Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

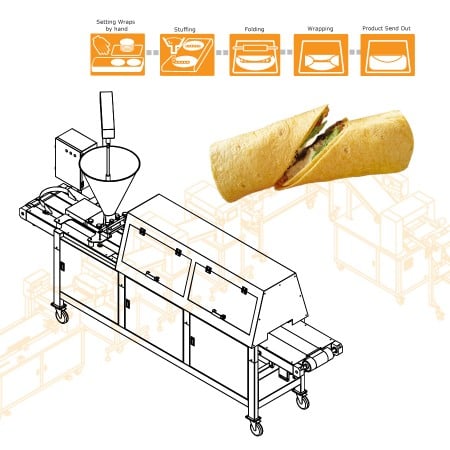

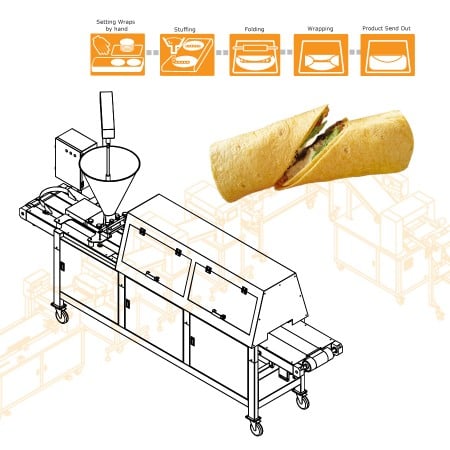

Mexican food is popular in the U.S and a favorite cuisine around the World. ANKO has developed many innovative food machines to supply to Mexican food manufacturers, such as our TT-3600 Tortilla Production Line, and the BR-1500 Burrito Forming Machine. After market research and testing, ANKO recently launched our QS-2000 Quesadilla Making Machine. This is the world’s first automated machine that produces high quality Quesadillas with great consistency and efficiency rate and minimal required labor. This machine solves production problems including labor shortages, and insufficient productivity, and also allows producers to better allocate their production resources.

