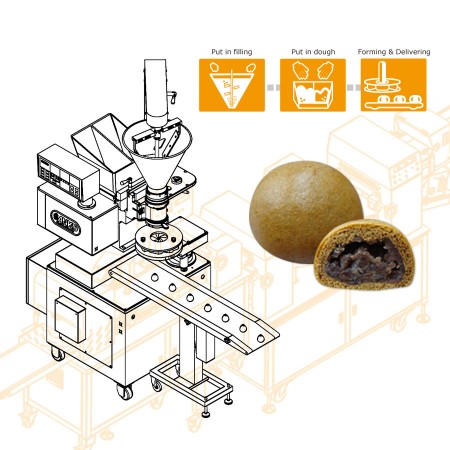

This company owns a bakery, selling various buns and bread. Brown sugar is a common ingredient in Asian cooking, and many people consider it to be healthy food. The client develops a stuffed bun which dough is added brown sugar and which only weighs 12-15g. Since they started selling brown sugar steamed buns, the great popularity has made them hard to handle so many orders. Knowing ANKO is the expert in designing food processing equipment, they contacted us for solutions.

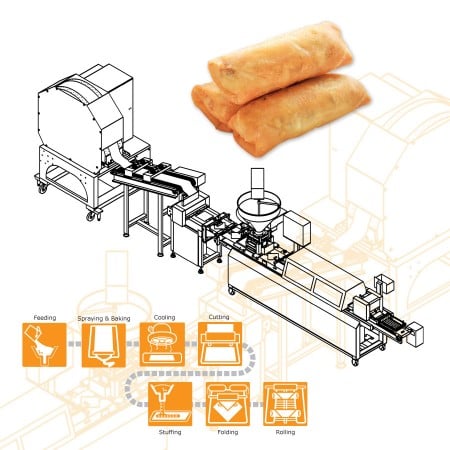

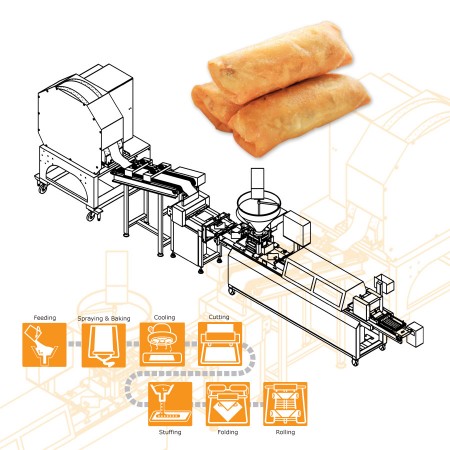

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service. With the gourmet spring roll was getting more popular, insufficient employees could not meet higher demands. At that time, the client was actively seeking a food machine supplier possessing high quality machines and professional services. They heard ANKO produced stable and high productivity spring roll machine. Finally, They decided to rely upon ANKO to increase productivity.

