East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

An ANKO client is a major food manufacturer in Kenya and had a business expansion plan to increase market share and revenue in the local food business in Kenya. That was why they wanted to invest in creating a new product - East African Chapati (Paratha). The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO’s products and services were the best. When they initialed the order, ANKO worked diligently to provide customized production line and all the necessary support needed for a successful implementation!

East African Chapati (Paratha)

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Customized 3-in-1 production line for shelf-stable paratha (extended/prolonged shelf life)

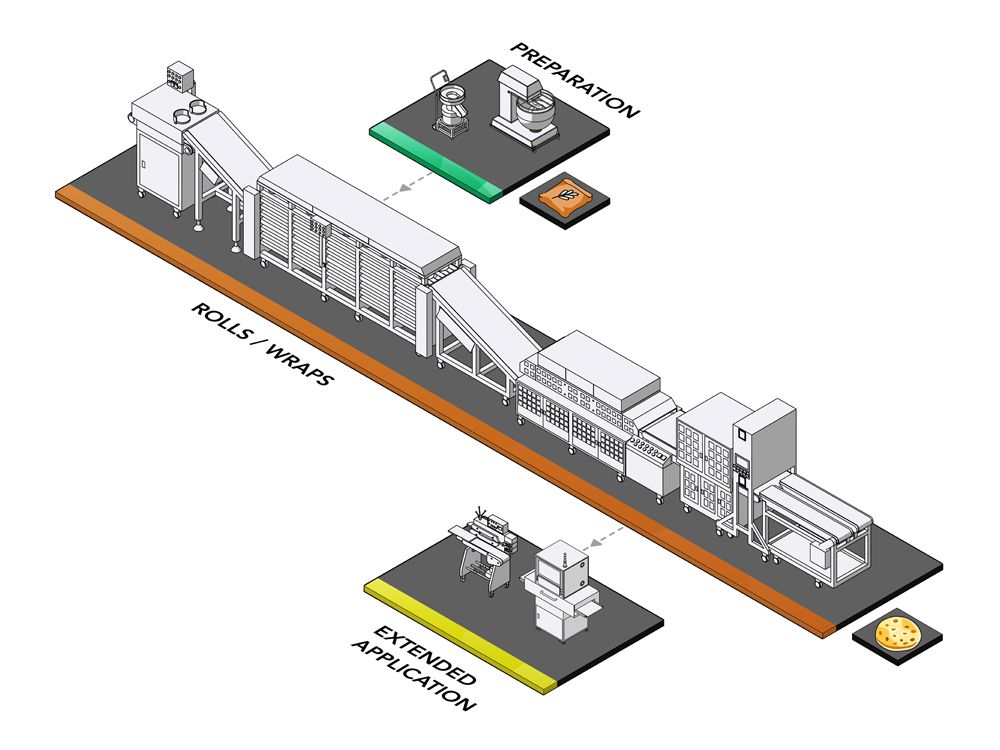

Kenya lacks a sufficient cold chain infrastructure therefore our client wanted to produce a ready-to-eat paratha that has extended shelf life when stored at room temperature. ANKO’s team custom designed a new production line that included 3 different machines: LP-3001 Automatic Layer & Stuffed Paratha Production Line that was used for rolling the dough into a long belt and then forms into individual pieces. The dough then passes through ANKO’s AL-240 Automatic Aligning Machine so it is ready to be plated onto trays and then rested. Finally, the TT-3600 Tortilla Production Line is used to heat-press and bake the flatbreads; the finished products are then chilled; next they are ready to be packaged.

Solution 2. Production line planning with space limits and time restraints.

The 3-in-1 Production Line was initially approved by our client. However, they later realized that their factory didn’t have the correct space for the LP-3001 machine. Thus, ANKO......(Please contact us to get more information)

Food Equipment Introduction

- Place pre-mixed dough into hopper (LP-3001)

- Press dough into a long belt and then form into individual pieces

- Automatic assembly and place on tray with AL-240

- Use TT-3600 for Heat-pressing and baking

- Chilling and stacking for packaging

Customization is the key to successful production

ANKO’s team helped their client to achieve their goals of producing shelf stable ready-to-eat paratha products using minimal labor. Based on more than 46 years of industry experience, ANKO’s team assembled several different machine models to create a customized automatic production line which included multiple temperature control settings to minimize food contamination in each step of the process.