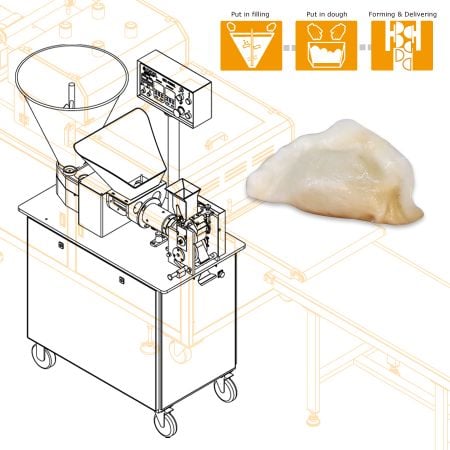

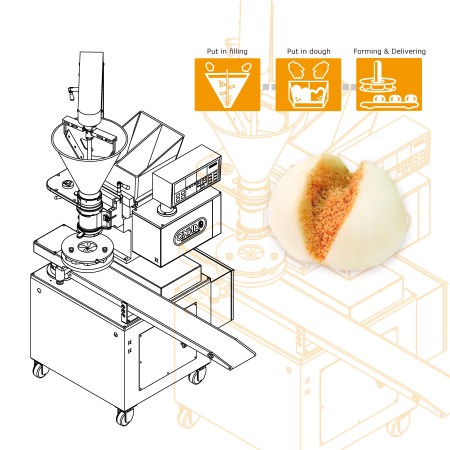

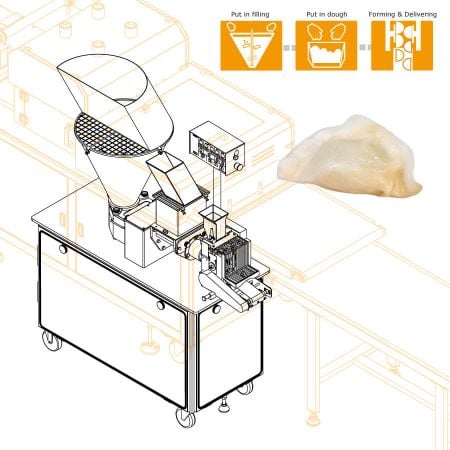

A client and her partners started a business in Singapore. These entrepreneurs later decided to invest in the Chinese Dim Sum business in 2019. Initially they purchased equipment from a supplier in China, but the equipment was not as user friendly and required multiple employees to operate. Additionally, they encountered many difficulties and problems during their manufacturing processes. Fortunately, this very same client found ANKO. ANKO is a company that is dedicated to Quality and Productivity while offering customized production solutions for various food products and catering to each of our client’s unique requirements. This client purchased ANKO’s HLT-700XL and EA-100KA for producing dumplings and Xiaolong soup dumplings. The company supplies many schools with dumplings, and they are also working with many central kitchens. With ANKO’s equipment this client was able to establish their own brand since have enjoyed great success.

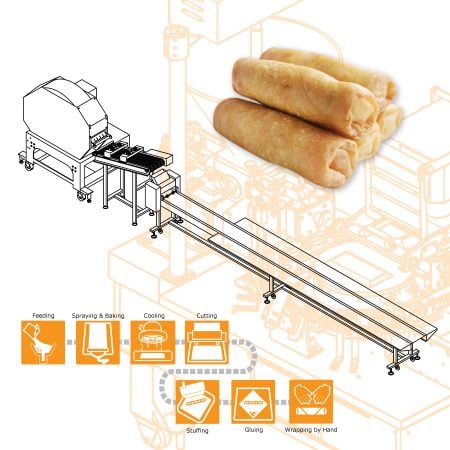

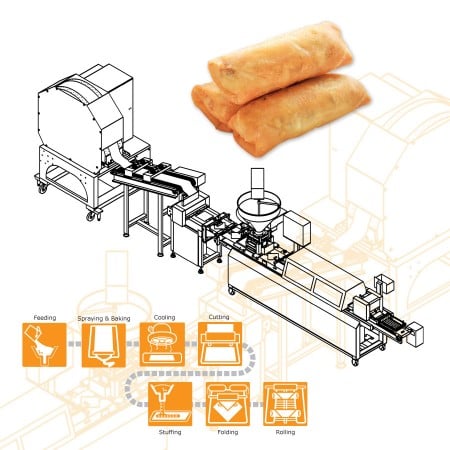

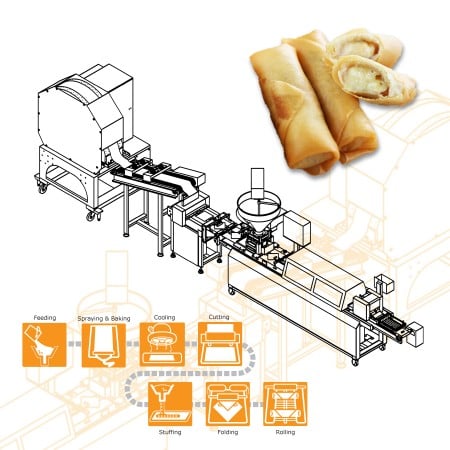

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to devote extra time on reprocessing each sheet before use, and reaching the thickness with the feeling of satiety. In order to increase overall efficiency, the initiation to implement his own pastry sheet production line rooted in his mind. He then found a Taiwanese food machine manufacturer called ANKO, which has years of experience in researching and developing food machinery. Not only can they modify the recipe according to the accessible local ingredients, but most importantly to solve the production problems that the client faced. Which is to produce extra thick spring roll wrapper that is 35 grams in weight and 0.9 mm in thickness.

The client has run Korean restaurants in Panama, where are viewed by local people as a good place to satisfy your taste buds and stomach. At that time, the owner wanted to serve more dishes in his restaurants and sell on other channels. To achieve the goal, his central kitchen had to supply various kinds of food and increase production capacity. Moreover, with the government's protectionist policies, he thought buying a machine would be good investment. Then, someone introduced ANKO and our HLT Series Multipurpose Filling and Forming Machine to the owner. During his visit to ANKO for machine trial testing, he realized that ANKO is reliable and able to offer customization and turnkey services. Finally, he chose ANKO as his business partner to grow with him.

