Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

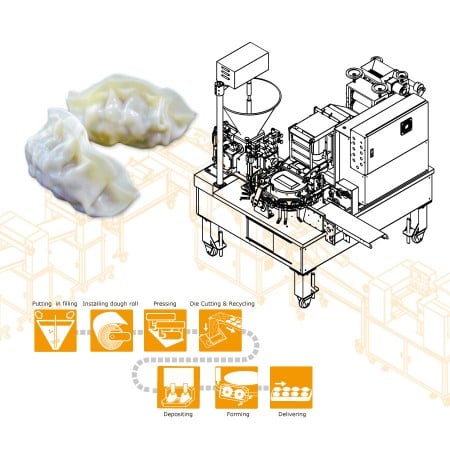

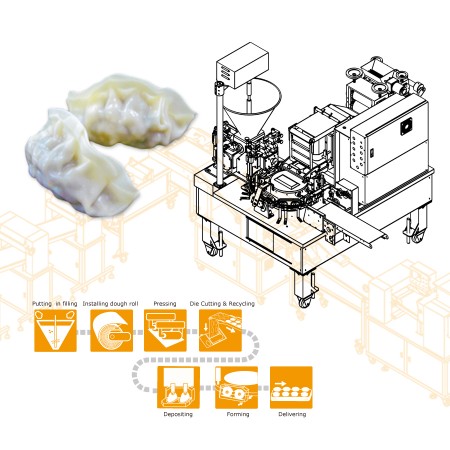

Due to high labor costs and employee management issues, the client, specialized in making Chinese food, started to look for a food processing line for making fried and steamed dumplings. A friend recommended ANKO Food Machine Company to the client. With dumpling making equipment operates automatically, the client is able to increase their production amount with better management. In addition, AFD-888 with CE certificate meets the client's necessary requirement- food safety and hygiene. It is the most important reason that the client chooses ANKO. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

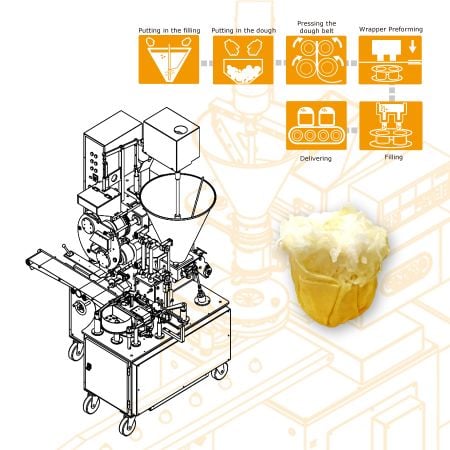

At the restaurant, you see packs of people having their traditional Chinese food, dim sum, in Hong Kong. Dim sum has been a major meal for Hong Kong people. With increasing restaurant business, the owner of a dim sum restaurant would like to expand his production capacity with the tight kitchen space. Quotes from many food machine suppliers were higher than the owner's budget. Only Anko provided reasonable price and excellent quality. ANKO is a food making machine supplier with over 48 years of experience and their solid reputation attracts the owner to ask for their turn-key project solutions.

The client produces a wide range of products from dairy products, frozen ready meals to bakery. They are also devoted to customizing innovative foods. Various flavors and delicate appearances are superior to other competitors' products. However, the frozen food market changes all the time. How can the company strictly control costs while guaranteeing capacity and quality? The knack is the combination of machine-made and hand-made processes. They do not just sell unchanged products but garnish foods and vary flavors to surprise consumers. The combined processes not only save time and costs, but also turn the impression of uninteresting products made by machines. It is our pleasure that ANKO's machinery was chosen to shape their basic products, which means that our efficient and high quality machinery gains favor with the client.

