Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

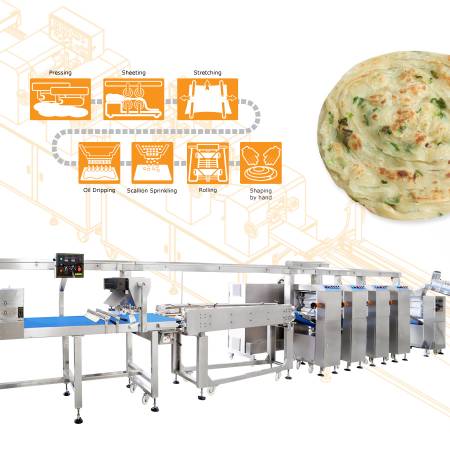

FilipinoTo increase food production capacity and expand food product line are the main reasons that food factory owners contact ANKO. We helped them switch from manual to automatic food production, design food factory layout, optimize food production process, and modify recipe.

With the growth of demand, ANKO's value is to help clients increase efficiency and seize food business opportunity through our food production solutions.

You can find more successful cases that have helpful food solution information you need below or send an inquiry to us now!

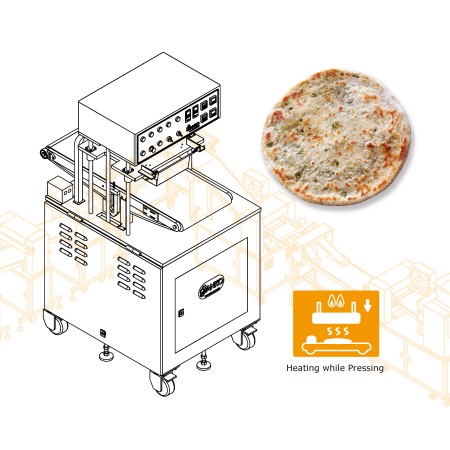

The manual production of Kubba Mosul Pastry relies on a large amount of labor. The ingredients for making pastry and filling must be prepared separately; in addition, shaping a flat circle takes complex steps. Many Middle Eastern immigrants in western countries cannot forget the taste of hometown. Therefore, the market not only in Middle East but also in western countries, there have been marked growing needs for the manufacture of many Kubba Mosul products. A lot of clients hoped to have an automatic Kubba Mosul machine, so that ANKO has kept that in mind and carried out the new project development.

