Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

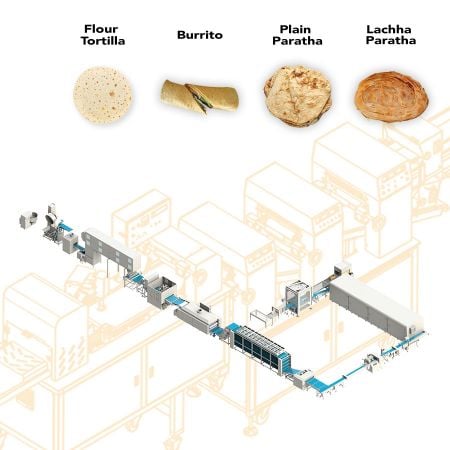

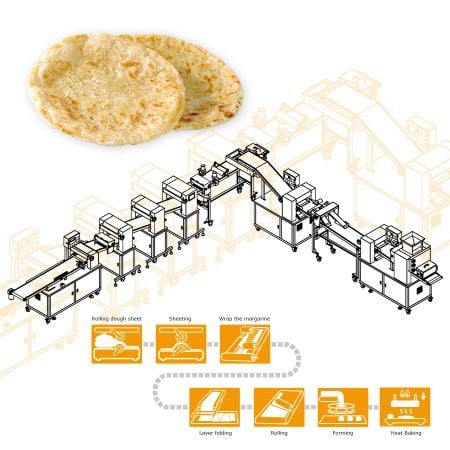

ANKO has newly configured four Integrated Production Lines to meet the manufacturing needs of Flour Tortillas, Burritos, Plain Parathas, and Lachha Parathas. More than 1.5 billion people worldwide consume these products, representing a major global market. Globally, medium-sized food manufacturers make up the majority of the industry. However, when faced with surging order volumes, labor shortages, and mounting competitive pressure, these businesses often need to transition toward scaled and automated production. Flatbread production is more complex than other foods, requiring consistent quality and efficient output. ANKO’s solution integrates dough feeding, forming, packaging, inspection, carton sealing, and environmental monitoring into one streamlined system—helping clients upgrade their production with ease.

This UK-based Indian food manufacturer, specializing in Punjabi Samosas, relied on manual labor to produce 1,000–1,500 pieces daily. With growing competition in the UK's Indian food market, scaling production and boosting revenue became increasingly urgent. After an in-depth consultation, ANKO found no existing machine could mass-produce the pyramid shape of traditional Punjabi Samosas. To help the client gain a competitive edge, ANKO spent over a year developing the world's first PS-900 Punjabi Samosa Forming Machine. Throughout development, the client visited ANKO's Taipei headquarters for filling tests and function validations. This breakthrough enabled automated production, reduced labor costs, and created a differentiated product, strengthening their market position and accelerating brand growth.

This client has been operating a food factory in South Africa for over 30 years, specializing in high-quality frozen foods, including samosas, rollups, and waffles. With strong brand recognition in the local market, the client first visited ANKO’s booth at the IBA exhibition for an initial consultation. At that time, they had no immediate need for automation and did not pursue further contact. A year later, as their existing product sales stabilized, they decided to develop a new product. After conducting market research, they discovered that Meat Pies are highly popular in the region. This led them to reconnect with ANKO to explore automation solutions. With our professional assistance, we customized unique patterns for their Chicken Pies, successfully differentiating their products in the market and enhancing their brand identity.

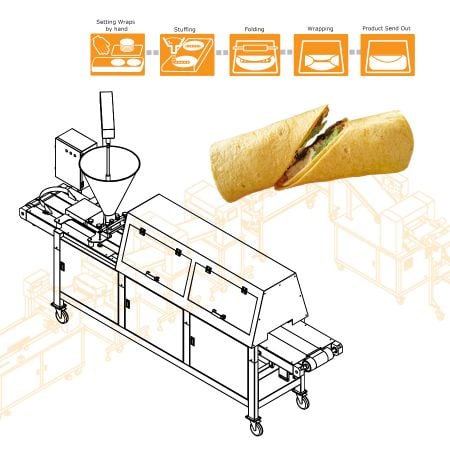

An ANKO client runs a well-known Indian food company in the United States. The company has many brick and mortar stores across the U.S., and their products are also sold in supermarkets and through wholesale channels. This client was purchasing pre-made tortillas and handmaking Burritos, but rising labor costs in the U.S. necessitated a change to automated production. They learned about ANKO through their peers, and scheduled product test runs with ANKO Food Tech. After several trials and adjustments, our team assisted the client to be able to produce Burritos made with Chicken Tikka and Vegetable Curry fillings.