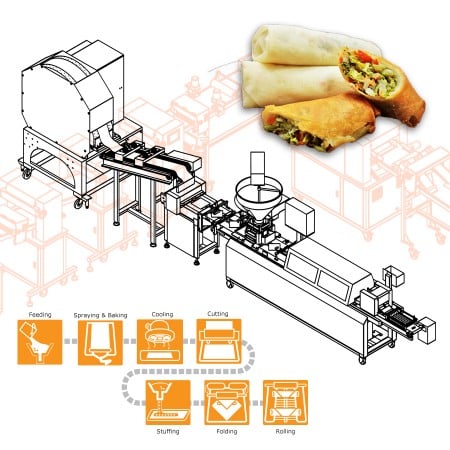

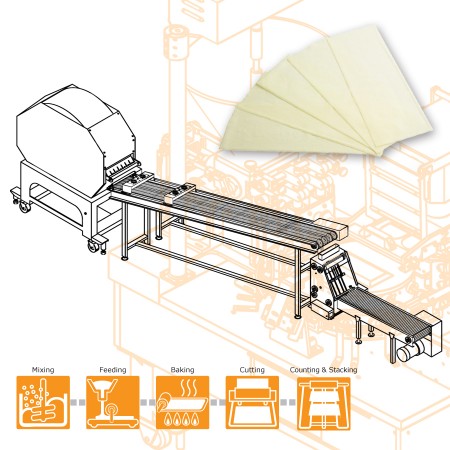

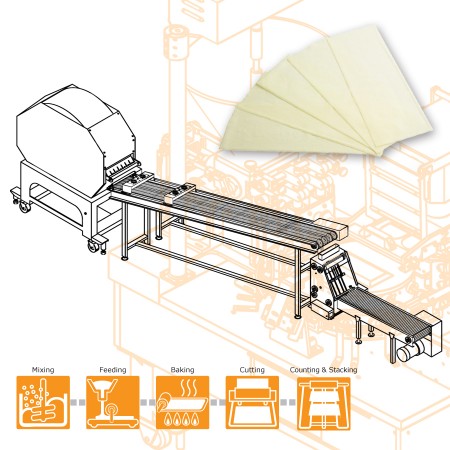

The client has production lines for bakery and ethnic food, including baozi, siomay, hargao, bread, etc. In order to provide the most fresh and best quality food to customers, they have food factories, central kitchens, packaging production line, cooling and frozen facilities. Because their present products stably make profits, they plan to expand the other Chinese dim sum production line to produce spring roll. Hope it can create a new market. Prior to this expansion, the client bought several machines from ANKO for making baozi and satisfied with machine's quality and ANKO's after-sales service, so that ANKO spring roll wrapper machine, which production capacity is high and stable, is exactly what they want. Therefore, it is our pleasure to cooperate with them and satisfy their requirements.

This client operates a bakery business in the Middle East and many other countries in Asia. Their proprietary brand boasts a complete production supply chain, encompassing farms that supply raw materials, factories for processing, baking, and manufacturing, as well as several bakeries, distributors wholesale and retails. As their business expanded, this client actively sought food machinery manufacturers that could provide high quality machines and professional services. They recognized ANKO’s excellent reputation in the industry and acknowledged ANKO's highly efficient and fully automatic Spring Roll wrapper machine. The machine can produce a wide range of products including Samosa wrappers, and Crepes. This diverse product line can reduce production costs significantly, hence, this client chooses ANKO to help them integrate a fully automatic production process to rigorously uphold food hygiene, safety, and quality standards. This collaboration ensured the ability to provide more high-quality and delicious food products to more consumers.

In Canada, the frozen food market is in the keen competition. Locals prefer buying take-out foods or instant foods to save time. The client runs chain restaurants and receives frozen food orders from supermarkets. Because of increasing demands, except for the original machine they bought from ANKO for making wonton, fried dumpling, shumai and the like, they would like to purchase spring roll machinery for expanding their production lines. (The SR-24 is no longer available. The new model is SR-27 machine.)

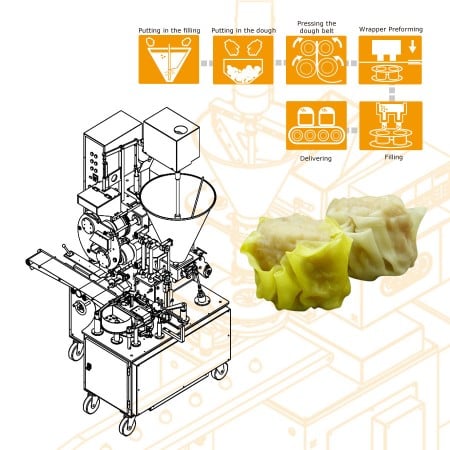

This ANKO client owns an international food corporation, they founded their business providing animal farming and food processing. They own multiple chicken processing food factories in Indonesia, and they have diversified their operations to include food retail business. When their Siomay business started to flourish, the market demand exceeded their production capacity, hence they started to research fully automated and highly efficient Siomay machines for their factory expansion. ANKO is a leading company in the manufacturing of professional automated food machines, and we offered this client production tests to ensure our machines could fulfill their production requirements. This client was very satisfied with ANKO’s machines and production capabilities. In the end, they purchased two HSM-600 Automatic Siomay Machines.

Muslim is the major population in Middle East, which shapes their food culture, halal food. Also, in a fast-paced environment, frozen food becomes one of favorite items in shopping lists. The client is also running business about frozen food like kubba, samosa, chicken fingers. When every producer is keen to develop product differentiation in size or new product, they need a machine supplier who can shortly customize machine to meet individual requirement. ANKO is a professional team; more than half of employees are experienced engineers in which there are over 20 RD engineers. Through interior integration, we quickly react to modify machine as required. Therefore, the client asked ANKO to customize large size filming and pressing machine for him.

The company is well-known in Europe, mainly selling Chinese food. They always take client's health as priority, so they stress that there is no artificial flavors and colorants, no additives, etc. and have the philosophy to strictly and carefully control their products for their consumers. Due to the business expansion, the client wished to increase productivity and find a food machinery supplier with high-quality machine and professional service. In 2006, they heard that ANKO provided high-quality, professional, and stable machinery that the philosophy of machine designing relieved the client. After that, they gave details of their requirement of productivity and local rules of food safety. For ANKO, we considered it's our job to meet their needs and provide comprehensive training and after-sales services so that their consumers can always enjoy safe, hygienic, and delicious food.