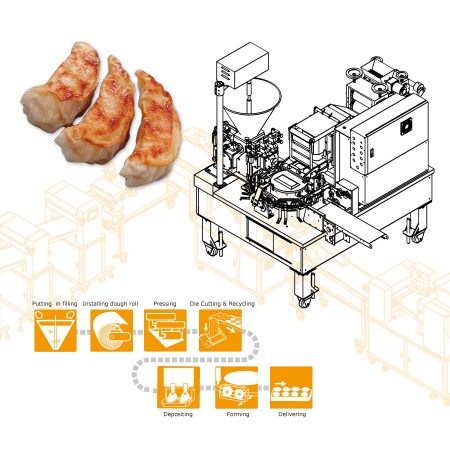

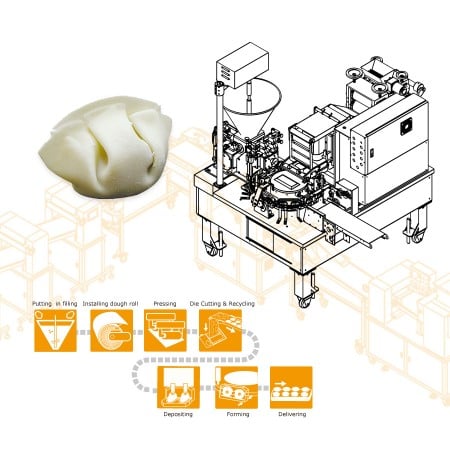

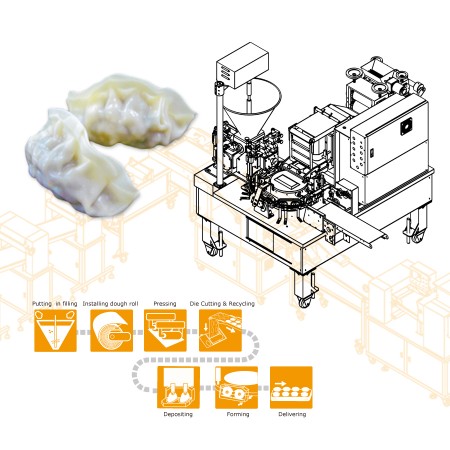

The client, one of our old clients, purchased ANKO's Hargao Forming Machine and Fish Ball Machine. He not only is an OBM of frozen food products but also supply OEM service. In Spanish frozen food market, gyoza was rather new to locals. However, the client was brave expanding an all-new production line on the strength of the well-known brand he created. He hoped gyoza, a dish represents Japanese culture, could be served on the tables in Spain. In order to develop a complete new project, the choice of machine supplier shall be more careful. The client had a pleasant experience of cooperating with us so that he was confident that we were able to plan a whole production line, including machines for preparing ingredients and cooking products such as a steamer, etc. About the gyoza making machine, we recommended him AFD-888, it is with a closing mold device which can produce springier yet firm in taste and more delicate in appearance. The whole project was well prepared and ready to hit the market. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

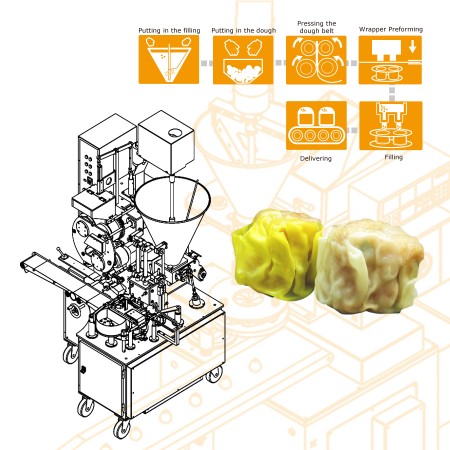

The client runs a vegetarian food processing factory with HACCP as well as Halal certification. Hundreds of vegetarian food products are manufactured by the company and exported to Singapore, Australia, and other countries. With the new online shopping site, they received more orders than before, so that they planned to replace high-cost and low-efficient handmade production with automation. The client has ANKO's Automatic Spring Roll and Samosa Pastry Sheet Machine already that has been smooth without lagging, as a result, they trust in our machine quality. In this case, the client would like to produce two kinds of siew mai with one machine. One is dough wrapper; the other one is tofu skin. Both they and we wondered whether the innovation of tofu skin siew mai could be made by the same machine. The client would like to have a try because we are the only company who offers testing service.

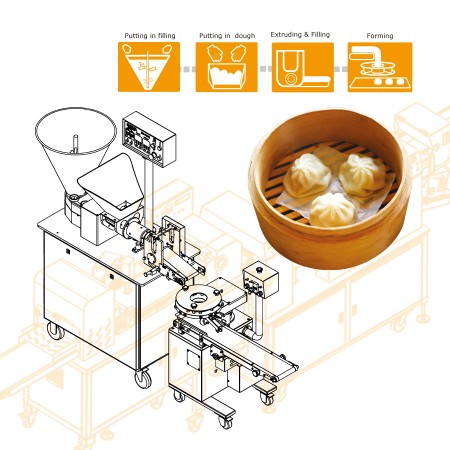

The client operates an air catering company. They offer airline meals to many flights for serving tens of thousands of passengers who travel in and out of China. Shrimp dumpling is an exquisite dish just for business and first class passengers. Due to its complex procedure, rising wages in China, and growing demand, they decided to automate the production of shrimp dumpling. ANKO's Automatic Har Gow Forming Machine manufactures 2,000 pieces per hour and delivers standardized quality control, stable production, simple maintenance and care. They are key factors that contribute to the cooperation.