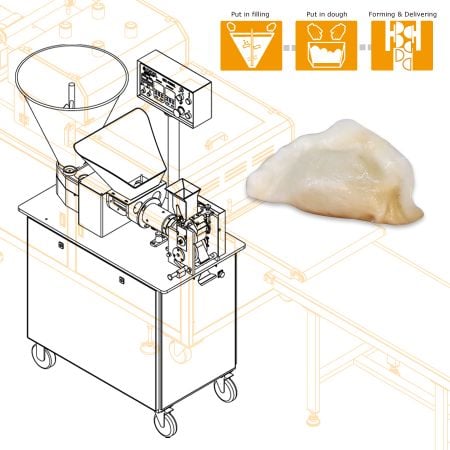

This client is a third-generation Chinese American who inherited his grandfather's wholesale food business in the United States. A few years ago, his company had to adjust to accommodate the changes in the overall marketplace and focused on producing and distributing Chinese cuisines. After thorough market research, the client purchased ANKO's HLT-700U Multipurpose Filling and Forming Machine to make authentic Chinese Dumplings. After nearly a year of market testing, which showed promising sales, the client further invested in the ER-24 Automatic Egg Roll Production Line and AF-589 Conveyor Fryer a year later. ANKO's high-quality and durable food machinery has successfully helped clients excel in authentic Chinese food production and become leaders in the market.

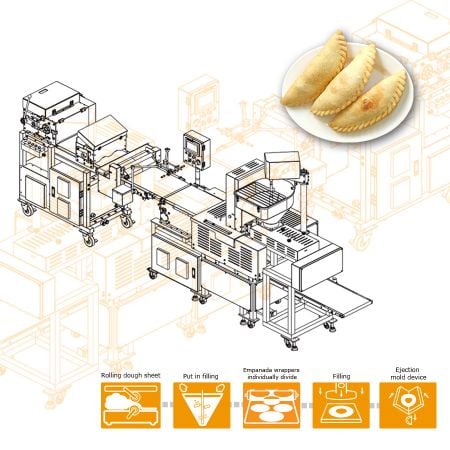

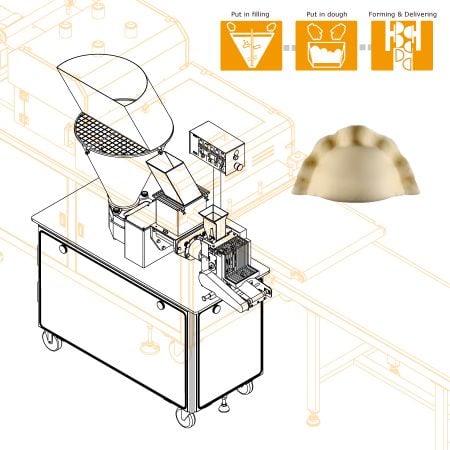

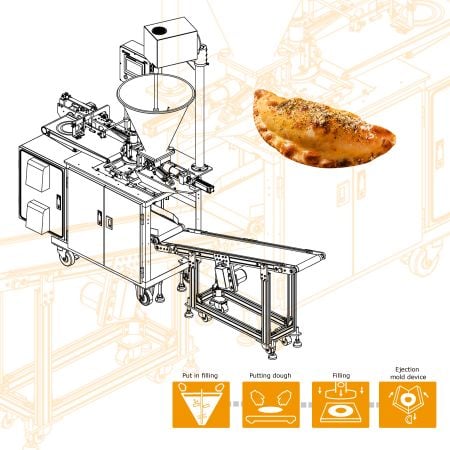

ANKO developed the high-capacity EMP-3000 Empanada Making Machine based on a client’s requirements in the United States. Our team conducted an in-depth analysis of operations at the client’s facility to understand the challenges of their Empanada production. This client needed a machine that could “quickly adapt to market demands while maintaining a high-quality product output.” After multiple test runs and refinement, the ANKO EMP-3000 Empanada Making Machine was launched. This model has a capacity of producing 3,000 Empanadas per hour to help clients’ productivity while saving on labor costs. The easy-to-remove filling system enables continuous production and improves quality control, providing a competitive advantage in food manufacturing.

