Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

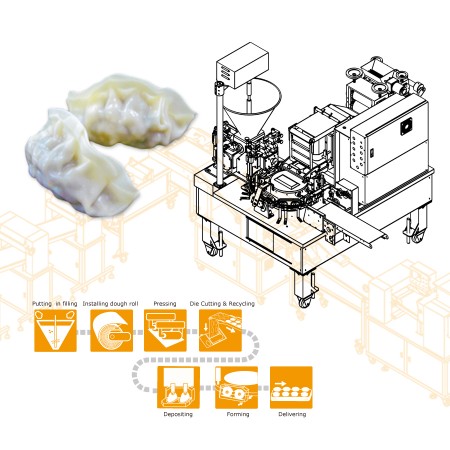

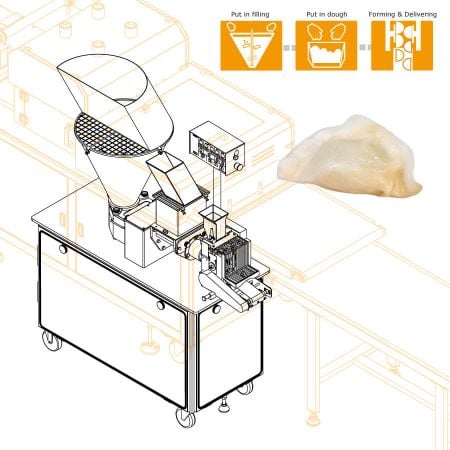

The growing demand for frozen food and take-out food has led to intense competition in the Spanish frozen market. The client has run restaurants and sold frozen food to many supermarkets. Due to the expansion of the market, they needed a complete productivity solution that allowed new dumpling making machine to work well with their packing line and comply with food hygiene regulations. ANKO, as a solution provider, has many related experiences and the ability to customize machines, so they decided to cooperate with us. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

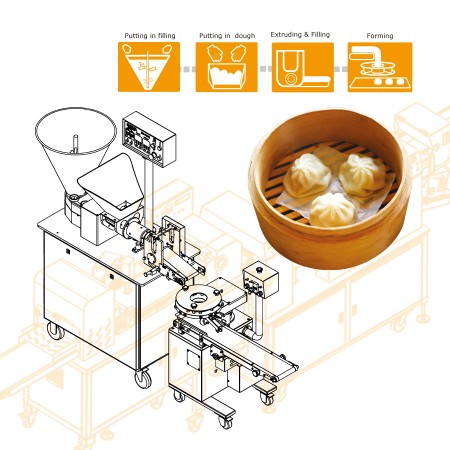

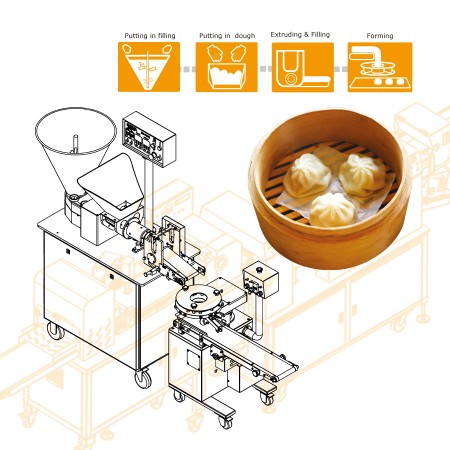

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy recipes to catch customer's heart. With the increasing popularity of dim sum, he began running a food factory. As seeking food equipment, he knew that ANKO has years of experience in the dim sum making machinery and provides customization in accordance with individual needs and factory planning. Therefore, he decided to cooperate with ANKO.

