Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

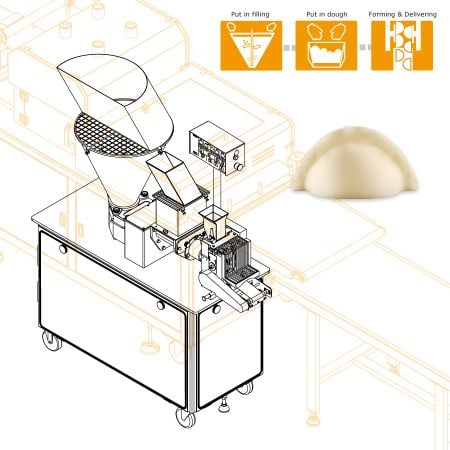

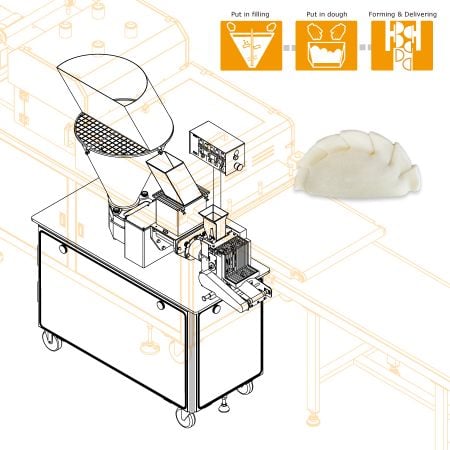

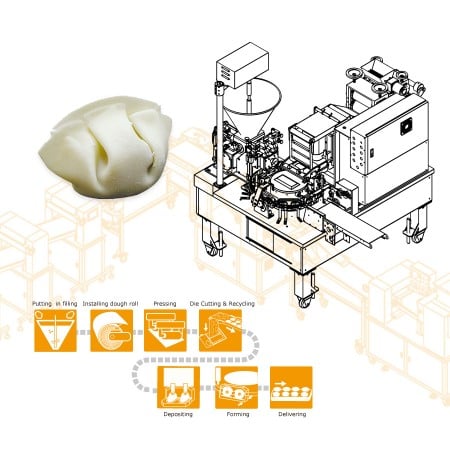

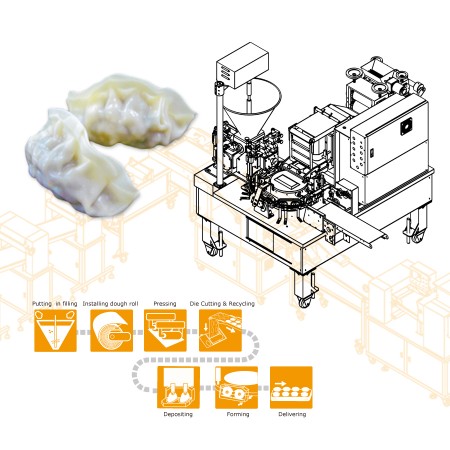

The client operates a central kitchen and restaurant chain in Australia, popular with both locals and tourists. As sales grew and manual production reached its limits, they adopted ANKO’s HLT-700U Multipurpose Filling and Forming Machine to improve efficiency. To meet demand for new flavors and healthier options, the client worked with ANKO to develop custom molds and gluten-free dumplings. Leveraging ANKO’s recipe database and R&D expertise, we ensured stable production, accelerated the product launch, and reduced development costs, helping the client expand their product line and differentiate in the market.

This client is a third-generation Chinese American who inherited his grandfather's wholesale food business in the United States. A few years ago, his company had to adjust to accommodate the changes in the overall marketplace and focused on producing and distributing Chinese cuisines. After thorough market research, the client purchased ANKO's HLT-700U Multipurpose Filling and Forming Machine to make authentic Chinese Dumplings. After nearly a year of market testing, which showed promising sales, the client further invested in the ER-24 Automatic Egg Roll Production Line and AF-589 Conveyor Fryer a year later. ANKO's high-quality and durable food machinery has successfully helped clients excel in authentic Chinese food production and become leaders in the market.