- Solution Proposal

ANKO's Chapati Production Solution Facilitates High-Volume Manufacturing

ANKO did

Our comprehensive Chapati Production Solution includes a dough mixer, the TT-3600 Chapati Production Line, packaging, and food inspection machinery, enabling a production rate of 3,600 pieces per hour. We provide expertise in space allocation, layout design, and workforce planning, ensuring a holistic service for your food business.

ANKO can help you more

Moreover, ANKO's food researchers offer support for new product research and development, transforming your concepts into profitable ventures efficiently. We can optimize recipes to align with your specific requirements. In cases of production challenges, ANKO can guide the implementation of production processes and assist in troubleshooting issues, contributing to your success.

For more inofrmation, please click Learn More or complete the form below.

- Machines

-

ANKO ML Series Dough Mixer

ANKO’s dough mixer is highly efficient for mixing dry and wet ingredients into a homogenized dough. This machine can be used for paratha as well as other breads and pastries. There are also different models that are made to accommodate larger capacities.

ANKO LP-3001 Automatic Layer and Stuffed Paratha Production Line

In this specific case, the LP-3001 was used to produce plain East African Chapati (Paratha) that were around 15-16cm in diameter and 80g in weight. It could also be used to produce stuffed paratha or puff pastries and other tasty foods by simply referring to different parameter settings provided in the production manual.

ANKO AL-240 Automatic Aligning Machine

ANKO’s aligning machine is incorporated into a production line to reduce any possible contamination caused by human contact and reduce unnecessary excessive labor.