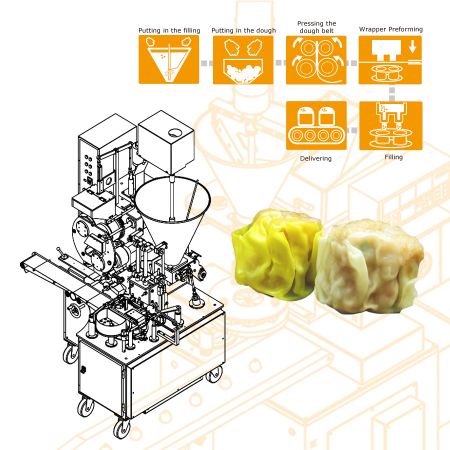

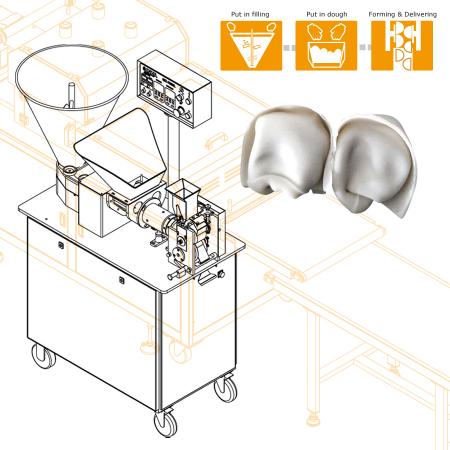

The client has a central kitchen to produce and sell shumai to retailers and takeaways. The growing demand and labor costs prompted him to find an automation solution. Through his friend's introduction, he knew that ANKO is a professional food machine manufacturer. When he visited us for machine test, we used radish shreds in substitution for cassava shreds because cassava is not common in Taiwan. It's also an unprecedented attempt for us. Finally, we were glad to succeed in producing radish shumai by our shumai machine and earned recognition from the client.

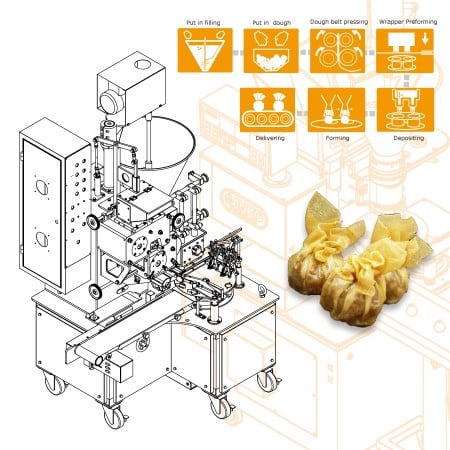

The client runs an eatery next to a school. Two people in total have to be in charge of all works. Due to the fact that more and more people patronized the eatery, the labor shortage prompted him to develop machine production. However, high productivity was not his priority so that he ordered a set of HLT-660 series, which is within budget and enough to achieve his hourly capacity around 5000 pieces. After purchasing the machine, they prepare ingredients in the morning and then arrange production around noon, cooking after taking an order, which can satisfy a large demand during peak hours. (Note: HLT-660 series is no longer available. Please contact us for the updated HLT-700 series.)

The growing demand for frozen food and take-out food has led to intense competition in the Spanish frozen market. The client has run restaurants and sold frozen food to many supermarkets. Due to the expansion of the market, they needed a complete productivity solution that allowed new dumpling making machine to work well with their packing line and comply with food hygiene regulations. ANKO, as a solution provider, has many related experiences and the ability to customize machines, so they decided to cooperate with us. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

20 years ago, a Chinese restaurant opened, serving Shanghai style dim sum which then became popular with the local people. However, the issues of labor shortage, limited capacity, and workload drove the owner to make a change. During his visit to ANKO, he had good experience with ANKO's machine trial service. During the visit, both of us could have a better understanding of each other. Based upon his ideas, concerns, and needs, we customized two forming molds to help him mass-produce shanghai wontons that were complicated to fold by hand. With ANKO's HLT-700XL, now the owner doesn't bother to recruit and train cooks and can increase capacity to meet demands.