Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

This UK-based Indian food manufacturer, specializing in Punjabi Samosas, relied on manual labor to produce 1,000–1,500 pieces daily. With growing competition in the UK's Indian food market, scaling production and boosting revenue became increasingly urgent. After an in-depth consultation, ANKO found no existing machine could mass-produce the pyramid shape of traditional Punjabi Samosas. To help the client gain a competitive edge, ANKO spent over a year developing the world's first PS-900 Punjabi Samosa Forming Machine. Throughout development, the client visited ANKO's Taipei headquarters for filling tests and function validations. This breakthrough enabled automated production, reduced labor costs, and created a differentiated product, strengthening their market position and accelerating brand growth.

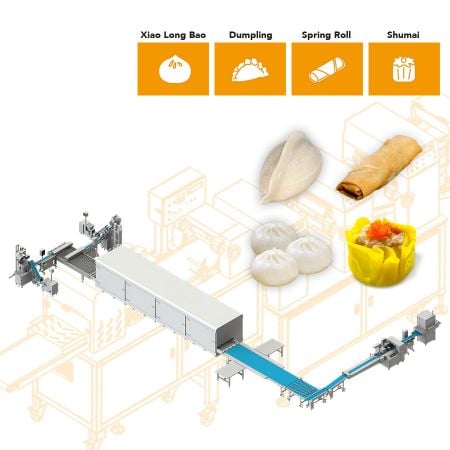

The global food market is rapidly changing. When peak seasons arrive, urgent orders always come quickly. When facing global labor shortages and ever-changing consumer tastes, food companies are eager to find more flexible and efficient production models to respond to market demand. ANKO's newly launched "Integrated Production Line" is designed to resolve the difficulties associated with food manufacturing. Our newly designed production lines include Dumplings, Shumai, Spring Rolls and Xiao Long Bao, providing everything from feeding systems, forming machines, to packaging and various inspection equipment. ANKO's streamlined labor configuration has a daily output of 150,000 pieces! We can also provide solutions for other food products, configuring appropriate production equipment to optimize efficiency and implement a smooth integrated transition.

The client supplies Danish pastries, chapatis, Mille-feuilles and cinnamon rolls, and they wished to upgrade their production capacity in order to increase the sales in fast-food chains.