Automatic Spring Roll Wrapper Machinery Design to Solve Labor Shortage for a South African Company

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service. With the gourmet spring roll was getting more popular, insufficient employees could not meet higher demands. At that time, the client was actively seeking a food machine supplier possessing high quality machines and professional services. They heard ANKO produced stable and high productivity spring roll machine. Finally, They decided to rely upon ANKO to increase productivity.

Spring Roll Wrapper

ANKO Team Research Problem Solving or Solution Delivery

After deep-frying, the spring roll wrapper became unsatisfying semi-transparent.

Spring roll wrappers should have soft and delicate lines and tactilities as well as beautiful color. However, in this case, the wrappers were too thin to be deep-fried. In first test, ANKO engineer noticed that they became unsatisfying semi-transparent texture. Our engineer tried 2 solutions:

1. Decrease the percentage of ...(Please contact us to get more information)

2. Increase the thickness of ...(Please contact us to get more information)

Finally, we meet the client's requirment about appearence and taste.

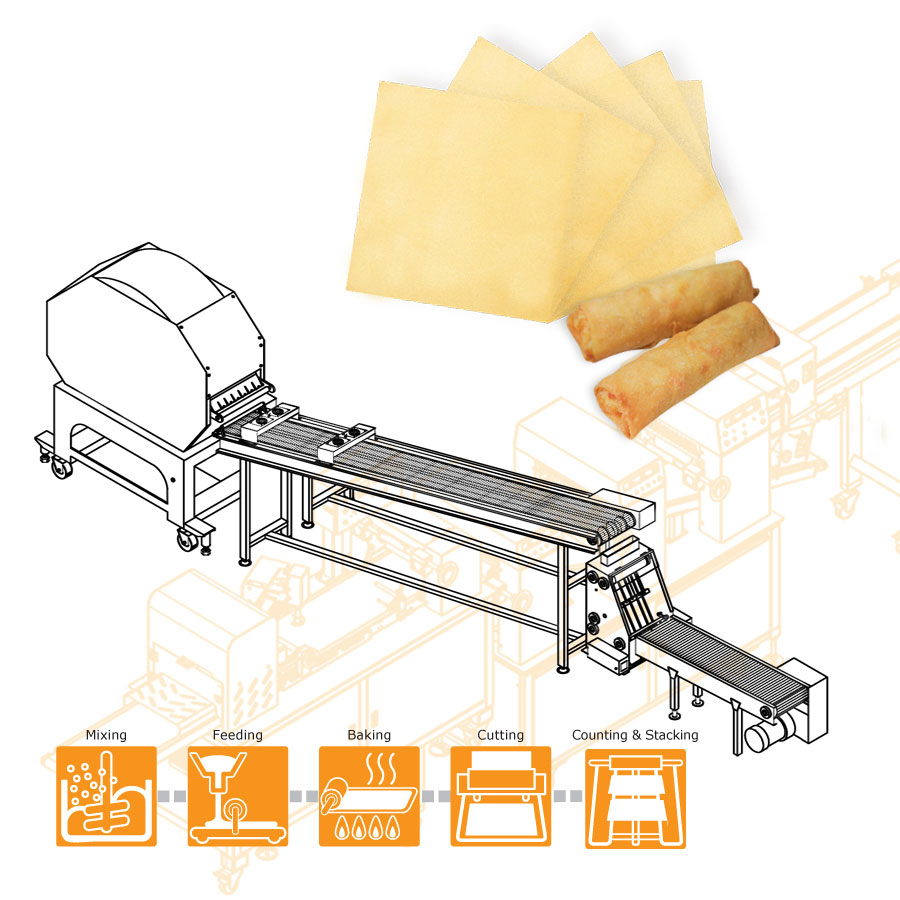

Food Equipment Introduction

- Pour well mixed batter into batter tank.

- Set control panel and make sure the temperature and condition of baking drum.

- Bake batter into wrapper belt.

- Cool wrapper belt via fans.

- Cut wrapper belt into preferred size.

- Stack cut wrappers.

Fundamental of Design

- Increase spring roll productivity. ANKO recommends an automatic spring roll and samosa pastry sheet machine, stable and productive, which productivity is up to 2700 pcs per hour, satisfying the client's requirement.

- Improve product quality. ANKO sheet machine not only prevents unstable food quality produced by hand, but also provides valuable function to adjust wrapper size as you wish

- Standardize every single sheet. More stable and standard sheets than handmade ones are produced and automatically stack and convey to the employees' hands.

- The client sees their food quality as a top priority and insists to provide customers with the most safety and reliable food. From the first procedure, ANKO team has borne the thought in mind and devoted ourselves to design SRP Series machine. It is capable of producing handmade-like products in texture and taste and stabilizing productivity.