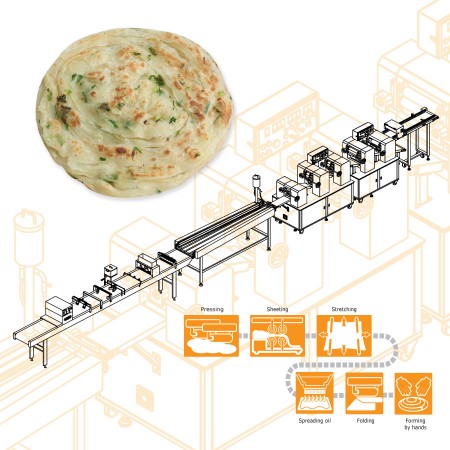

The client is a frozen food wholesaler. He would like to save labor cost and increase productivity. He found ANKO to seek the best solution. ANKO focuses on keeping handmade taste when a client transforms manual production into machine production. For example, the client has produced green scallion pie, which is complicated made by hand. When he tried to produce his products by machine, instead of by hand, one of the difficulties is that the machine cannot repeatedly roll dough into a circle. Therefore, we've made many efforts to eliminate this kind of differences between handmade process and machine-made process. (Note: LAP-2200 is no longer available. The updated model is LAP-5000. Please feel free to contact us for more information.)

An ANKO client operates a baking factory in the Netherlands and exports their baked goods to various European countries, including the UK, France, Germany, and Luxembourg. Recently, this client ventured into the production of Chinese Dim Sum and learned about ANKO through local food industry contacts. Due to our excellent reputation, professional expertise and quality service in the industry, we successfully created an automated Har Gow production line for making high-quality Har Gow that met the client’s expectations.

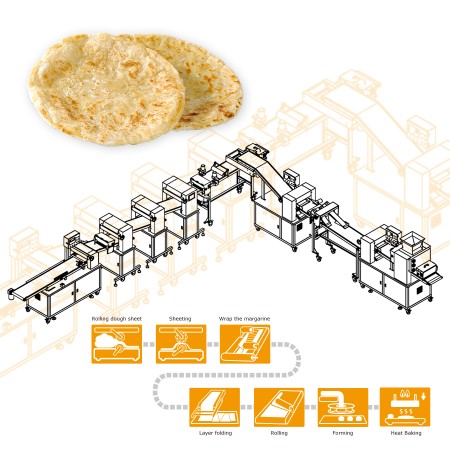

The client had been processing aquatic food products on the beginning of his business and becoming a leader in local food industry. Then, the client established a new plant to produce flour and pastries. Bangladesh is a dense area in which there are tremendous opportunities in the frozen food market. Because paratha is a common food in this area and the client has a flour factory, he decided to run a paratha production line. By word of mouth, they approved ANKO's ability to plan a turnkey. Plus, our advantage is the flexibility of planning production line and installing machine, depending on the client's space. Therefore, they believe in our machines and services, purchasing the whole production line from dough mixer to food packaging from ANKO.

The client's products are Halal food, including spring roll with vegetable stuffing, chicken and onion stuffing, cheese stuffing as well as beef stuffing, permissible for Muslims. At the end of Ramadan, fasting was not required. It was the time for people to go shopping and buy food; as a result, the client received a large number of spring roll (cigar roll) orders. He uses three semi-automatic spring roll production machines, which need employees to wrap rolls by hand. Anko machines are satisfying for him. For the reason, the client considered to order a new spring roll machine with special folding and rolling device, in order to reduce labor costs, increase capacity, and control the quality of standardization. (The SR-24 is no longer available. The new model is SR-27 machine.)

The client already has a spring roll processing machine from other company. Since his business grew, he would like to increase productivity and improve the looks of products. He had been looking for a better solution, also an acceptable price. Finally, ANKO gained favor with the client. It's not only because the machine itself, but our competent team. We have abundant knowledge in food ingredients and recipes; We have years of experience to determine the effect of any conditions, such as temperature, water temperature, pneumatic equipment, or electrical equipment on machinery and food; and last but not least, our engineers are full of passion to find every possible solution. (The SR-24 is no longer available. The new model is SR-27 machine.)

