Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

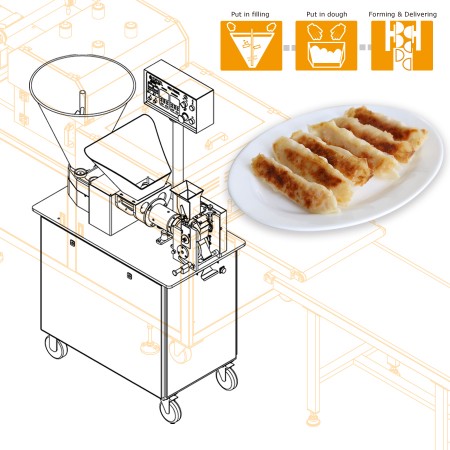

The long-established North China cuisine restaurant is owned by a veteran emigrating from China. Its signature dish --potsticker--is many people's all time favorite, as a result, the supply was often unable to meet the demand. Then, they decided to manufacture potstickers with machine and took the opportunity to improve the appearance of their potstickers. In the end, they found ANKO because we offer customization services and project solutions. The project was totally different from the development of other standard potsticker making machines. During the period of research and development, we'd tried potstickers with both-end-open, both-end-close, different sizes and types of sealed ends as well as given them many professional suggestions patiently. Finally, the customized forming mold for making both-end-close potstickers and the final products satisfied their needs and gave them more confidence in boosting sales in the future.

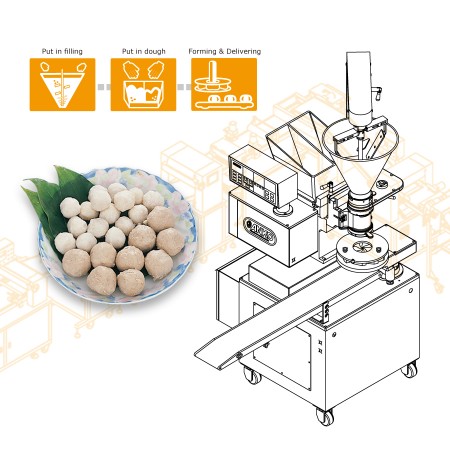

The client has two fishing vessels and two fish processing plants to process the six-ton daily catch. One plant is dedicated to mince fish into fish paste, and the other plant is for the production of fish balls and fish products. He purchased a HLT-700XL Multipurpose Filling & Forming Machine and a SD-97W Automatic Encrusting and Forming Machine from ANKO. The HLT-700XL is used for producing deep-fried fish snacks — a new offering made of springy fish paste with a crispy wrapper. And the SD-97W is for making stuffed fish balls. The client's new plant covers 10,000 square meters and employs around 50 people. Their products are mainly sold to local supermarkets in Indonesia such as Carrefour.

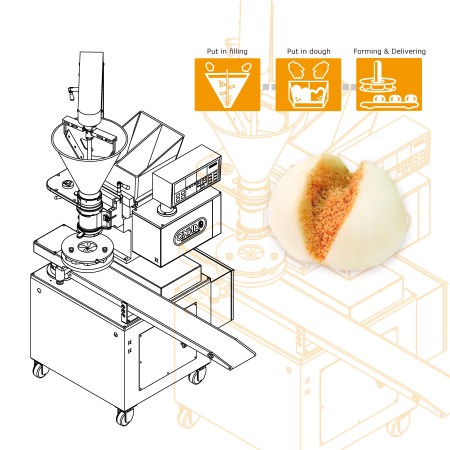

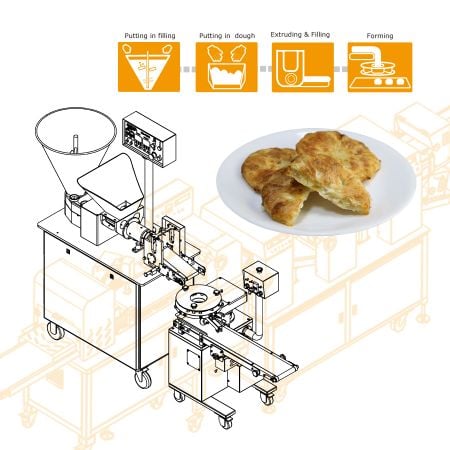

The client runs meat processing business which has long history and gains high market share. Now it is the turn that the second generation entrepreneur takes over the company. With current frozen equipment and packaging machinery, they would like to increase efficiency and develop other snacks with product line expansion. ANKO's machinery features multifunction. Take the Automatic Encrusting and Forming Machine as an example, various kinds of dough and filling are suitable for the machine; through parameter adjustment, a wide range of products can be made with one machine. For manufacturers, it definitely a worthy investment to receive a high price/performance ratio.

