Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

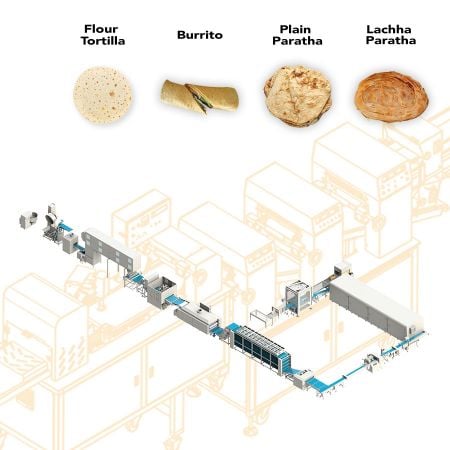

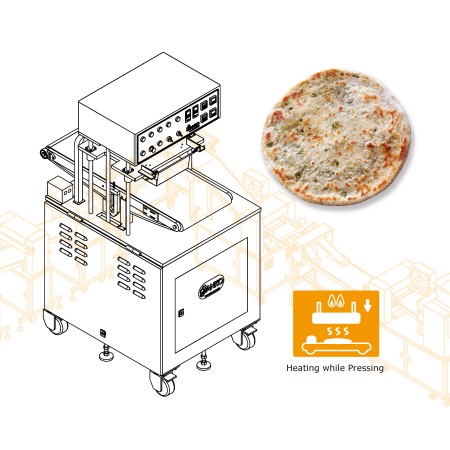

ANKO has newly configured four Integrated Production Lines to meet the manufacturing needs of Flour Tortillas, Burritos, Plain Parathas, and Lachha Parathas. More than 1.5 billion people worldwide consume these products, representing a major global market. Globally, medium-sized food manufacturers make up the majority of the industry. However, when faced with surging order volumes, labor shortages, and mounting competitive pressure, these businesses often need to transition toward scaled and automated production. Flatbread production is more complex than other foods, requiring consistent quality and efficient output. ANKO’s solution integrates dough feeding, forming, packaging, inspection, carton sealing, and environmental monitoring into one streamlined system—helping clients upgrade their production with ease.

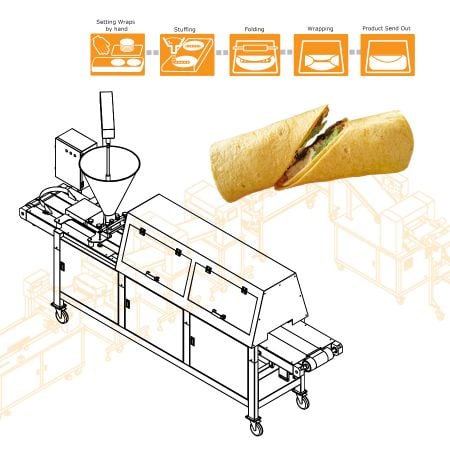

An ANKO client runs a well-known Indian food company in the United States. The company has many brick and mortar stores across the U.S., and their products are also sold in supermarkets and through wholesale channels. This client was purchasing pre-made tortillas and handmaking Burritos, but rising labor costs in the U.S. necessitated a change to automated production. They learned about ANKO through their peers, and scheduled product test runs with ANKO Food Tech. After several trials and adjustments, our team assisted the client to be able to produce Burritos made with Chicken Tikka and Vegetable Curry fillings.

Mexican food is popular in the U.S and a favorite cuisine around the World. ANKO has developed many innovative food machines to supply to Mexican food manufacturers, such as our TT-3600 Tortilla Production Line, and the BR-1500 Burrito Forming Machine. After market research and testing, ANKO recently launched our QS-2000 Quesadilla Making Machine. This is the world’s first automated machine that produces high quality Quesadillas with great consistency and efficiency rate and minimal required labor. This machine solves production problems including labor shortages, and insufficient productivity, and also allows producers to better allocate their production resources.