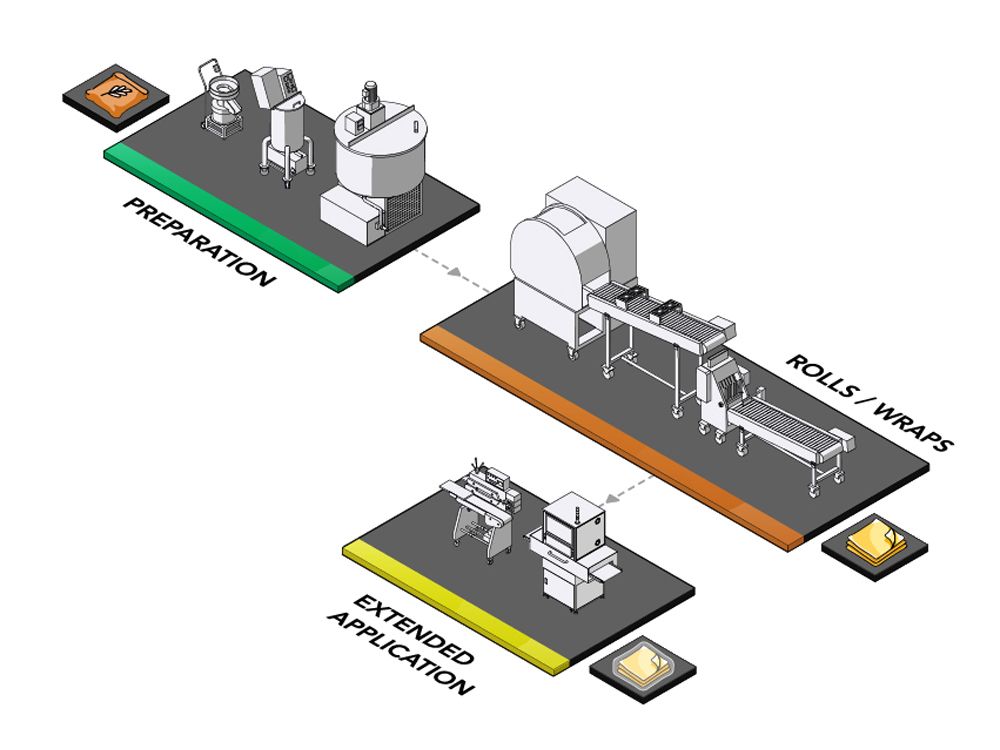

Processing Line Planning

- Sieving

- Mixing

- Spring Roll Equipment

- Sealing

- Solution Proposal

Optimize Your Manufacturing Operations Using ANKO's Spring Roll Wrapper Production Solution

ANKO did

ANKO comprises a comprehensive automatic spring roll wrapper production line which include mixer, forming machine, to packing and food inspection machines to save your time searching and inquiring machines one by one. To ensure that the solution proposal is suitable for you, we offer a Machine Trial run to test your recipe.

ANKO can help you more

If your recipe does not fit with ANKO's Spring Roll Wrapper Production Solution, our food researcher can assist with the ratio of Spring Roll Wrapper, recipe modification, and food preservation approach, etc. Moreover, there’s an in-house Food Lab built for various food-related testing, such as frying or baking, to increase the accuracy of the test results.

For more information, please click Learn More or complete the form below.

- Machines

-

SRP Series Automatic Spring Roll And Samosa Pastry Sheet Machine

As pouring batter into the batter tank, it can be baked immediately at a high temperature through the baking machine, designed by ANKO R&D team. Then, the baked wrapper belt will be cooled at once, ready to be cut and stacked up. The cutting machine is automatic and flexible; simply changing machine parts and setting data can produce preferred wrapper size. 2700-pcs-per-hour high productivity and standardized size products bring the client the greatest benefit as well as solve the problem of insufficient employees.

SRP Series Automatic Crepe Machine

ANKO R&D team has intended to design an automatic spring roll sheet machine to follow up the diversified development of food market. This machine is able to produce different kinds of food wrappers through machine parts changes and data settings. With one machine only, finished products vary from spring roll to crepe sheet, Samosa sheet, Blini, Blintzes, Nalesniki, etc.

- Video

- Country

South Africa

South Africa Ethnic Food Machine And Food Processing Equipment Solutions

Our food equipment solutions for clients from over 114 countries. You can click on the following categories to view cases. Each case shows how ANKO conducts food machine solutions - from the beginning of ingredient preparation, machine design and manufacture, troubleshooting and after service.

- Category

- Food Culture

Since Spring rolls had become a tradition, they have gradually inherited the changes along with the times and evolved with Chinese history. And depending on regions and traditions, Chinese developed many ways of preparing spring rolls to enjoy them with a twist. For example, sweet spring rolls can make perfect teatime snacks or desserts; while these savory rolls are fun finger foods or can even be a main dish in a meal.

Deep-frying is the most popular way to preparing spring rolls. By wrapping various ingredients in a fine layer of flour pancake, then deep-fry till its golden brown and crispy; it's almost irresistible and hard not to lay your fingers on them for more. Therefore, neighboring countries such as Korea and Japan have also adapted this traditional delicacy, and it had almost become a staple and a favorite dish in almost all Chinese restaurants in the world.- Handmade Recipe

-

Food Ingredient

All Purpose Flour/Salt/Water

How to make

(1) Add flour and salt in a large bowl and then pour in water. Stir until dissolved. (2) Strain the batter to remove any lumps. (3) Spread a pan with oil. (4) Brush batter on the pan. (5) Cook until the edges curl slightly and set aside.

- Downloads

English

English