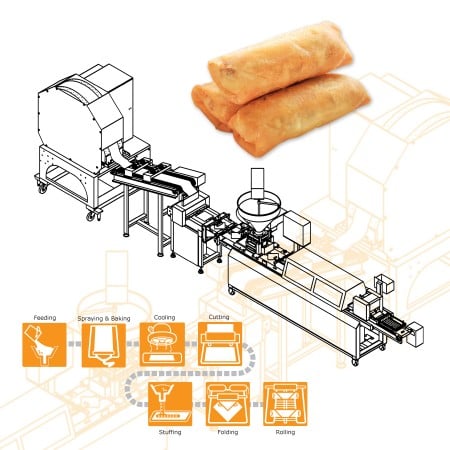

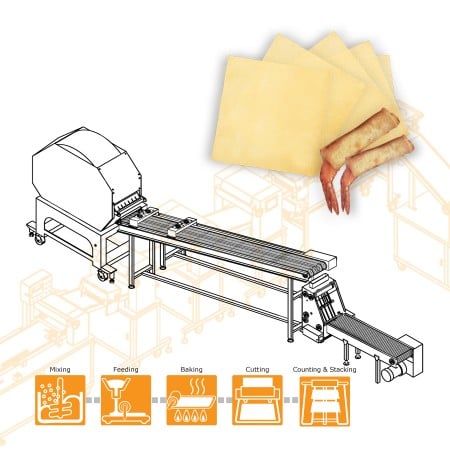

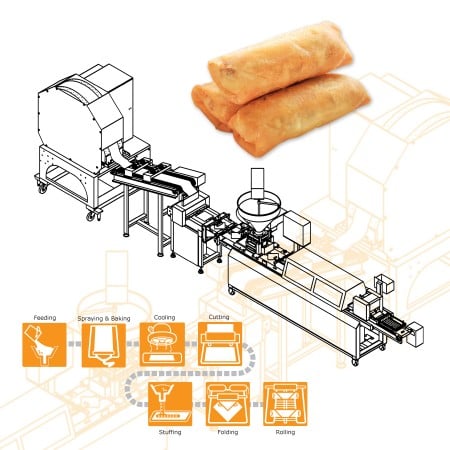

The owner purchased our HLT-series, PP-2, SD-97, SRP, and Automatic Maammoul and Moon Cake Production Line, full of confidence in ANKO's machines. After that, he decided to buy two spring roll production lines (SR-24) at a time, because it produces high-quality and uniform products and can be used in combination with the existing SRP-series to manufacture either pastry or spring roll. It is a massive and wise investment. (The SR-24 is no longer available. The new model is SR-27 machine.)

The client began his business from running a dim sum restaurant, introducing the taste of Chinese cuisine to the Dutch and developing a health-oriented menu. With the growth of business, they established a food processing factory. As looking for equipment, they found that ANKO has years of experience in the field of food equipment and customizing machinery on the basis of individual needs and factory space. Therefore, he decided to cooperate with us. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

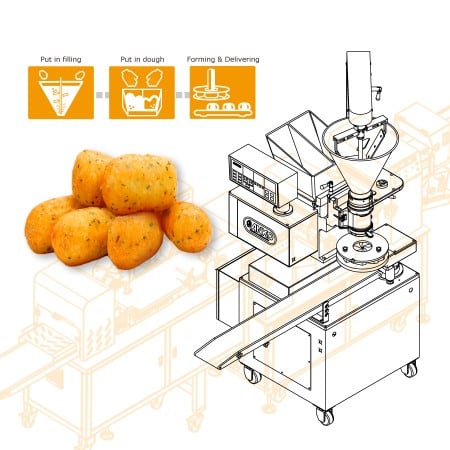

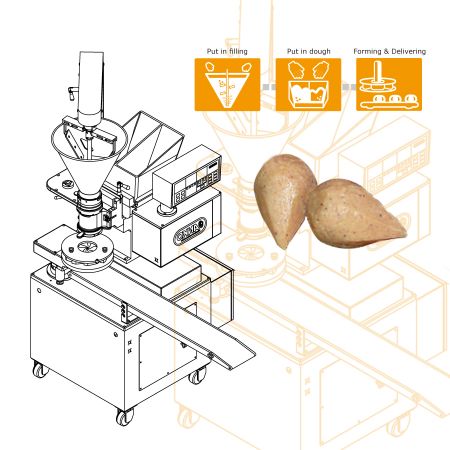

The Peruvian client is the boss of a restaurant and food factory. Our business relationship began with a compact vegetable cutting machine. As he found that ANKO's soft power in research and development as well as abundant recipes, we have become one of his consultants for solutions. The client's stuffed cassava products had been made by hand. When the demand increased to a certain amount, he was seeking a machine that provides labor saving and productivity boosting solutions. In order to ensure product quality, he came to our central kitchen in ANKO headquarters for a machine test run and face-to-face communication with our engineers regardless of the great distance. It's all for the best wrapper/filling ratio and the most appropriate recipe for automatic production.