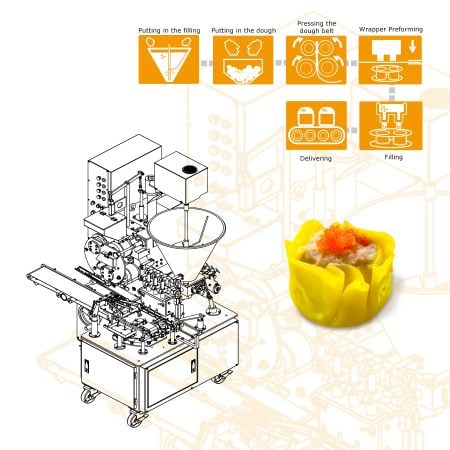

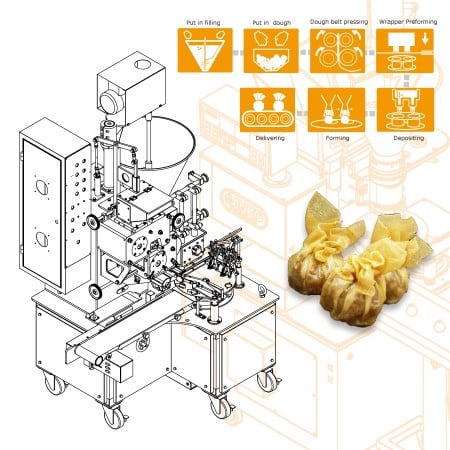

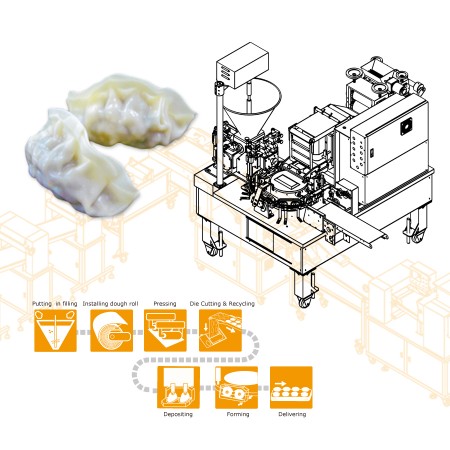

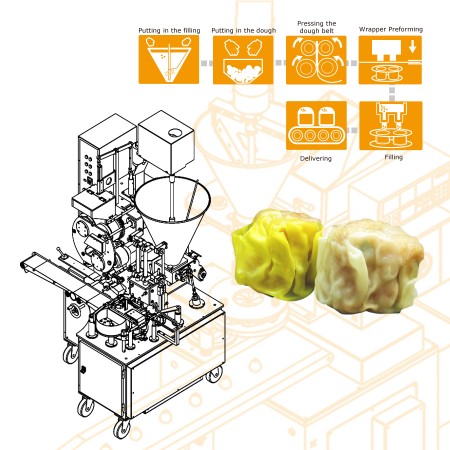

The client is a co-packer, who has been contracted by many food companies to produce Chinese food and dim sum. He has been using ANKO's double-line shumai machine for years and gives ANKO credit for the high quality machine. Recently, due to the COVID-19 lockdown, the demand for frozen food and ready-to-eat food is growing while people are unable or less willing to eat in restaurants. Therefore, a chain restaurant, who is well known for its shumai, was seeking new opportunities. The company would like to sell ready-to-heat shumai in convenience stores and supermarkets. It then contracted our client to produce the delicious shumai. As a result, our client planned to purchase another shumai machine. He said, "if you have triple-line shumai machine, we'll definitely buy one. It will be perfect."

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service. With the gourmet spring roll was getting more popular, insufficient employees could not meet higher demands. At that time, the client was actively seeking a food machine supplier possessing high quality machines and professional services. They heard ANKO produced stable and high productivity spring roll machine. Finally, They decided to rely upon ANKO to increase productivity.

The client has production lines for bakery and ethnic food, including baozi, siomay, hargao, bread, etc. In order to provide the most fresh and best quality food to customers, they have food factories, central kitchens, packaging production line, cooling and frozen facilities. Because their present products stably make profits, they plan to expand the other Chinese dim sum production line to produce spring roll. Hope it can create a new market. Prior to this expansion, the client bought several machines from ANKO for making baozi and satisfied with machine's quality and ANKO's after-sales service, so that ANKO spring roll wrapper machine, which production capacity is high and stable, is exactly what they want. Therefore, it is our pleasure to cooperate with them and satisfy their requirements.