The client's company had gained a firm foothold in India and then he planned to expand into the U.S. market so that having accurate food quality control and standardization, product line extension, productivity improvement are essential. He compared ANKO with other food machine suppliers and found ANKO is superior to them. ANKO has higher market share in India, offers wrapper and filling recipe to meet individual need, and has years' experience in designing food production routes and supply chain integration. Finally, he chose ANKO as their business partner.

The client sells a great variety of foods. Although glutinous rice ball was not one of the main products, he needed a solution to produce glutinous rice balls effectively. Therefore, he visited ANKO's booth at a Hong Kong exhibition. Compared to other glutinous rice balls, the client's filling recipe contains more ingredients, including peanut powder, coconut powder, and sugar powder, which makes workers hard to fill the same ingredient quantities into each glutinous rice ball. Nevertheless, it is also difficult for machine to extrude powder filling because it easily tends to clump up and clog the filling system. Therefore, for making stuffed food with powder filling, ANKO's Automatic Encrusting and Forming Machine with a special designed powder filling system is highly recommended.

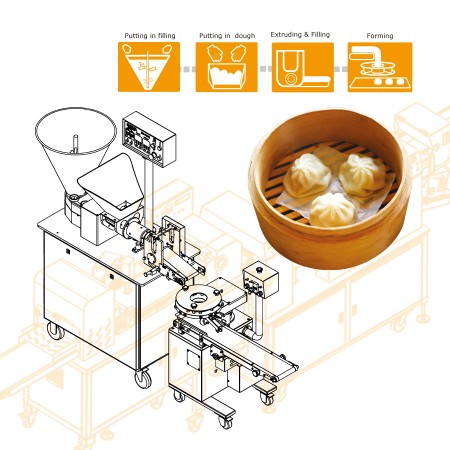

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy recipes to catch customer's heart. With the increasing popularity of dim sum, he began running a food factory. As seeking food equipment, he knew that ANKO has years of experience in the dim sum making machinery and provides customization in accordance with individual needs and factory planning. Therefore, he decided to cooperate with ANKO.

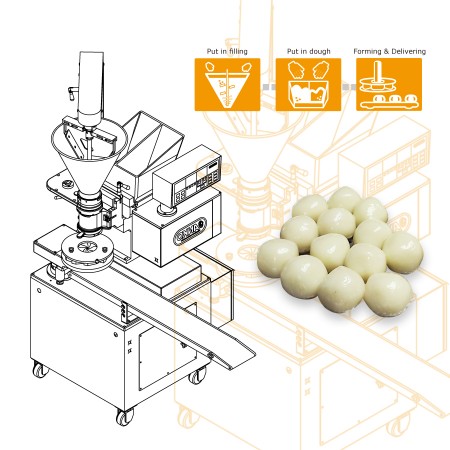

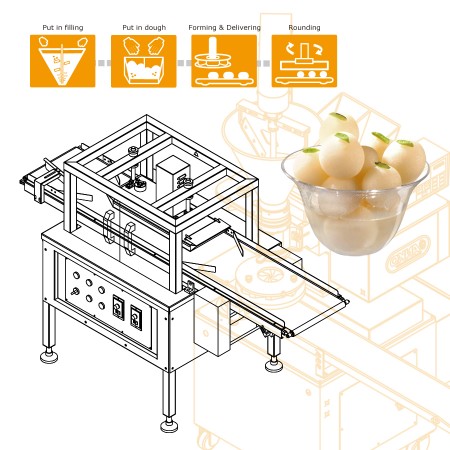

The confectionery factory has established nearly 100 years. They expand their Indian sweets and snacks market along the Indian migration route across the globe. In 2009, in order to increase production capacity and save labor costs, the client contacted ANKO and inquired about the rasgulla automatic production line, which combines SD-97W Automatic Encrusting and Forming Machine with RC-180 Automatic Rounding Machine. In the process of trying out the SD-97W, we adjusted the extruding pressure to maintain the texture of rasgulla. The client was satisfied with the final products and full of confidence in the investment, so he placed an order for three production lines. "Is ANKO trustworthy?" the answer is obvious.