The company sells processing aquatic food products to all kinds of supermarkets in western countries. They locate their head office in the United States but operate a factory in Sumatra, Indonesia for collecting aquatic resources conveniently. As for spring roll wrapper import, high cost and quality degradation caused by rising temperature during shipping prompted them to purchase a machine to make wrappers by themselves. After searching, they decided to buy ANKO's Automatic Spring Roll Wrapper Machine because our years of experience in spring roll wrapper machine, we are able to adjust ingredients of a recipe according to customer's flour characteristics, and customize our machine to produce different sizes of spring roll wrappers, shrimp spring roll pastries, and samosa pastries, very economic and practical.

The client runs meat processing business which has long history and gains high market share. Now it is the turn that the second generation entrepreneur takes over the company. With current frozen equipment and packaging machinery, they would like to increase efficiency and develop other snacks with product line expansion. ANKO's machinery features multifunction. Take the Automatic Encrusting and Forming Machine as an example, various kinds of dough and filling are suitable for the machine; through parameter adjustment, a wide range of products can be made with one machine. For manufacturers, it definitely a worthy investment to receive a high price/performance ratio.

The client's company had gained a firm foothold in India and then he planned to expand into the U.S. market so that having accurate food quality control and standardization, product line extension, productivity improvement are essential. He compared ANKO with other food machine suppliers and found ANKO is superior to them. ANKO has higher market share in India, offers wrapper and filling recipe to meet individual need, and has years' experience in designing food production routes and supply chain integration. Finally, he chose ANKO as their business partner.

The growing demand for frozen food and take-out food has led to intense competition in the Spanish frozen market. The client has run restaurants and sold frozen food to many supermarkets. Due to the expansion of the market, they needed a complete productivity solution that allowed new dumpling making machine to work well with their packing line and comply with food hygiene regulations. ANKO, as a solution provider, has many related experiences and the ability to customize machines, so they decided to cooperate with us. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy recipes to catch customer's heart. With the increasing popularity of dim sum, he began running a food factory. As seeking food equipment, he knew that ANKO has years of experience in the dim sum making machinery and provides customization in accordance with individual needs and factory planning. Therefore, he decided to cooperate with ANKO.