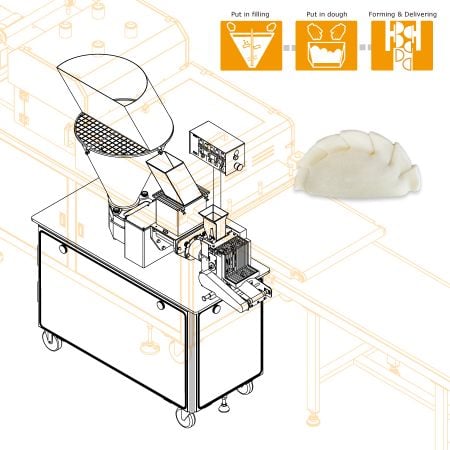

Production automation is inevitable in the food manufacturing industry, and ANKO aims to "assist manufacturers in achieving high production automation goals." In 2024, we launched the "Xiao Long Bao Integrated Production Line" as an integration concept to connect various related production parts. Within a year, ANKO successfully launched the world's first Xiao Long Bao Production Line, supported by our "automated food production solutions" system to further increase food production efficiency and reduce overall labor requirements. ANKO ensures that smart technology is applied to your food production process to increase product quality, consistency, and taste to provide competitive advantages.

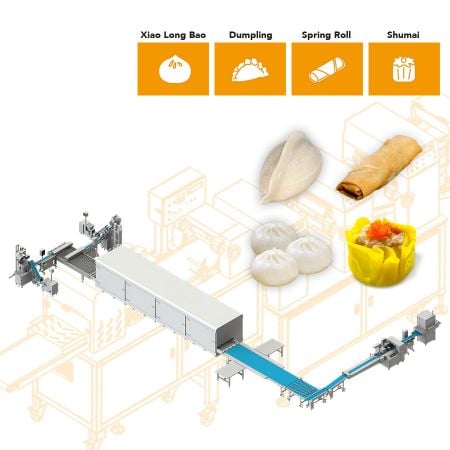

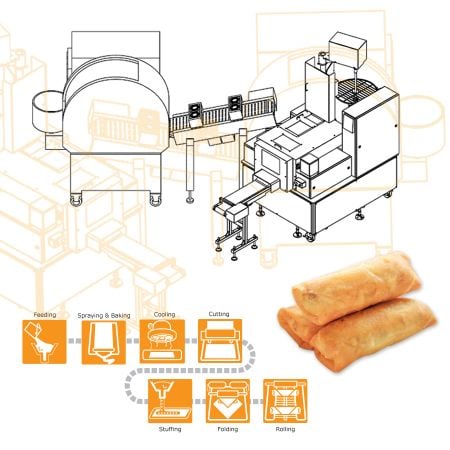

The global food market is rapidly changing. When peak seasons arrive, urgent orders always come quickly. When facing global labor shortages and ever-changing consumer tastes, food companies are eager to find more flexible and efficient production models to respond to market demand. ANKO's newly launched "Integrated Production Line" is designed to resolve the difficulties associated with food manufacturing. Our newly designed production lines include Dumplings, Shumai, Spring Rolls and Xiao Long Bao, providing everything from feeding systems, forming machines, to packaging and various inspection equipment. ANKO's streamlined labor configuration has a daily output of 150,000 pieces! We can also provide solutions for other food products, configuring appropriate production equipment to optimize efficiency and implement a smooth integrated transition.