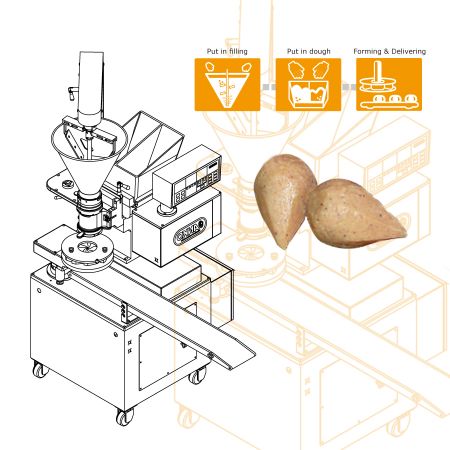

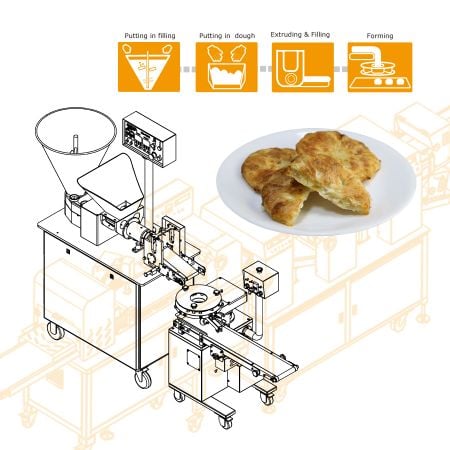

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products online, in supermarkets or deli. Selling products in multi sales channel had leaded to an increasing demand, so the company's owner, via a dealer, had been looking for a supplier who can offer an automated production solution for making kubba. It's always a challenge to make a machine work well with a new recipe. In this case, we had a problem in forming kubba because the crust was too sticky. The just formed kubba would stick to the shutter unit and then be broken while the shutter unit opened. Through recipe and temperature adjustment, ANKO team solved the problem successfully.

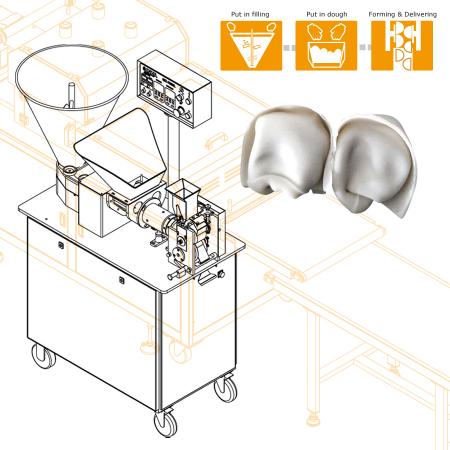

To increase capacity and standardize products are the main issues that drive food manufacturers and restaurant owners, including this client, to switch from manual to automatic production. The dumplings served in the company's restaurant chains were made by hand in its own central kitchen. Consumers really liked the handmade dumplings, but 'sold out" was the most important issue with which the company had to deal. Moreover, the size, weight, and taste of handmade dumplings might vary from batch to batch. Using a dumpling maker can both improve capacity and achieve standardization. Therefore, he chose us as the solution provider for the automatic production of dumplings. He also wanted to serve deep-fried dumplings and steamed dumplings to satisfy customers' appetite after increasing capacity.

20 years ago, a Chinese restaurant opened, serving Shanghai style dim sum which then became popular with the local people. However, the issues of labor shortage, limited capacity, and workload drove the owner to make a change. During his visit to ANKO, he had good experience with ANKO's machine trial service. During the visit, both of us could have a better understanding of each other. Based upon his ideas, concerns, and needs, we customized two forming molds to help him mass-produce shanghai wontons that were complicated to fold by hand. With ANKO's HLT-700XL, now the owner doesn't bother to recruit and train cooks and can increase capacity to meet demands.

Customers want to increase production capacity by moving from manual to automatic production. However, sometimes machine-made dumplings cannot meet their required shape. Either customers have to give up having handmade pleats and delicate patterns or they stay in manual production. Dumpling machine has been ANKO's bestseller. We have received many inquiries about dumpling shapes. "Do you have other more natural patterns?", "Do you have pinching patterns?", "Do you have other pinching patterns?", "Why is the machine-made dumplings not mouth-watering?" and so on. To response these demands, we started a series of development processes.

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply and problems with staff management had come out. It took an average of three months for a new employee to become fully productive. Therefore, the client started finding an automatic solution. At first, the client knew ANKO by searching from the Internet and visiting IBA Munich, which is a trade show held in Germany every two years, but he didn't contact us until the next IBA Munich. He placed an order without having a machine trial because he thought ANKO had considerable experience in food machinery. He purchased an HLT-700XL Multipurpose Filling and Forming Machine and an EA-100KA Forming Machine. With these two machines, he could make a wide variety of dishes, such as dumpling, steamed dumpling, crystal dumpling, fun guo, soup dumpling, increase production capacity and decrease labor costs. Moreover, when ANKO's engineer conducted on-side commissioning, our engineer helped solve his problem that soup dumplings had no soup.

The owner's kompia is so delicious that people are willing to travel a long way to his store in a rural area. However, 1,000-1,200 kompias made by five people a day were not able to meet the demand. That made people feel disappointed and sometimes brought customers into conflict. The client contacted ANKO's Malaysian distributor for SD-97SS, but after a machine trial, ANKO's engineer thought that the HLT-700XL and EA-100KA was more suitable for kompia dough that was firmer for making crispy kompia, while the SD-97SS is suitable for soft fermented dough for creating fluffy texture. Therefore, our engineer immediately decided to use HLT-700XL and EA-100KA to make some samples. With the samples and ANKO's soft power of food and ingredients, the client had complete confidence in us and placed an order.