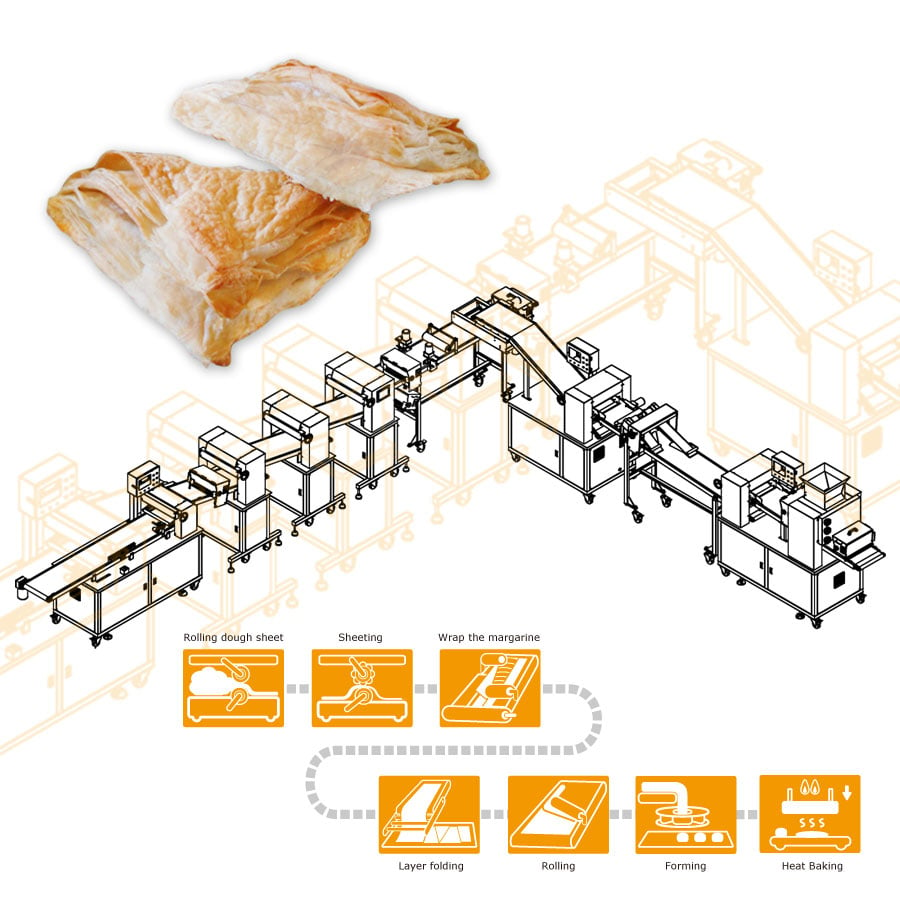

ANKO Danish Pastry Industrial Production Line - Machinery Design for an Indian Company

Danish Pastry

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Danish Pastry Dough Resting Conveyor Design

In the procedure of test before handing over the machine, ANKO found that, after the dough was mixed and kneaded, then rested for 30 minutes on the dough resting conveyor. The character of dough is changed during the resting process, which caused either dough skin to tear apart or become stacked up together. To solve the problem ...(Please contact us to get more information)

Solution 2. CE/UL/CSA certified pastry processing line

For the accessories of the pastry making machine, ANKO utilized companies that were appointed by their client in order to pass government regulations. As a result, the processing equipment was CE/UL/CSA certified, meeting international standards.

Solution 3. Inverter Control Panel Issue Resolve

Inverter control panel is normally dysfunctional when it's - bumped, humid or defective. It may be still useable but not 100% functional when operating a food processing line. This problem may happen when the food processing machine is installed somewhere humid. With our client, the food machine didn't work properly and they contacted ANKO for solutions. To remove the obstacle ...(Please contact us to get more information)

Food Equipment Introduction

- Place the dough into the hopper. Through the special designed rollers the dough will be rolled into a thin dough belt.

- Sheeting and Pressing: The built-in sheeting device saves the client buying one. The dough belt will be rolled again into required size.

- The margarine is extruded onto the dough belt. Through a special designed wrapping mechanism, the margarine is well wrapped inside the dough sheet, which will not leak out to destroy the layers of pastry.