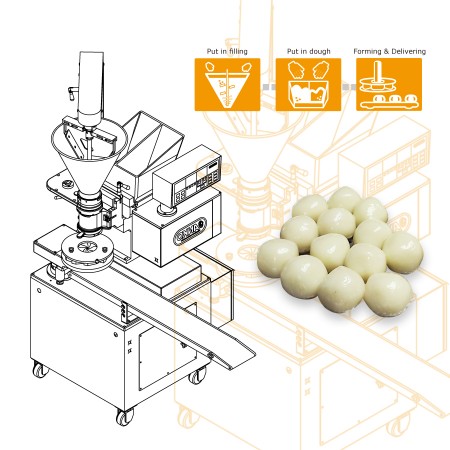

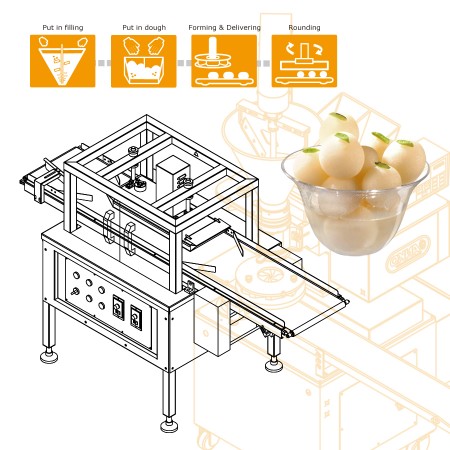

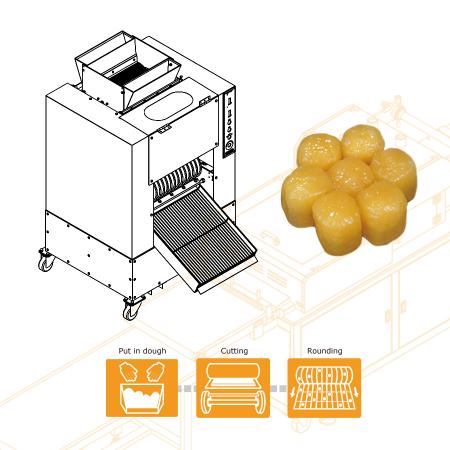

The confectionery factory has established nearly 100 years. They expand their Indian sweets and snacks market along the Indian migration route across the globe. In 2009, in order to increase production capacity and save labor costs, the client contacted ANKO and inquired about the rasgulla automatic production line, which combines SD-97W Automatic Encrusting and Forming Machine with RC-180 Automatic Rounding Machine. In the process of trying out the SD-97W, we adjusted the extruding pressure to maintain the texture of rasgulla. The client was satisfied with the final products and full of confidence in the investment, so he placed an order for three production lines. "Is ANKO trustworthy?" the answer is obvious.

The company is an actively developing food company, offering various sweet potato-based food products, including the popular shaved ice topping-sweet potato balls, and has been dedicated to promoting its brand and products with innovative ideas. A few years ago, they planned to make smaller sweet potato balls that can be added in drink. However, the machinery they had for making average-sized sweet potato balls could not produce such small ones. They found that ANKO has a GD-18B for making tapioca pearls. Afterwards, they visited ANKO for a trial and were satisfied with the machine and our services.

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products online, in supermarkets or deli. Selling products in multi sales channel had leaded to an increasing demand, so the company's owner, via a dealer, had been looking for a supplier who can offer an automated production solution for making kubba. It's always a challenge to make a machine work well with a new recipe. In this case, we had a problem in forming kubba because the crust was too sticky. The just formed kubba would stick to the shutter unit and then be broken while the shutter unit opened. Through recipe and temperature adjustment, ANKO team solved the problem successfully.

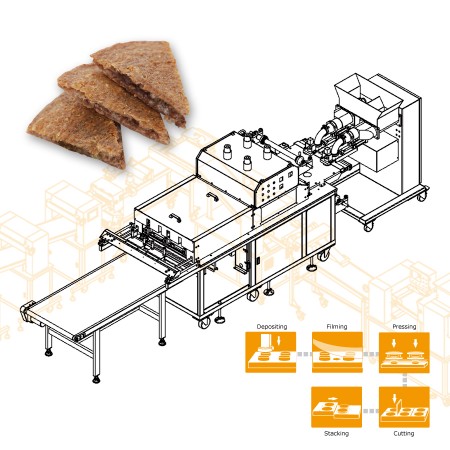

The client inquired a machine for making blini. Our agent gave a test run with ANKO's SRP (Automatic Spring Roll and Samosa Pastry Sheet Machine), but failed to arrange them in a pile. Therefore, ANKO's engineers researched and developed a new stacker to solve the problem.

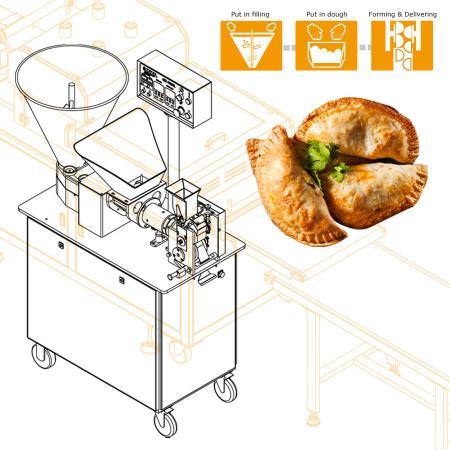

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products online, in supermarkets or deli. Selling products in multi sales channel had leaded to an increasing demand, so the company's owner, via a dealer, had been looking for a supplier who can offer an automated production solution. He was satisfies with ANKO's HLT-700XL model after conducting a test run at ANKO Taiwan headquarters. However, when the machine was commissioned in Egypt, dough was inelastic and couldn't be formed by the machine. The causes might be the characteristics of dough, the weather, or the effect of temperature and humidity. Fortunately, our engineer, who has many years' experience, immediately found the problem and adjusted the dough ingredients. Afterwards, the dough could be processed by the sambousek making machine normally.

