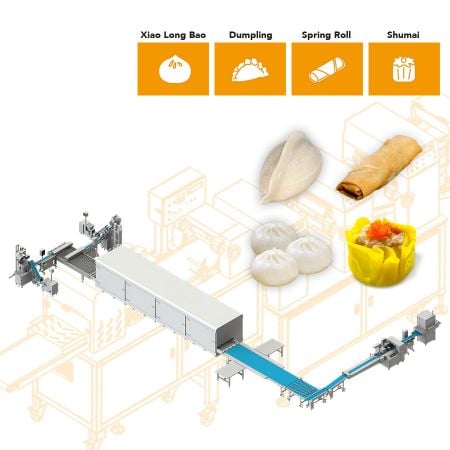

ANKO's new "Integrated Production Lines": Has a Daily Production Capacity of 150,000 pcs, streamlining labor resources!

The global food market is rapidly changing. When peak seasons arrive, urgent orders always come quickly. When facing global labor shortages and ever-changing consumer tastes, food companies are eager to find more flexible and efficient production models to respond to market demand. ANKO's newly launched "Integrated Production Line" is designed to resolve the difficulties associated with food manufacturing. Our newly designed production lines include Dumplings, Shumai, Spring Rolls and Xiao Long Bao, providing everything from feeding systems, forming machines, to packaging and various inspection equipment. ANKO's streamlined labor configuration has a daily output of 150,000 pieces! We can also provide solutions for other food products, configuring appropriate production equipment to optimize efficiency and implement a smooth integrated transition.

Dumpling / Shumai / Spring Roll / Xiao Long Bao

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. How to configure an integrated production line?

ANKO's "Integrated Production Lines" are configured for your specifications and can be adjusted to meet different production requirements and changing labor allocations. We initiate the design process by gathering crucial information as follows:

1) Production Components

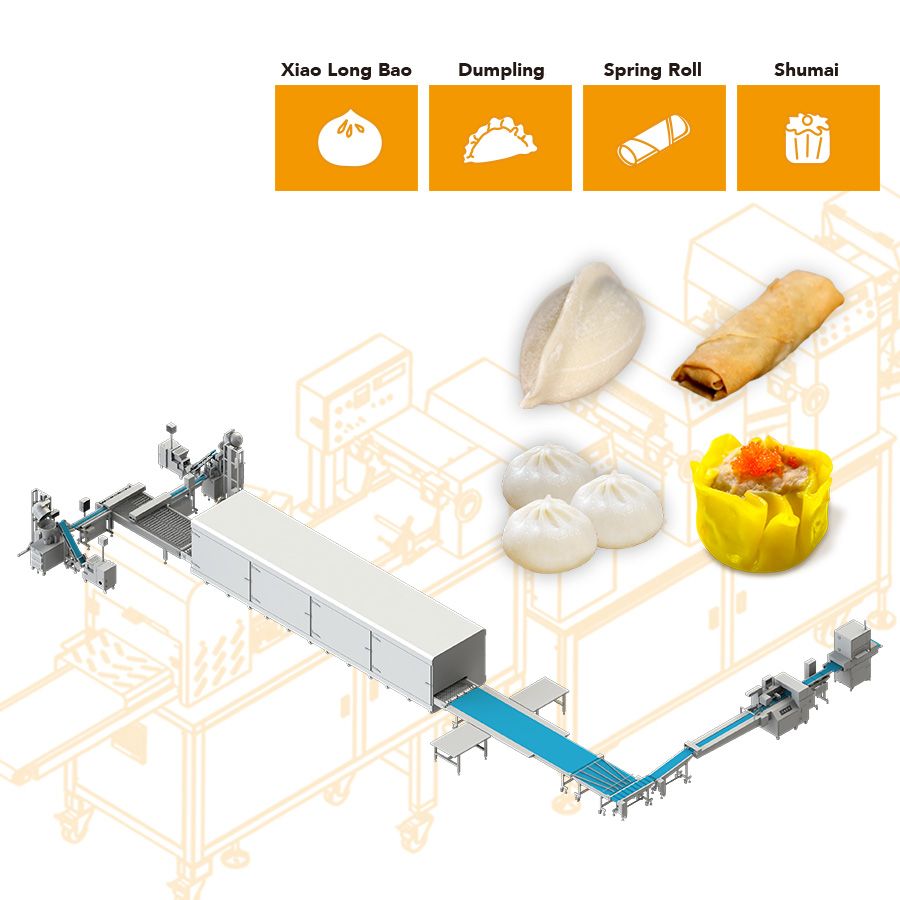

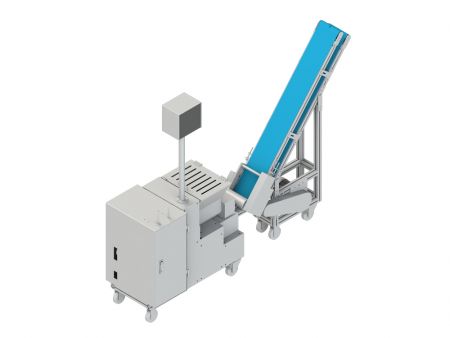

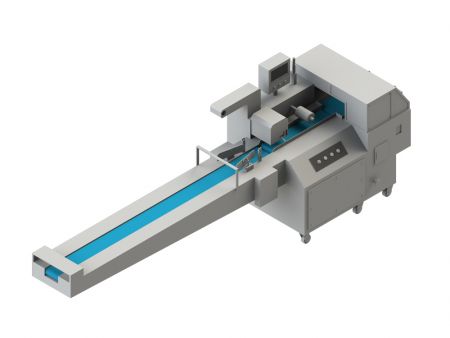

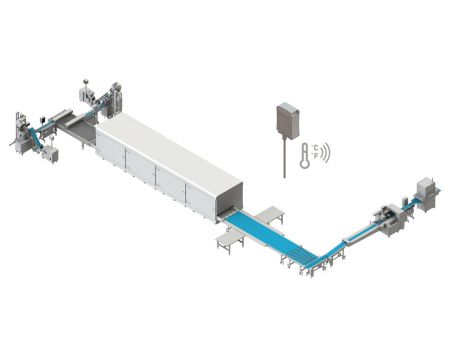

ANKO offers more than ten functional components, ranging from dough and filling feeding systems, forming machines, and cooking equipments to freezing, packaging, and X-Ray inspection equipment. Our engineers are adept at understanding your existing production configuration and future requirements, allowing us to arrange compatible components such as robotic arms, conveyor belts, and assisted manual production setups that perfectly align with your needs.

2) Available Space

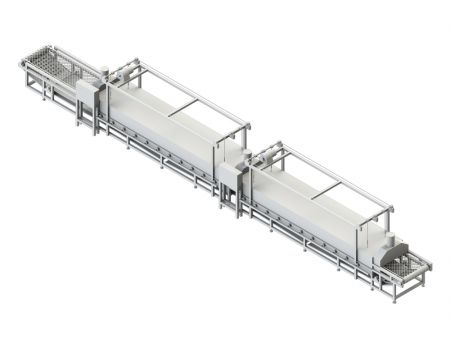

Our engineers obtain the space available in the factory to design the best-suited integrated production. In doing so, we determine the most appropriate layout, between straight, U-shaped, or other customized designs, to fit your space and curate a smooth workflow. ANKO has the experience and uses our advanced technology to create the perfect production design for your requirements.

3) Production Capacity

Integrated production lines are designed according to the required production capacity. For example, production configurations requiring a daily production capacity of 150,000 pieces and 300,000 pieces are entirely different. ANKO will plan dual-line or even triple-line configurations for companies with high production capacity needs to achieve ultra-high performance output and facilitate proper food distribution capabilities.