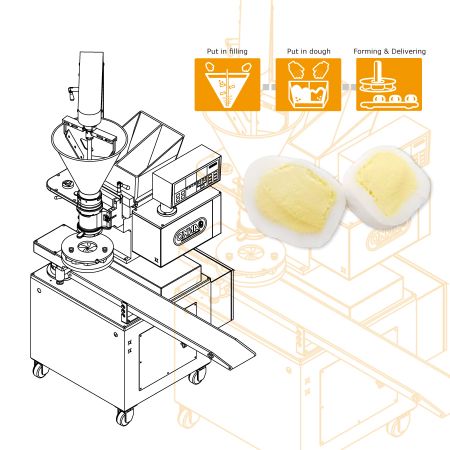

An ANKO client operates a restaurant in Los Angeles serving authentic Asian specialty foods, and Mochi is one of their best-selling desserts. Many diners enjoy ending their meals with an order of Mochi, often paired with tea or coffee. Our client wanted to increase their revenue by making their popular Mochi available for takeout, but they didn’t have enough labor to accomplish this plan. While searching for automated food machine options, this client discovered ANKO Food Tech and scheduled a machine trial. ANKO recommended using the SD-97W Automatic Encrusting and Forming machine to the client for making Mochi and Mochi Ice Cream. The client was very impressed with the machine demonstration, and the taste of the final products. Based on their volume, they decided to purchase the SD-97SS Table-Type model. After delivering the machine, our team helped the client to familiarize themselves with the production process, machine maintenance routines, and overall operations.

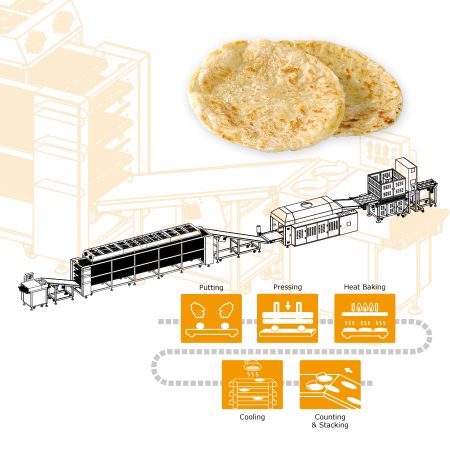

This ANKO client is a well-known food manufacturer in Bangladesh, and their business scope includes multiple food fields. They have been using semi-automatic equipment to produce Paratha to supply their domestic market demand. To expand their Paratha sales internationally, this client purchased ANKO’s fully automated food machines to produce an estimated 100,000 pieces per day in order to meet the global market demand. This ANKO return customer is confident in our high-quality machine performance and the professional support services we provide. Our team customized a Triple Line High Capacity Paratha Production Line for this company. With the assistance of ANKO’s Bangladeshi local distributors, this client visited our Taiwan headquarters to conduct trial machine operations, and the results successfully met the client’s required production requirements and food specifications.

An ANKO client operates restaurants and takeout shops in Australia; they also own a food factory and sell their products in supermarkets. Their food items include Har Gow (Shrimp dumplings), Tang Baos, Dumplings, and Buns. Recently, many food businesses have started using automated production equipment due to labor shortages in Australia. This client is a great example. They purchased ANKO’s HLT-700XL Multipurpose Filling And Forming Machine, EA-100KA Forming Machine, SD-97SS Automatic Encrusting And Forming Machine, and other ANKO machines to produce a wide range of products. They successfully transitioned to automated food production, increased productivity, and resolved labor issues. ANKO’s engineers helped the client maintain the machines and develop new Har Gow flavors successfully.

Mexican food is popular in the U.S and a favorite cuisine around the World. ANKO has developed many innovative food machines to supply to Mexican food manufacturers, such as our TT-3600 Tortilla Production Line, and the BR-1500 Burrito Forming Machine. After market research and testing, ANKO recently launched our QS-2000 Quesadilla Making Machine. This is the world’s first automated machine that produces high quality Quesadillas with great consistency and efficiency rate and minimal required labor. This machine solves production problems including labor shortages, and insufficient productivity, and also allows producers to better allocate their production resources.

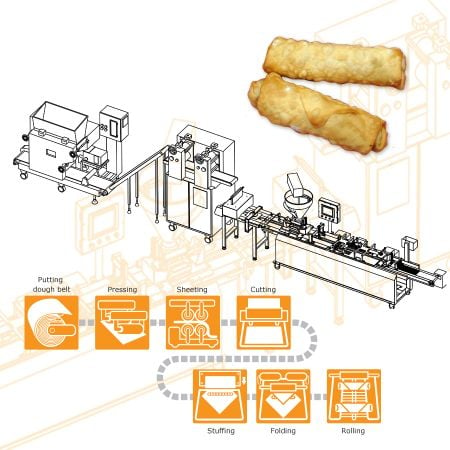

This customer's factory is in California which has the largest population of Chinese people in the United States. They specialize in the manufacturing and wholesaling of Chinese food including Dumplings, Har Gow, Baozi, Spring Rolls, Shumai, etc. They have a distribution center in their local area, and consumers can buy their products in supermarkets, direct wholesale, and from other distributors. This customer owns ANKO’s HLT-700XL Multifunctional Filling and Forming machine, SD-97W Automatic Dumpling Machine, HSM-600 Automatic Shumai Machine, and the SRP Automatic Spring Roll Pastry sheet machine. As the demand for spring rolls has continued to increase, the customer learned about ANKO's latest SR-27 Spring Roll Machine and they immediately contacted us to arrange a demonstration. In addition to the vegetable and pork Spring Rolls the customer originally produced, they requested to test run using cheese and apple cinnamon fillings because of their desire to develop innovative new Spring Roll products and capitalize on the growing Sweet Spring Roll market.