In order to increase capacity and improve product quality, the idea of shifting manual to automatic production has been lingering in your mind but you just don't know where to start. Then, you start searching on the Internet. You might find many consulting firms; you might find a lot of food machine companies including ANKO. You might be wondering which kind of company you should call. We have our own factory, so we know making a complete factory plan is important to improve efficiency. Therefore, we offer not only a machine but also consulting services. When your inquiry comes in and our sales clicks on, we assure you can follow us to have a forming machine that suits your needs and front- and rear-end equipment, recipe, machine trial, training and after sales services.

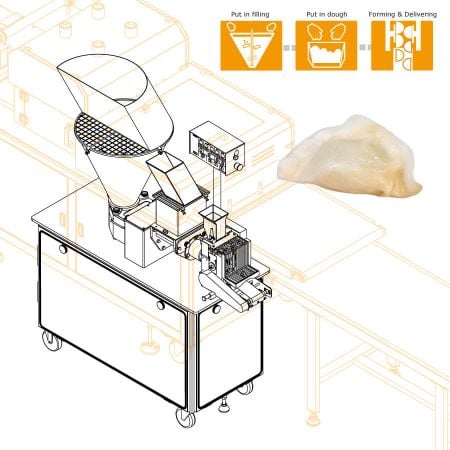

Customers want to increase production capacity by moving from manual to automatic production. However, sometimes machine-made dumplings cannot meet their required shape. Either customers have to give up having handmade pleats and delicate patterns or they stay in manual production. Dumpling machine has been ANKO's bestseller. We have received many inquiries about dumpling shapes. "Do you have other more natural patterns?", "Do you have pinching patterns?", "Do you have other pinching patterns?", "Why is the machine-made dumplings not mouth-watering?" and so on. To response these demands, we started a series of development processes.

The client runs restaurants, Indian food retail stores, and food factories at the largest Indian community in Birmingham, UK. Their major consumers are the Indians in the UK. Years ago, the client bought a food machine from ANKO. Without a machine trial before purchase, its user-friendly design, intuitive operation, and stable production and ANKO's services gave him a great impression. Therefore, he placed another order for spring roll production line this time because he thinks ANKO is reliable. (The SR-24 is no longer available. The new model is SR-27 machine.)

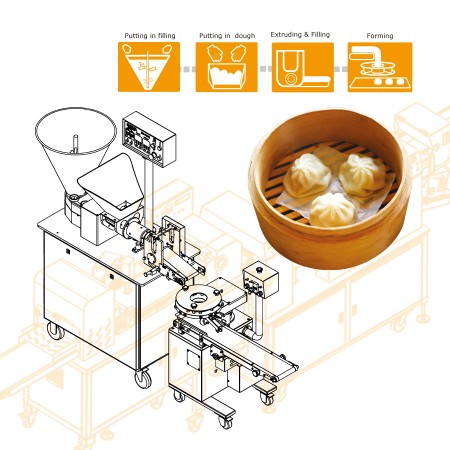

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply and problems with staff management had come out. It took an average of three months for a new employee to become fully productive. Therefore, the client started finding an automatic solution. At first, the client knew ANKO by searching from the Internet and visiting IBA Munich, which is a trade show held in Germany every two years, but he didn't contact us until the next IBA Munich. He placed an order without having a machine trial because he thought ANKO had considerable experience in food machinery. He purchased an HLT-700XL Multipurpose Filling and Forming Machine and an EA-100KA Forming Machine. With these two machines, he could make a wide variety of dishes, such as dumpling, steamed dumpling, crystal dumpling, fun guo, soup dumpling, increase production capacity and decrease labor costs. Moreover, when ANKO's engineer conducted on-side commissioning, our engineer helped solve his problem that soup dumplings had no soup.