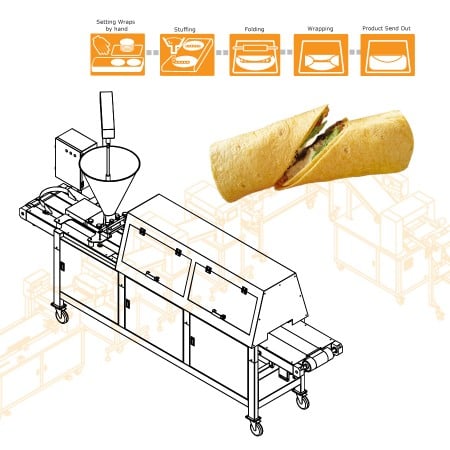

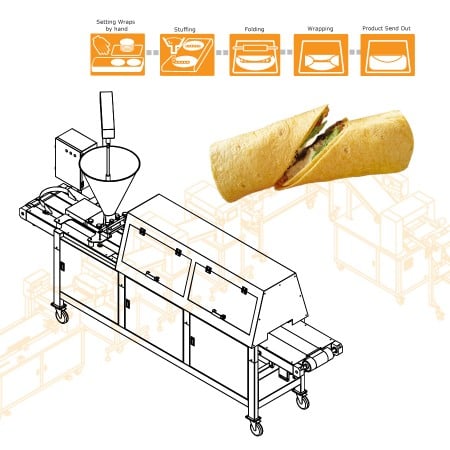

The client has run the company offering Mexican food for over 25 years. They not only have privately-held restaurant chains, but also distribute more than 20 flavors of frozen burritos to supermarkets. However, when their burritos were getting popular, the production capacity of their current production lines could not meet the increasing demand. Then, they found that ANKO has developed burrito forming machine, so they came to Taiwan looking for a solution to increase productivity.

ANKO’s client is a manufacturer of Mexican food products and has distribution in several countries in Latin America and Southern Europe. Burritos are one of the items that this client produces, and this client has decided to transition from manual production to an automated assembly line due to the increasing product demand and labor costs. This client was introduced to ANKO FOOD TECH (AFT) through a referral; and subsequently this client visited AFT for a demonstration, and they were very satisfied with ANKO’s machines, and the products made by our automated system. Additionally, with ANKO’s guidance this company was able to restructure their business, to save on manufacturing costs and focus on their sales and marketing performance for market expansion.

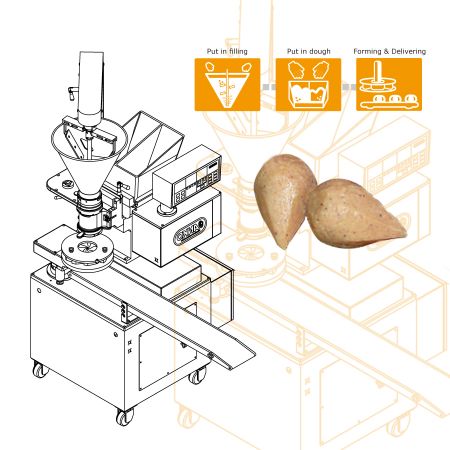

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products online, in supermarkets or deli. Selling products in multi sales channel had leaded to an increasing demand, so the company's owner, via a dealer, had been looking for a supplier who can offer an automated production solution for making kubba. It's always a challenge to make a machine work well with a new recipe. In this case, we had a problem in forming kubba because the crust was too sticky. The just formed kubba would stick to the shutter unit and then be broken while the shutter unit opened. Through recipe and temperature adjustment, ANKO team solved the problem successfully.

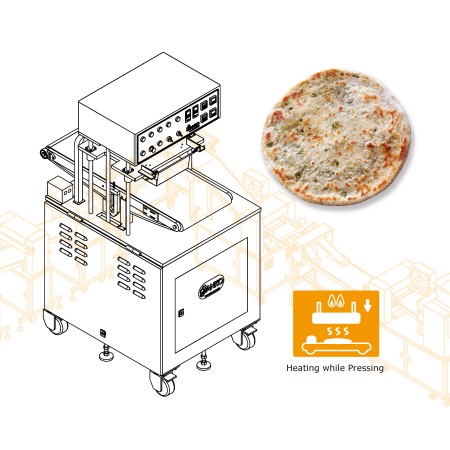

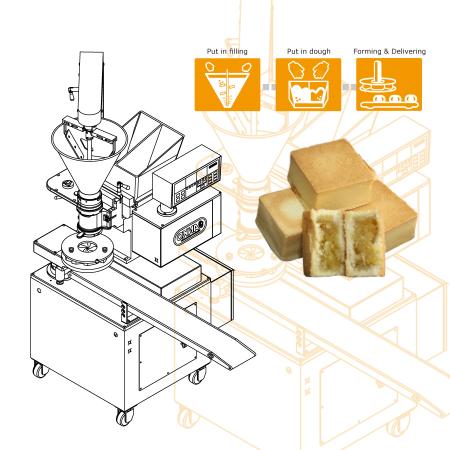

It is a food and beverage company, producing frozen and fresh food, and owning over 30 casual dining restaurants. Most materials of the company's products are from its own farms. With the concept of providing organic food and additive-free products to consumers, the owner insists on growing plants with organic farming. The owner found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell them in his retail stores. However, he had no experience in making pineapple cakes. After having a discussion, we proposed a pineapple cake tailor-made total solution to him, including pineapple cake recipe, equipment, and training. Finally, he entrusted ANKO with the new product line.