![ANKO Smart Machine – Pioneering The Integration of Internet of Things [IoT] in Automated Food Production](https://cdn.ready-market.com.tw/aa42f2c9/Templates/pic/m/HLT-700U-Dumpling.jpg?v=db51b6c8)

ANKO regards the IoT system as the foundation for new automated production lines when transforming into an intelligent factory influenced by the Industry 4.0 movement. Our new IoT system was officially introduced in December 2022 after more than three years of development working with system integration companies and various feasibility tests. ANKO introduces our IoT system to the HLT-700U Multipurpose Filling and Forming Machine, to satisfy the increasing market demand for various Dumplings and similar food products that our clients request Worldwide. During the development stage, a Taiwanese client used ANKO’s HLT-700U to produce Dumplings and based on their feedback, our engineers continued to improve our IoT system. After multiple user testing and verification, this client was very satisfied with the advantages ANKO’s IoT system provided to their production needs. ANKO is able to assist businesses transition into smart manufacturing, and we are also proud to have achieved new milestones in smart machine innovation and in the food production process.

An ANKO client operates a food factory in Poland that specializes in manufacturing frozen foods. Pierogi is one of the national staples of Poland. This client initially relied heavily on producing Pierogi manually, then later switched to automated production using machines from a different manufacturer and encountered unresolved production issues. Then they discovered ANKO’s HLT-700U Multipurpose Filling and Forming Machine, which is perfect for producing Pierogis, and it was supplied by ANKO’s local agent in Poland; it has a CE Marking and comes with Artisanal forming molds that can create dumplings that closely resemble traditional handmade Pierogis. Our client was satisfied with ANKO’s machine, production solutions, and our local agent was also very supportive with providing our client with current market insights.

An ANKO client is from the Philippines had a Spring Roll factory before moving to the USA. After relocating to the USA, this client started another production operation with semi-automatic Spring Roll machines and began to sell their products. With increasing sales and market demand, this client approached ANKO for assistance with building a production line that could meet their increased production requirements. After rigorous communication, ANKO’s R&D team developed the SR-27 Automatic Spring Roll Production Line which has a capacity of producing 2,400 to 2,700 pieces per hour, and a newly designed filling system that can process a wide variety of ingredients. Toward the final stages of this project, ANKO offered remote product testing and virtual meetings to ensure the client was satisfied with the results. This client was very pleased with ANKO’s automated food machine, customized consultation services, and the increased production volume.

An ANKO Client has been producing a variety of high-quality Roti (Indian style flatbread) and has established a distribution system in wholesale, retail, and supermarkets. During the COVID-19 pandemic, the local food market in the Netherlands experienced a dramatic increase in demand for frozen Roti, as more people were cooking at home. While the company’s production capacity was not able to meet the new demand, they reached out to ANKO and requested assistance to help them transition into automated production. Due to the pandemic and travel restrictions, this client mailed their ingredients to Taiwan and ANKO started production trials and communicated with this client remotely. ANKO’s engineers customized a production solution utilizing ANKO’s SD-97W Automatic Encrusting and Forming machine and APB Pressing and Heating machine for automated Roti production. This production line is compact and highly efficient which exceeded the client’s expectations.

An ANKO client based in Los Angeles has 35 years of commercial food sales experience in supplying Shanghainese Spring Rolls, Meats, Baos, canned goods, sauces and seasonings to wholesalers and restaurants. Recently, they saw the increasing demand for Egg Rolls, therefore they decided on establishing an automated Egg Roll production line. ANKO’s ER-24 Automatic Egg Roll Machine was the perfect machine for this client, and after a few product test runs and recipe adjustments, ANKO successfully assisted this client in creating a new food production line, and in doing so, create a new business opportunity for them.