In Canada, the frozen food market is in the keen competition. Locals prefer buying take-out foods or instant foods to save time. The client runs chain restaurants and receives frozen food orders from supermarkets. Because of increasing demands, except for the original machine they bought from ANKO for making wonton, fried dumpling, shumai and the like, they would like to purchase spring roll machinery for expanding their production lines. (The SR-24 is no longer available. The new model is SR-27 machine.)

The Canadian frozen food market is facing keen competition. Locals prefer ordering out or taking away food so as to save time. Ready-meal is also a choice for many families. In the client's chain restaurants, wonton soup is one of the most popular combinations. With the growing number of branch stores, they have to prepare more and more pieces of wonton every day. Therefore, they start using ANKO's wonton machine to automatically produce wonton, and then they freeze cooked wonton and deliver to every restaurant, which enable a rapid response to the increasing demand.

The company's cheese roll features its thin pastry made of batter. Compare to Chinese spring roll, they are quite similar in the handmade production and crispy taste. This cooperation is not the first time. The client had bought our other machine types and was satisfied with their quality and productivity. This time, through our customized services and trials, we followed his recipe and successively produced cheese rolls via our cheese spring roll production line. Therefore, he still purchased our machine without hesitation to meet growing demands. (The SR-24 is no longer available. The new model is SR-27 machine.)

The client has a central kitchen to produce and sell shumai to retailers and takeaways. The growing demand and labor costs prompted him to find an automation solution. Through his friend's introduction, he knew that ANKO is a professional food machine manufacturer. When he visited us for machine test, we used radish shreds in substitution for cassava shreds because cassava is not common in Taiwan. It's also an unprecedented attempt for us. Finally, we were glad to succeed in producing radish shumai by our shumai machine and earned recognition from the client.

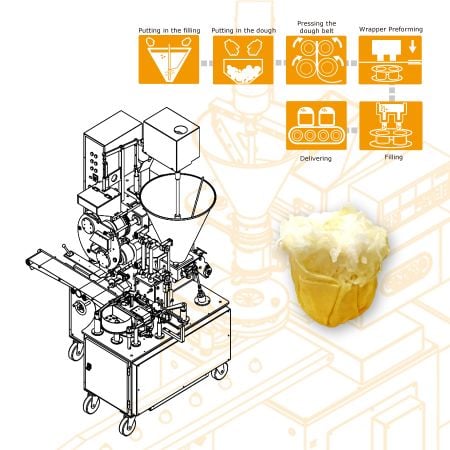

The client operates an air catering company. They offer airline meals to many flights for serving tens of thousands of passengers who travel in and out of China. Shrimp dumpling is an exquisite dish just for business and first class passengers. Due to its complex procedure, rising wages in China, and growing demand, they decided to automate the production of shrimp dumpling. ANKO's Automatic Har Gow Forming Machine manufactures 2,000 pieces per hour and delivers standardized quality control, stable production, simple maintenance and care. They are key factors that contribute to the cooperation.

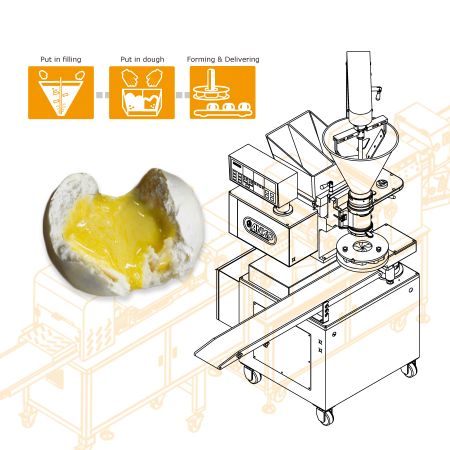

The dining group operates Cantonese restaurants, hot pot buffets, and Japanese buffets for satisfying various consumers. They used to make their food products by hand. With more and more restaurants opened, the continuing growth in demand for steamed custard buns in all types of their restaurants prompted the company to invest in a new machine to extend its offerings. it's a turn to transform handmade into automatic production. Chefs hoped to maintain food quality while cutting cost so that they found ANKO. We have the largest market share in Taiwan food machine industry and our machine can help them meet the growing demand. After testing our SD-97W, they are satisfied with the multifunctional encrusting and forming machine which offers them the flexibility in production. In addition to steamed custard bun mentioned above, they also use the machine to produce sesame balls.