Solution 2. What are the benefits and advantages of Integrated Production lines?

Food manufacturers are transitioning to automated production lines due to global labor shortages and are also seeking professional consultants to help them with this transition. Therefore, ANKO has introduced our Integrated Production Lines with increased automation and capacity to give you competitive business advantages.

1) Increased Production Efficiency

ANKO’s Integrated Production Line seamlessly connects each of the production components to boost overall production efficiency substantially. Take our Integrated Dumpling Production Line, for example. It revolutionizes the process, transforming a task requiring significant labor to input filling, dough, and complete packaging into a streamlined operation that demands minimal labor. The result is a considerable increase in productivity, a substantial decrease in labor costs, and a remarkable reduction in human errors.

2) Reduce Overall Labor Costs

The components in the production line are integrated with various automated equipment to reduce overall labor requirements. The simplified production process utilizes more efficient manual labor, requiring less employee training time and costs. This can also be the solution to high turnover rates and workplace hazards.

3) Quality Control

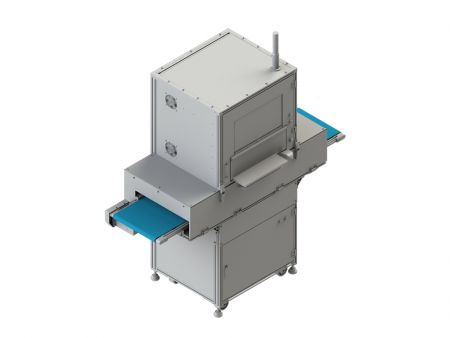

The quality of manufactured products made with individual machines is more likely to be affected by the workplace environment. Our Integrated Production Lines are highly automated, and each part of the production process can be monitored so issues can be easily recognized and addressed. ANKO also includes an X-ray inspection machine to detect any foreign objects in the final products to ensure ultimate quality.

4) Increased Production Competency

Standardized operational procedures in Integrated Production Lines can quickly maximize production capacity within a short period to fulfill unexpectedly large orders. For example, ANKO’s Integrated Dumpling Production Line, when producing 25g Dumplings, has a daily capacity of 150,000 pieces. This is especially advantageous when creating and launching new products to meet new trends and various consumer demands in a competitive market.

5) Reduced Production Costs

Our Integrated Production Lines are designed with parameter settings that can be finely tuned to adjust the wrapper/filling ratio, thereby determining the final product weight and minimizing production waste. The automation of each component into one seamless production line ensures maximum efficiency. For instance, once Dumplings are formed, they are automatically transported to the tunnel freezer, packaged, and then undergo weight inspection and X-Ray screening. This fully automated process eliminates the need for additional storage or manual processing, leading to significant reductions in production costs and increased profit margins.

Solution 3. Is ANKO’s Integrated Production Line compatible with food machines made by other manufacturers?

ANKO’s Integrated Production Line is designed to integrate with food machines from different manufacturers, creating one efficient production line. We understand that every piece of equipment is a significant investment. Therefore, our professional consultants assess a client’s existing machinery and production specifications prior to providing the best design solution to integrate all components into one seamless production line.

Capacity Breakthrough – ANKO’s Integrated Production Line

ANKO has configured four Integrated Production Lines designed for producing Dumplings, Shumai, Spring Rolls, and Xiao Long Bao. Based on experience and expertise, we configured feeding systems, packaging devices, and inspection machines to achieve maximum capacity. Our professional consultants can also offer recipe consultation to improve your product’s appearance, taste, and texture. Contact ANKO about our integrated production lines and inquire how we can be your valued technical equipment supplier.