The client produces a wide range of products from dairy products, frozen ready meals to bakery. They are also devoted to customizing innovative foods. Various flavors and delicate appearances are superior to other competitors' products. However, the frozen food market changes all the time. How can the company strictly control costs while guaranteeing capacity and quality? The knack is the combination of machine-made and hand-made processes. They do not just sell unchanged products but garnish foods and vary flavors to surprise consumers. The combined processes not only save time and costs, but also turn the impression of uninteresting products made by machines. It is our pleasure that ANKO's machinery was chosen to shape their basic products, which means that our efficient and high quality machinery gains favor with the client.

The client begins business by manufacturing seasoning. Up to now, the company has been established for more than one hundred years, providing delicious, health, and safety food to gourmets. Since their dim sum products are on the market in 1990, they have applied ANKO's stir fryers (SF Series), dumpling making machines (HLT-700 Series), spring roll production line (SR-24), semi-automatic spring roll production line (SRPF Series) to produce and sale frozen foods, including Chinese fried rice/noodle and various kinds of dim sum, in many countries. With the growth of demands, the supply of Har Gow (Shrimp dumpling), made by hand, was unable to meet a large number of orders. This client still purchased an automatic dumpling machine with Har Gow (Shrimp dumpling) forming device from ANKO because they believe in our machine quality, which achieves the client's ideas with regard to strictly maintaining sanitary environment, controlling every production process, and providing the safest food to consumers.

This ANKO client is a well-known food producer and supplier in India, their frozen food and baked goods are widely distributed throughout the country. Samosa is a popular staple; it can be served as street food snacks, and they are also a key part of festive celebrations. Islam is the second largest religion in India, and Samosas are always in high demand during Ramadan. Therefore, this client was in need of professional commercial food machines that can produce high quality products in large quantities to meet the market demand. The machines they found locally could not meet their product requirements, so they contacted ANKO. Subsequently they visited ANKO’s headquarters in Taiwan. After testing ANKO’s machine with production trials, our professional teams provided many production solutions, and the client was very satisfied with our Samosa Pastry Sheet Machines.

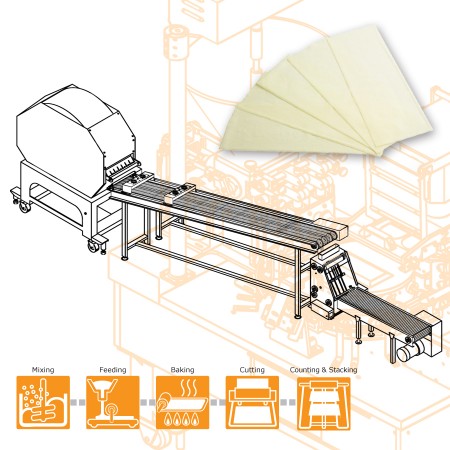

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one, striping pastry. The complex process spends a lot of time and labor costs. ANKO's Samosa Pastry Sheet Machine can hourly produce 16,200 pieces of samosa pastry with standard size and automatically stack in piles. Also, the thickness is adjustable as desired. That results in considerable saving in labor costs. In addition, the machine can produce both spring roll pastry and samosa pastry which helps the client develop a new product line and bring business opportunities. The investment is of great worth, relatively.

The client is a frozen food manufacturer, producing Indian food and selling to grocery stores and supermarkets. The growth of demand for paratha urges the client to seek automatic production line so as to reduce labor cost and increase productivity. The texture and taste of lachha paratha is layered and crispy that ANKO R&D team understands and keeps the characters in machine-made products. Our machine is capable of stretching dough to be pervious to light as well as producing products up to 2,000 pieces in one hour. The client satisfied those advantages of the machine so that they decided to cooperate with ANKO. (Note: LAP-2200 is no longer available. The updated model is LAP-5000. Please feel free to contact us for more information.)

The client runs a bakery group whose divisions are present in many countries of the Middle East and Asia. They form a complete supply chain, including farms for providing raw materials, industrial bakeries for processing food, and numerous retail bakeries and agents. They implement quality control strictly to ensure that products remain their best quality as delivering to consumers anytime. With the business expansion, the client was proactive to find a food machine supplier who delivers not only good quality machine, but also professional after sales services. In 2000, they received information about ANKO's spring roll machine which can produce good quality samosa pastry as well. Such a multipurpose and cost-saving machine was the reason that they decided to cooperate with ANKO. After using ANKO machine for 10 years, due to the stability of the machine, we won their trust. They have ANKO in mind and believe we could help them further expand other new product lines.

Vegetarian foods are the client's primary products. The manual production no longer meets the growing demands. For that reason, automation is what they need to boost capacity and profits.