The growing demand for frozen food and take-out food has led to intense competition in the Spanish frozen market. The client has run restaurants and sold frozen food to many supermarkets. Due to the expansion of the market, they needed a complete productivity solution that allowed new dumpling making machine to work well with their packing line and comply with food hygiene regulations. ANKO, as a solution provider, has many related experiences and the ability to customize machines, so they decided to cooperate with us. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

The client sells a great variety of foods. Although glutinous rice ball was not one of the main products, he needed a solution to produce glutinous rice balls effectively. Therefore, he visited ANKO's booth at a Hong Kong exhibition. Compared to other glutinous rice balls, the client's filling recipe contains more ingredients, including peanut powder, coconut powder, and sugar powder, which makes workers hard to fill the same ingredient quantities into each glutinous rice ball. Nevertheless, it is also difficult for machine to extrude powder filling because it easily tends to clump up and clog the filling system. Therefore, for making stuffed food with powder filling, ANKO's Automatic Encrusting and Forming Machine with a special designed powder filling system is highly recommended.

The client has run the company offering Mexican food for over 25 years. They not only have privately-held restaurant chains, but also distribute more than 20 flavors of frozen burritos to supermarkets. However, when their burritos were getting popular, the production capacity of their current production lines could not meet the increasing demand. Then, they found that ANKO has developed burrito forming machine, so they came to Taiwan looking for a solution to increase productivity.

ANKO’s client is a manufacturer of Mexican food products and has distribution in several countries in Latin America and Southern Europe. Burritos are one of the items that this client produces, and this client has decided to transition from manual production to an automated assembly line due to the increasing product demand and labor costs. This client was introduced to ANKO FOOD TECH (AFT) through a referral; and subsequently this client visited AFT for a demonstration, and they were very satisfied with ANKO’s machines, and the products made by our automated system. Additionally, with ANKO’s guidance this company was able to restructure their business, to save on manufacturing costs and focus on their sales and marketing performance for market expansion.

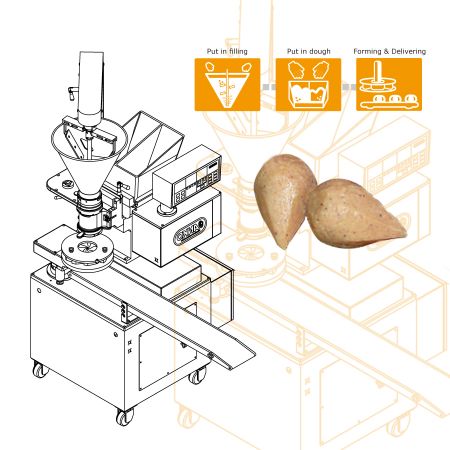

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products online, in supermarkets or deli. Selling products in multi sales channel had leaded to an increasing demand, so the company's owner, via a dealer, had been looking for a supplier who can offer an automated production solution for making kubba. It's always a challenge to make a machine work well with a new recipe. In this case, we had a problem in forming kubba because the crust was too sticky. The just formed kubba would stick to the shutter unit and then be broken while the shutter unit opened. Through recipe and temperature adjustment, ANKO team solved the problem successfully.

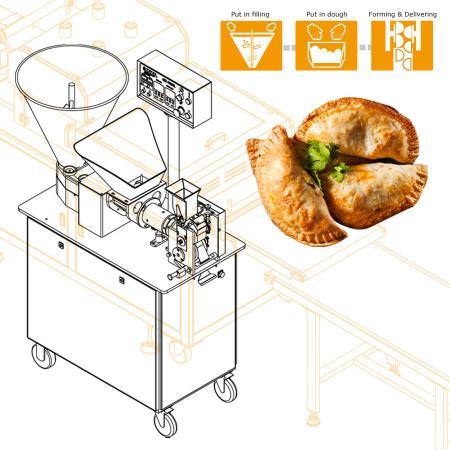

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products online, in supermarkets or deli. Selling products in multi sales channel had leaded to an increasing demand, so the company's owner, via a dealer, had been looking for a supplier who can offer an automated production solution. He was satisfies with ANKO's HLT-700XL model after conducting a test run at ANKO Taiwan headquarters. However, when the machine was commissioned in Egypt, dough was inelastic and couldn't be formed by the machine. The causes might be the characteristics of dough, the weather, or the effect of temperature and humidity. Fortunately, our engineer, who has many years' experience, immediately found the problem and adjusted the dough ingredients. Afterwards, the dough could be processed by the sambousek making machine normally.