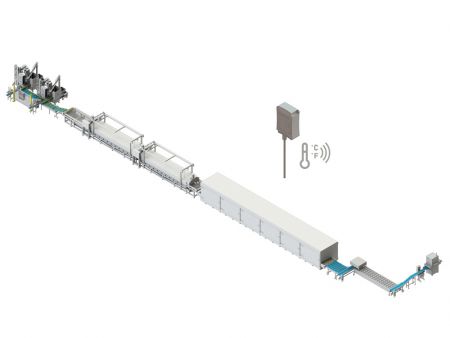

Integrated Dumpling Production Line (SOL-DPL-T-1)

Product Name: Dumpling / Product Weight: 25g / Capacity: 400 – 500kg/hr / Labor Requirement: 7-8 ppl / Min. Space Required: 23,000(L) x 14,000(W) x 2,500 (H) mm

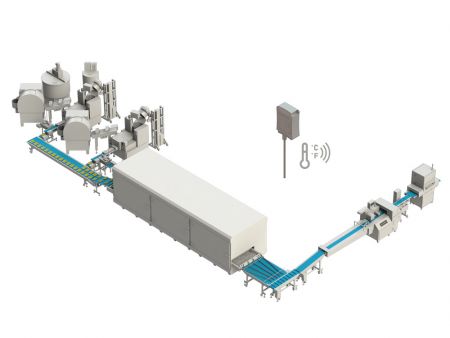

Integrated Shumai Production Line (SOL-SHM-T-1)

Product Name: Shumai / Product Weight: 23g / Capacity: 350-410kg/hr / Labor Requirement: 3-4 ppl / Min. Space Required: 48,000(L) x 10,000(W) x 2,700 (H) mm

Integrated Spring Roll Production Line (SOL-SPR-T-1)

Product Name: Spring Roll / Product Weight: 45g / Capacity: 200-240kg/hr / Labor Requirement: 3-4 ppl / Min. Space Required: 20,000(L) x 11,000(W) x 2,300 (H) mm

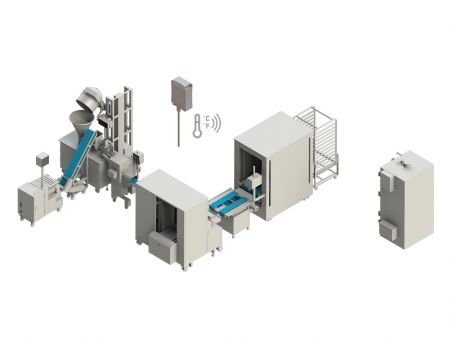

Integrated Xiao Long Bao Production Line (SOL-XLB-T-1)

Product Name: Xiao Long Bao / Product Weight: 30g / Capacity: 180kg/hr / Labor Requirement: 2-3 ppl / Min. Space Required: 7,300(L) x 6,300(W) x 2,300(H) mm

Note: The configurations and components of the above Integrated Production Lines are for reference only. The actual designs will be customized to meet your actual production requirements.

- Solution Proposal

Professional Experience and Customization: Keys to Success

ANKO has successfully assisted clients in the United States with building Spring Roll Production Lines. Additionally, we have helped clients in Spain configure automated Gyoza production equipment and Dumpling Production Lines for clients in Italy. We have custom-designed and built a triple-line automatic Paratha Production Line with a daily output capacity of over 100,000 pieces. Over the past 47 years, ANKO’s professional machinery and customized services have successfully supported numerous worldwide manufacturers. More and more food businesses are contacting us for our expertise in automated production solutions. ANKO’s Integrated Production Lines are designed for clients who desire automation and increased efficiency in their food production. If you are interested in ANKO’s Integrated Production Lines, please complete the inquiry below, and we will get back to you as soon as possible.

- Video

ANKO’s Xiao Long Bao Integrated Production line includes feeding systems for filling and dough, forming machines, automatic aligning and rack loading machines, and cooking equipment. It requires only 2 to 3 employees to produce up to 6,000 pieces of Xiao Long Bao per hour. ANKO also offers fast freezing equipment, packaging devices, and inspection machines to fulfill different production requirements. All components are integrated to provide production efficiency and adaptability.

- Category

English

English