ANKO has found there is an increasing demand for Empanadas in the World marketplace. ANKO’s research has determined that this phenomenon not only exists in Spain and Latin American countries, but also in the USA, Canada, Australia, and the Philippines. And as a result, there is a great demand for automated Empanada machines. ANKO has been approached by many companies and different clients seeking a machine that can process high fat content dough such as puff pastry in order to make Empanadas. Currently, ANKO’s HLT-700 Multipurpose Filling and Forming Machine can produce Spanish style Empanadas with the capacity of over a thousand pieces of products per hour using a variety of forming molds. ANKO’s new EMP-900 Empanada Making Machine is our latest design for making Empanadas with high fat content pastry dough. ANKO’s team has devoted much time researching and developing our Semi-automated Clamping Mold Device, and it was tested using ANKO’s client’s recipe from the USA. This machine has successfully produced Empanadas that can be either baked or deep-fried and fulfilled ANKO’s client product specifications.

This client is a pioneer in introducing Chinese Dim Sum for European markets; they started producing and selling premade frozen Dim Sum products to many different wholesale and retail stores in Europe and accomplished great brand recognition. However, considering the high labor costs in most European countries, this client approached ANKO for an automated production assessment. In order for their business to improve and expand they decided to purchase ANKO’s HSM-600 Siumai Machine; soon after this purchase the client returned to ANKO and purchased ANKO’s HLT-700XL Multipurpose Filling and Forming Machine for producing Har Gow (Shrimp dumplings). The purchase of both ANKO machines helped them accomplish their production requirements and meet market demands.

In Taiwan, most traditional noodle machines have good productivity but are limited in the types of noodles the machines can produce. Hence, ANKO’s team worked with Taiwan’s Food Industry Research and Development Institute to test and co-create an innovative noodle extruding machine. One client who owns a noodle factory approached ANKO for equipment that can produce unique noodles, and this company was the first to test ANKO’s NDL-100 Noodle Extruder. The client found ANKO’s machine to be highly productive with the ability to produce many different types of noodles which met their production needs and thus they purchased the machine.

A client and her partners started a business in Singapore. These entrepreneurs later decided to invest in the Chinese Dim Sum business in 2019. Initially they purchased equipment from a supplier in China, but the equipment was not as user friendly and required multiple employees to operate. Additionally, they encountered many difficulties and problems during their manufacturing processes. Fortunately, this very same client found ANKO. ANKO is a company that is dedicated to Quality and Productivity while offering customized production solutions for various food products and catering to each of our client’s unique requirements. This client purchased ANKO’s HLT-700XL and EA-100KA for producing dumplings and Xiaolong soup dumplings. The company supplies many schools with dumplings, and they are also working with many central kitchens. With ANKO’s equipment this client was able to establish their own brand since have enjoyed great success.

An ANKO client is a major food manufacturer in Kenya and had a business expansion plan to increase market share and revenue in the local food business in Kenya. That was why they wanted to invest in creating a new product - East African Chapati (Paratha). The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO’s products and services were the best. When they initialed the order, ANKO worked diligently to provide customized production line and all the necessary support needed for a successful implementation!

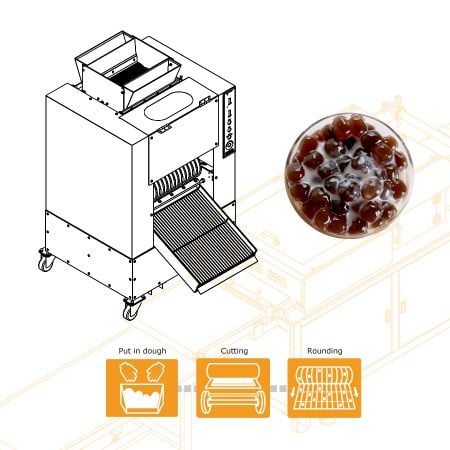

This Taiwanese client had started their business in canned food production for export, mainly sold to North America, Australia and New Zealand, but recently discovered the increasing tapioca pearl demand worldwide, and the client has many existing customers who are owners of shave ice and tea/beverage shops. This Taiwanese client had no experience in tapioca pearl production and originally wanted to find an OEM but was referred by the OEM company to consult with ANKO. After ANKO’s team had successfully developed the tapioca pearl products the client had desired to produce, they purchased ANKO’s GD-18B Automatic Cutting and Rounding Machine which is currently in production.