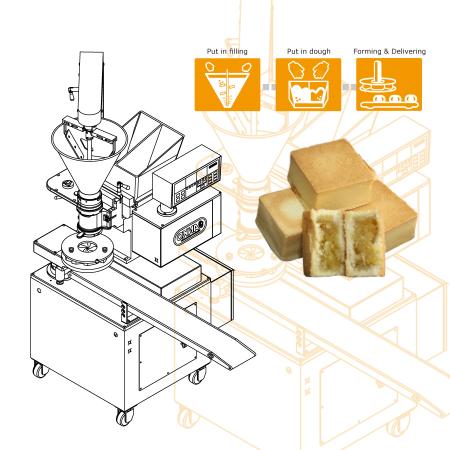

It is a food and beverage company, producing frozen and fresh food, and owning over 30 casual dining restaurants. Most materials of the company's products are from its own farms. With the concept of providing organic food and additive-free products to consumers, the owner insists on growing plants with organic farming. The owner found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell them in his retail stores. However, he had no experience in making pineapple cakes. After having a discussion, we proposed a pineapple cake tailor-made total solution to him, including pineapple cake recipe, equipment, and training. Finally, he entrusted ANKO with the new product line.

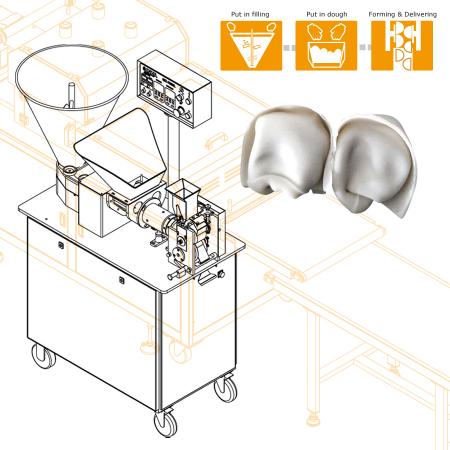

To increase capacity and standardize products are the main issues that drive food manufacturers and restaurant owners, including this client, to switch from manual to automatic production. The dumplings served in the company's restaurant chains were made by hand in its own central kitchen. Consumers really liked the handmade dumplings, but 'sold out" was the most important issue with which the company had to deal. Moreover, the size, weight, and taste of handmade dumplings might vary from batch to batch. Using a dumpling maker can both improve capacity and achieve standardization. Therefore, he chose us as the solution provider for the automatic production of dumplings. He also wanted to serve deep-fried dumplings and steamed dumplings to satisfy customers' appetite after increasing capacity.

20 years ago, a Chinese restaurant opened, serving Shanghai style dim sum which then became popular with the local people. However, the issues of labor shortage, limited capacity, and workload drove the owner to make a change. During his visit to ANKO, he had good experience with ANKO's machine trial service. During the visit, both of us could have a better understanding of each other. Based upon his ideas, concerns, and needs, we customized two forming molds to help him mass-produce shanghai wontons that were complicated to fold by hand. With ANKO's HLT-700XL, now the owner doesn't bother to recruit and train cooks and can increase capacity to meet demands.

Customers want to increase production capacity by moving from manual to automatic production. However, sometimes machine-made dumplings cannot meet their required shape. Either customers have to give up having handmade pleats and delicate patterns or they stay in manual production. Dumpling machine has been ANKO's bestseller. We have received many inquiries about dumpling shapes. "Do you have other more natural patterns?", "Do you have pinching patterns?", "Do you have other pinching patterns?", "Why is the machine-made dumplings not mouth-watering?" and so on. To response these demands, we started a series of development processes.

In order to increase production capacity, the client switched from manual to automatic production and bought a semi-automatic siomay machine. At first, we recommended a single-line automatic siomay machine to him, but, taking many factors into consideration, he decided to have a semi-automatic siomay machine. Just two years later, the number of his restaurants had tripled. Therefore, he purchased an automatic double-line automatic siomaiy machine without much thinking.