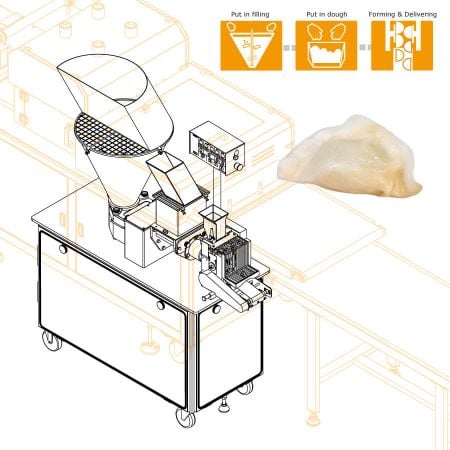

To increase capacity and standardize products are the main issues that drive food manufacturers and restaurant owners, including this client, to switch from manual to automatic production. The dumplings served in the company's restaurant chains were made by hand in its own central kitchen. Consumers really liked the handmade dumplings, but 'sold out" was the most important issue with which the company had to deal. Moreover, the size, weight, and taste of handmade dumplings might vary from batch to batch. Using a dumpling maker can both improve capacity and achieve standardization. Therefore, he chose us as the solution provider for the automatic production of dumplings. He also wanted to serve deep-fried dumplings and steamed dumplings to satisfy customers' appetite after increasing capacity.

In order to increase capacity and improve product quality, the idea of shifting manual to automatic production has been lingering in your mind but you just don't know where to start. Then, you start searching on the Internet. You might find many consulting firms; you might find a lot of food machine companies including ANKO. You might be wondering which kind of company you should call. We have our own factory, so we know making a complete factory plan is important to improve efficiency. Therefore, we offer not only a machine but also consulting services. When your inquiry comes in and our sales clicks on, we assure you can follow us to have a forming machine that suits your needs and front- and rear-end equipment, recipe, machine trial, training and after sales services.

Customers want to increase production capacity by moving from manual to automatic production. However, sometimes machine-made dumplings cannot meet their required shape. Either customers have to give up having handmade pleats and delicate patterns or they stay in manual production. Dumpling machine has been ANKO's bestseller. We have received many inquiries about dumpling shapes. "Do you have other more natural patterns?", "Do you have pinching patterns?", "Do you have other pinching patterns?", "Why is the machine-made dumplings not mouth-watering?" and so on. To response these demands, we started a series of development processes.

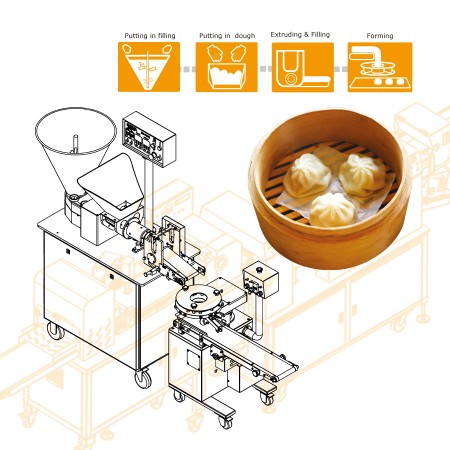

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply and problems with staff management had come out. It took an average of three months for a new employee to become fully productive. Therefore, the client started finding an automatic solution. At first, the client knew ANKO by searching from the Internet and visiting IBA Munich, which is a trade show held in Germany every two years, but he didn't contact us until the next IBA Munich. He placed an order without having a machine trial because he thought ANKO had considerable experience in food machinery. He purchased an HLT-700XL Multipurpose Filling and Forming Machine and an EA-100KA Forming Machine. With these two machines, he could make a wide variety of dishes, such as dumpling, steamed dumpling, crystal dumpling, fun guo, soup dumpling, increase production capacity and decrease labor costs. Moreover, when ANKO's engineer conducted on-side commissioning, our engineer helped solve his problem that soup dumplings had no soup.

The owner's kompia is so delicious that people are willing to travel a long way to his store in a rural area. However, 1,000-1,200 kompias made by five people a day were not able to meet the demand. That made people feel disappointed and sometimes brought customers into conflict. The client contacted ANKO's Malaysian distributor for SD-97SS, but after a machine trial, ANKO's engineer thought that the HLT-700XL and EA-100KA was more suitable for kompia dough that was firmer for making crispy kompia, while the SD-97SS is suitable for soft fermented dough for creating fluffy texture. Therefore, our engineer immediately decided to use HLT-700XL and EA-100KA to make some samples. With the samples and ANKO's soft power of food and ingredients, the client had complete confidence in us and placed an order.