- Sheeting the stuffed dough skin.

- 1st Swing Folding: folding mechanism swings the dough belt with margarine inside onto the delivering conveyer to increase the layers of pastry.

- Pressing and double sheeting: pressing and flatting is one of the major processes during the procedures. During the process, dough and margarine eventually even out.

- 2nd Swing Folding.

- 20 minutes dough resting and then following with a pressing process.

- Triple sheeting.

- Cutting and forming: the edge of dough skin is trimmed to the proper size and ready to be baked.

ANKO's goal is to design a food processing production line that would produce pastries with 100% handmade texture, and is energy saving and cost effective for the client. In addition, the Danish pastry production line meets production capacity requirements for their chain stores' increased sales.

- Solution Proposal

Explore ANKO's Danish Pastry Production Line for Bakery Manufacturers

ANKO did

ANKO Danish Pastry Production Line is tailored to meet specific client requirements. We've addressed design and production challenges, enabling clients to establish a fully automated processing line for large-scale production while reducing labor costs.

ANKO can help you more

Drawing on years of experience in turnkey planning, we assist in building comprehensive production lines, covering ingredient processing, food production, cooking, and packaging devices. Whether you're aiming for increased capacity or efficiency, we provide options for double or triple production lines. Please click Learn More for a detailed overview of our services.

We ensure high-quality service and equipment, with a dedicated agent in India. If you're planning to venture into ethnic food production, our agent can guide you toward a successful food business. Please submit an inquiry below for further assistance.

- Machines

-

LP-3001 - Automatic Layer & Stuffed Paratha Production Line

LP-3001 is food processing equipment that is specifically designed to make pastries with fermentation and lamination processes. The challenge of the design is to produce pastries that would taste like they come from experienced chef's hands. It is about dough's resting time, rolling and pressing, and the mixing of ingredients. With LP-3001, the manufacturer will be able to make western and Asian pastries including Green Scallion Pie, Paratha, Roti Canai, Puff Pastry, Stuffed Paratha, Cronut, Croissant Donut, etc. The high production capacity (550~600KG/hr) would allow high sales amount.

- Video

- Country

India

India Ethnic Food Machine And Food Processing Equipment Solutions

Our food equipment solutions for clients from over 114 countries. You can click on the following categories to view cases. Each case shows how ANKO conducts food machine solutions - from the beginning of ingredient preparation, machine design and manufacture, troubleshooting and after service.

- Category

- Food Culture

Danish pastry is a yeasted, buttery pastry of many layers that you can see everywhere at the bakery. The concept was brought to Denmark by Austrian bakers, where the recipe was partly changed and accommodated by the Danes to their liking, and has since developed into a Danish specialty. From the plain bread to flavored ones, they are great breakfast or dessert pastries to have with a cup of hot tea. The texture is crisp and flaky on the outside, while the center stays soft. Danish pastries were brought to the United States due to the immigration, where they are often topped with fruits or cream cheese or custard filling, and become a popular dessert in the world.

- Handmade Recipe

-

Food Ingredient

Strong Flour/Weak Flour/Yeast/Milk/Egg/Butter/Sugar/Salt/Water

Flour Dough Making

Put an egg, milk, 2/3 flour, salt butter, yeast, all mix together. Leave it for about 2 to 3 minutes, sprinkle a bit of flour and shape it into a dough ball. Let it rest for half or an hour, depending on the temperature and humidity in the kitchen. Grab some cold butter and put some flour, beat it with a stick for 5 minutes, until it has the same consistency as the dough. The dough ball and kneaded cold butter should be the same size. Roll out the dough ball as a sheet to wrap the handled cold butter.

3*3 foldings

Now, the dough is ready to be folded. Use the pastry roller to roll out the dough and make it thin and long, and then fold twice to make 3 layers. (Rest dough for 20 minutes before doing the 2nd time folding). Do it three times with the same dough. In the end, cut to the desired sizes and more rolls and folds after adding filling. Sprinkle sugar on the surface of the pastry, the sugar will make the Danish pastry brown and solid. Put them in the oven and bake for half to 1 hour.

- Downloads

English

English