Due to high labor costs and employee management issues, the client, specialized in making Chinese food, started to look for a food processing line for making fried and steamed dumplings. A friend recommended ANKO Food Machine Company to the client. With dumpling making equipment operates automatically, the client is able to increase their production amount with better management. In addition, AFD-888 with CE certificate meets the client's necessary requirement- food safety and hygiene. It is the most important reason that the client chooses ANKO. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

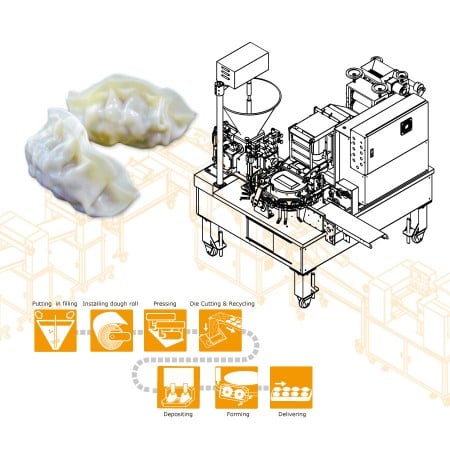

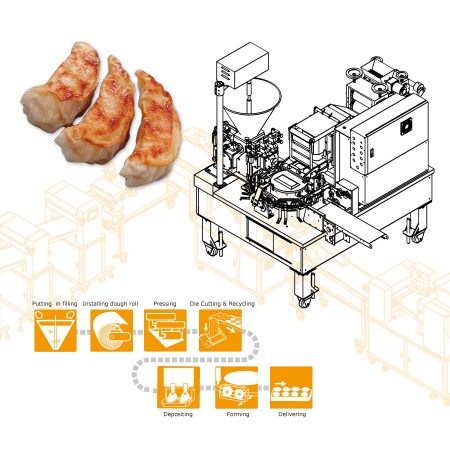

The client, one of our old clients, purchased ANKO's Hargao Forming Machine and Fish Ball Machine. He not only is an OBM of frozen food products but also supply OEM service. In Spanish frozen food market, gyoza was rather new to locals. However, the client was brave expanding an all-new production line on the strength of the well-known brand he created. He hoped gyoza, a dish represents Japanese culture, could be served on the tables in Spain. In order to develop a complete new project, the choice of machine supplier shall be more careful. The client had a pleasant experience of cooperating with us so that he was confident that we were able to plan a whole production line, including machines for preparing ingredients and cooking products such as a steamer, etc. About the gyoza making machine, we recommended him AFD-888, it is with a closing mold device which can produce springier yet firm in taste and more delicate in appearance. The whole project was well prepared and ready to hit the market. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

The client began his business from running a dim sum restaurant, introducing the taste of Chinese cuisine to the Dutch and developing a health-oriented menu. With the growth of business, they established a food processing factory. As looking for equipment, they found that ANKO has years of experience in the field of food equipment and customizing machinery on the basis of individual needs and factory space. Therefore, he decided to cooperate with us. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

The growing demand for frozen food and take-out food has led to intense competition in the Spanish frozen market. The client has run restaurants and sold frozen food to many supermarkets. Due to the expansion of the market, they needed a complete productivity solution that allowed new dumpling making machine to work well with their packing line and comply with food hygiene regulations. ANKO, as a solution provider, has many related experiences and the ability to customize machines, so they decided to cooperate with us. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

To increase capacity and standardize products are the main issues that drive food manufacturers and restaurant owners, including this client, to switch from manual to automatic production. The dumplings served in the company's restaurant chains were made by hand in its own central kitchen. Consumers really liked the handmade dumplings, but 'sold out" was the most important issue with which the company had to deal. Moreover, the size, weight, and taste of handmade dumplings might vary from batch to batch. Using a dumpling maker can both improve capacity and achieve standardization. Therefore, he chose us as the solution provider for the automatic production of dumplings. He also wanted to serve deep-fried dumplings and steamed dumplings to satisfy customers' appetite after increasing capacity.

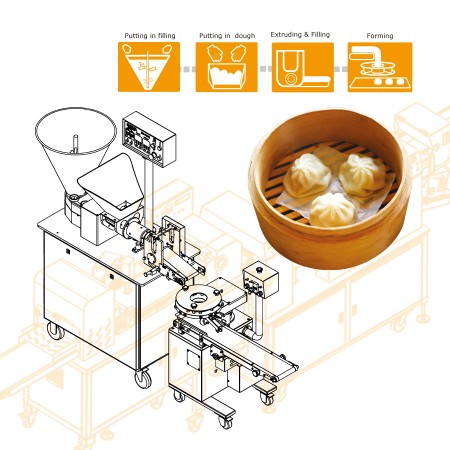

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply and problems with staff management had come out. It took an average of three months for a new employee to become fully productive. Therefore, the client started finding an automatic solution. At first, the client knew ANKO by searching from the Internet and visiting IBA Munich, which is a trade show held in Germany every two years, but he didn't contact us until the next IBA Munich. He placed an order without having a machine trial because he thought ANKO had considerable experience in food machinery. He purchased an HLT-700XL Multipurpose Filling and Forming Machine and an EA-100KA Forming Machine. With these two machines, he could make a wide variety of dishes, such as dumpling, steamed dumpling, crystal dumpling, fun guo, soup dumpling, increase production capacity and decrease labor costs. Moreover, when ANKO's engineer conducted on-side commissioning, our engineer helped solve his problem that soup dumplings had no soup.