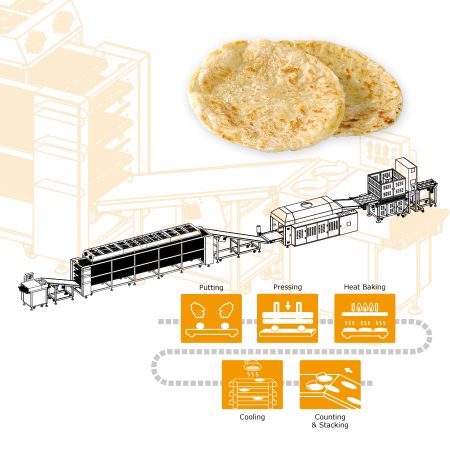

An ANKO Client has been producing a variety of high-quality Roti (Indian style flatbread) and has established a distribution system in wholesale, retail, and supermarkets. During the COVID-19 pandemic, the local food market in the Netherlands experienced a dramatic increase in demand for frozen Roti, as more people were cooking at home. While the company’s production capacity was not able to meet the new demand, they reached out to ANKO and requested assistance to help them transition into automated production. Due to the pandemic and travel restrictions, this client mailed their ingredients to Taiwan and ANKO started production trials and communicated with this client remotely. ANKO’s engineers customized a production solution utilizing ANKO’s SD-97W Automatic Encrusting and Forming machine and APB Pressing and Heating machine for automated Roti production. This production line is compact and highly efficient which exceeded the client’s expectations.

An ANKO client is a major food manufacturer in Kenya and had a business expansion plan to increase market share and revenue in the local food business in Kenya. That was why they wanted to invest in creating a new product - East African Chapati (Paratha). The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO’s products and services were the best. When they initialed the order, ANKO worked diligently to provide customized production line and all the necessary support needed for a successful implementation!

The client's company had gained a firm foothold in India and then he planned to expand into the U.S. market so that having accurate food quality control and standardization, product line extension, productivity improvement are essential. He compared ANKO with other food machine suppliers and found ANKO is superior to them. ANKO has higher market share in India, offers wrapper and filling recipe to meet individual need, and has years' experience in designing food production routes and supply chain integration. Finally, he chose ANKO as their business partner.

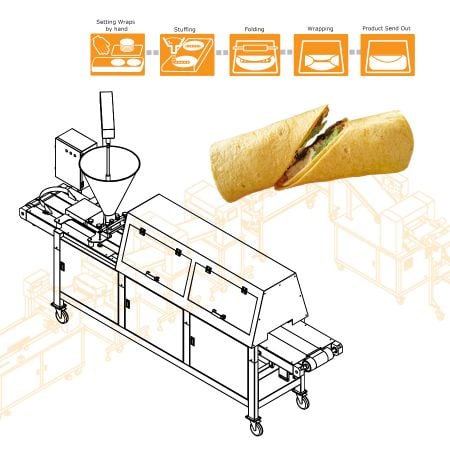

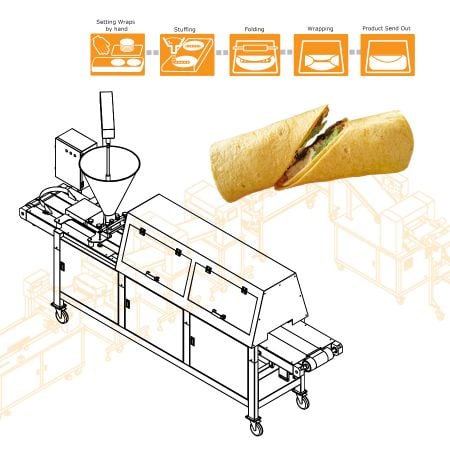

The client has run the company offering Mexican food for over 25 years. They not only have privately-held restaurant chains, but also distribute more than 20 flavors of frozen burritos to supermarkets. However, when their burritos were getting popular, the production capacity of their current production lines could not meet the increasing demand. Then, they found that ANKO has developed burrito forming machine, so they came to Taiwan looking for a solution to increase productivity.

ANKO’s client is a manufacturer of Mexican food products and has distribution in several countries in Latin America and Southern Europe. Burritos are one of the items that this client produces, and this client has decided to transition from manual production to an automated assembly line due to the increasing product demand and labor costs. This client was introduced to ANKO FOOD TECH (AFT) through a referral; and subsequently this client visited AFT for a demonstration, and they were very satisfied with ANKO’s machines, and the products made by our automated system. Additionally, with ANKO’s guidance this company was able to restructure their business, to save on manufacturing costs and focus on their sales and marketing performance for market expansion.