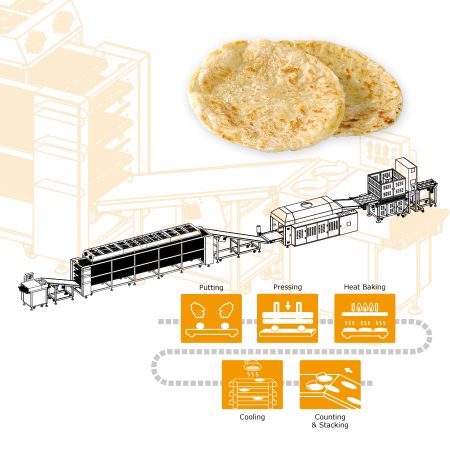

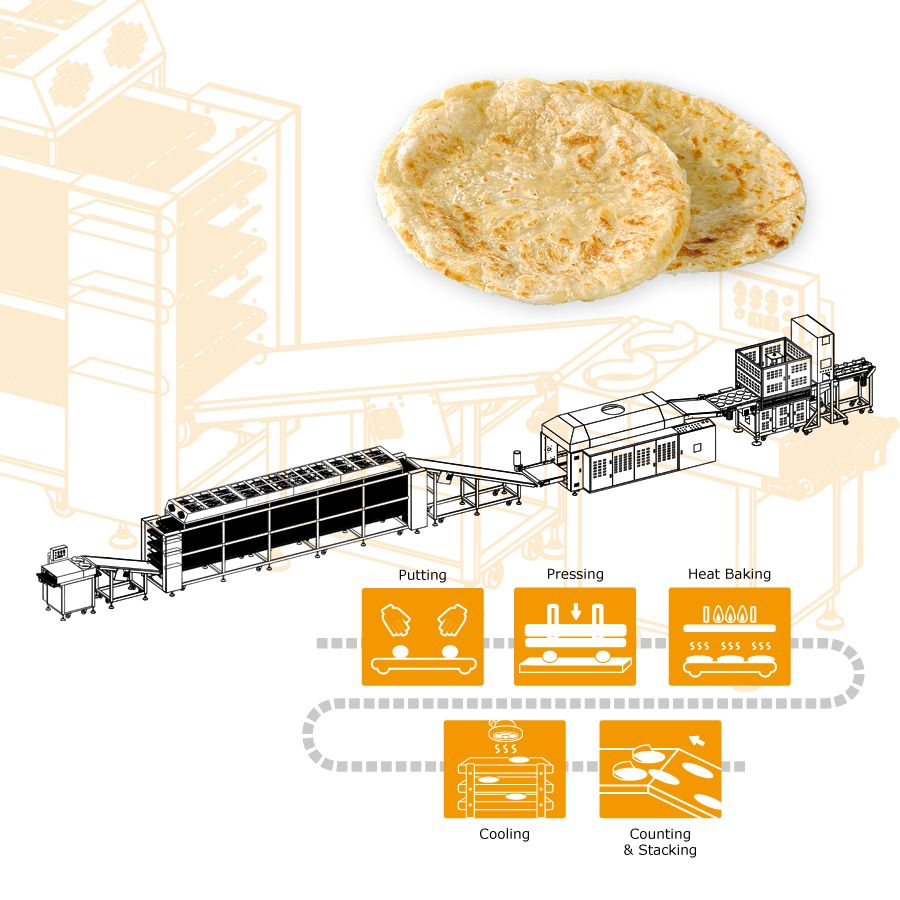

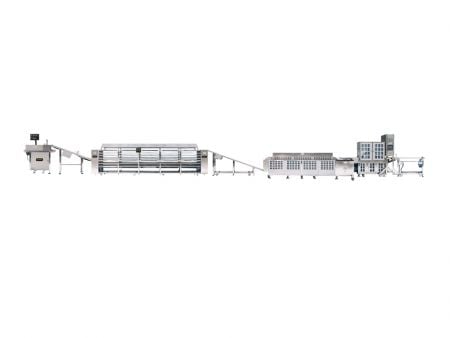

ANKO TT-3600 Production Line

ANKO’s TT-3600 was used for heat-pressing and baking flatbreads in this production line. ANKO’s design also included an automatic counting and stacking function that facilitates the packing process. TT-3600 is suitable for producing other a multitude of flatbreads such as tortilla, roti, etc.

- Video

ANKO’s Customized East African Chapati (Paratha) Production Line - ANKO’s custom designed East African Chapati (Paratha) production line was able to meet our client’s specific production requirements. The client was highly satisfied with ANKO’s production plan, proposal, and creative solutions. Therefore, our customer decided to purchase ANKO’s products and services and has since been pleased.

- Country

Kenya

Kenya Ethnic Food Machine And Food Processing Equipment Solutions

Our food equipment solutions for clients from over 114 countries. You can click on the following categories to view cases. Each case shows how ANKO conducts food machine solutions - from the beginning of ingredient preparation, machine design and manufacture, troubleshooting and after service.

- Category

- Food Culture

Paratha is type of flatbread made with unleavened whole wheat flour; the dough is usually flattened, then pan-fried or deep fried into a flatbread which has multiple layers. Paratha is native to India and commonly consumed Sri Lanka, Pakistan, Nepal, Bangladesh and of course all over India. However, in parts of East Africa, Paratha is made to taste closer to Chapati (another type of Indian flatbread). Both of these are easy to make and are often pan-fried on low heat with a small amount of oil. This staple can be enjoyed with a fried egg, or served with cassava leaf stew, and can also be served with bean soups or meat and vegetable stews. Being so versatile, it can also be used for wraps and many other food delicacies.

- Handmade Recipe

-

Food Ingredient

All purpose and bread flour/Shortening or Cooking Oil/Salt/Sugar/Food grade preservatives/Water

How to make

(1) Mix flour, sugar, and salt, and add Ghee/oil (2) Knead dough to form a soft and sticky texture (3) Put the dough on a board with flour, knead, and rest for about 10 minutes (4) Divide the dough into several pieces and rest for about 30 minutes (5) Using a rolling pin, roll dough out into a circle (6) Put light oil on dough (7) Put dough on a heavily floured plate, then press the dough down (8) Turn dough over and press down and shake off excess flour slightly (9) Shape and coil dough like a circle (10) Cover the dough with a damp cloth and rest for 15 minutes (11) Flatten out coiled dough and roll it out (12) Oil the pan and cook about 3 minutes, and it's done

- Downloads

English

English